A Brief Analysis of the Application of Decanter Centrifuges in Juice Separation

Introduction

Juice separation is a critical step in the juice production process, directly affecting the purity and quality of the juice. As an efficient solid-liquid separation device, the decanter centrifuge plays a significant role in the field of juice separation. This article will briefly analyze the application of decanter centrifuges in juice separation from the perspectives of working principles, advantages, and specific applications.

### **A Brief Analysis of the Application of Decanter Centrifuges in Juice Separation**

#### **Introduction**

Juice separation is a critical step in the juice production process, directly affecting the purity and quality of the juice. As an efficient solid-liquid separation device, the decanter centrifuge plays a significant role in the field of juice separation. This article will briefly analyze the application of decanter centrifuges in juice separation from the perspectives of working principles, advantages, and specific applications.

---

#### **1. Working Principles of Decanter Centrifuges**

Decanter centrifuges separate solid particles (such as pulp and pomace) from liquids in juice through the centrifugal force generated by high-speed rotation. Their core components include:

1. **Drum**: A high-speed rotating cylinder responsible for generating centrifugal force.

2. **Screw Conveyor**: Discharges the separated solid particles from the drum.

3. **Differential Speed Device**: Adjusts the speed difference between the screw conveyor and the drum to ensure separation efficiency.

**Working Process:**

1. Juice enters the drum through the feed pipe.

2. Under centrifugal force, solid particles settle on the inner wall of the drum, while the liquid is discharged through the overflow port.

3. The screw conveyor pushes the solid particles toward the discharge port, achieving solid-liquid separation.

#### **2. Advantages of Decanter Centrifuges in Juice Separation**

1. **High-Efficiency Separation**

Decanter centrifuges can quickly separate solids and liquids in juice, with large processing capacity, making them suitable for large-scale juice production.

2. **High Automation**

Equipped with automatic control systems, the device is easy to operate and reduces manual intervention.

3. **Strong Adaptability**

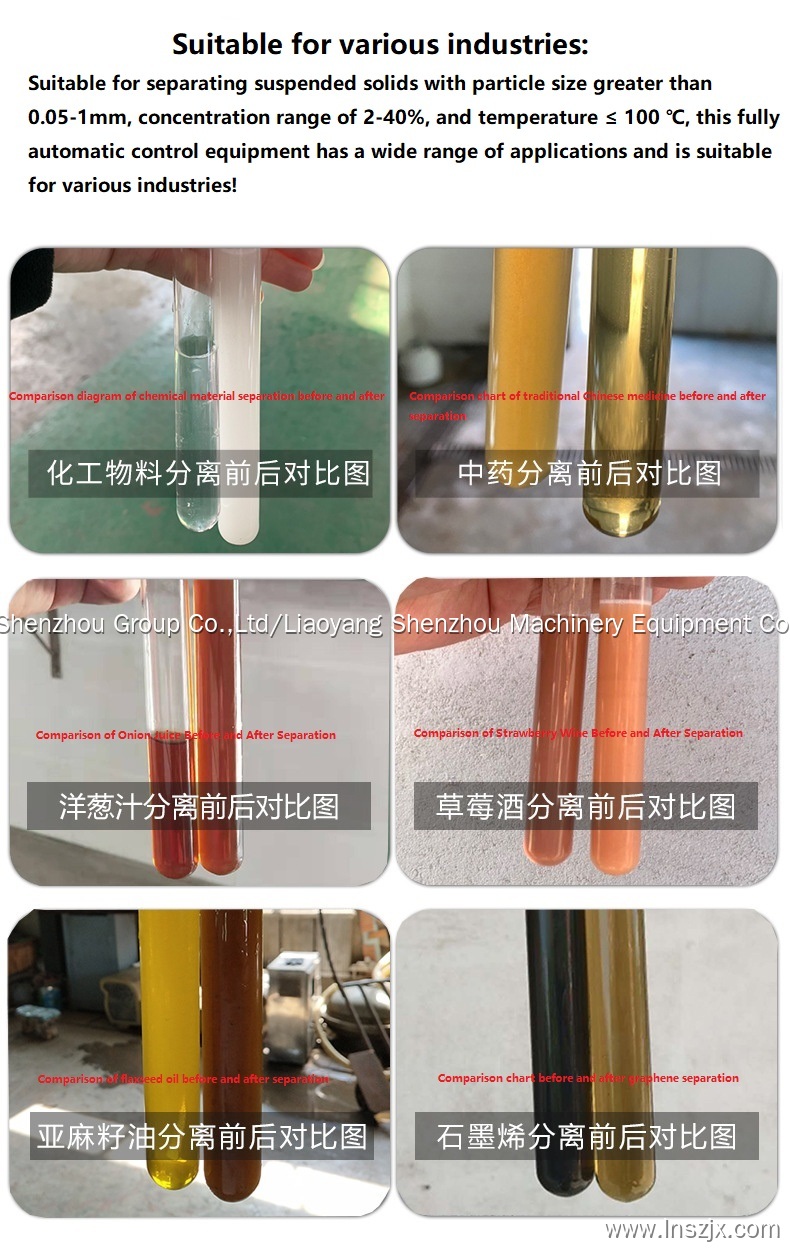

Capable of handling juices of different types and concentrations, suitable for the separation of various fruit juices.

4. **Energy Saving and Environmental Protection**

By recovering solid particles (e.g., pomace) from juice, it reduces waste emissions and enables resource reuse.

5. **Compact Design**

Compared to traditional filtration equipment, decanter centrifuges have a compact structure, saving space.

---

#### **3. Specific Applications of Decanter Centrifuges in Juice Separation**

1. **Pulp Separation**

- Used to separate pulp from juice, improving the clarity of the juice.

- Suitable for the production of juices containing pulp, such as orange juice and apple juice.

2. **Pomace Dewatering**

- Used to dewater pomace generated during juice production, reducing pomace volume for easier transportation and disposal.

- The dewatered pomace can be used as animal feed or organic fertilizer.

3. **Juice Clarification**

- Used to separate tiny solid particles from juice, improving the transparency and taste of the juice.

- Suitable for the production of juices requiring high clarity, such as grape juice and pear juice.

4. **Pectin Separation**

- Used to separate pectin from juice, improving the purity and stability of the juice.

- Suitable for the production of citrus juices.

---

|  |

#### **4. Selection and Maintenance of Decanter Centrifuges**

1. **Selection Considerations**

- Choose the appropriate model based on the type of juice, solid concentration, and processing requirements.

- Consider the material of the equipment (e.g., stainless steel) to handle acidic juices.

2. **Maintenance Recommendations**

- Regularly inspect the wear of the drum and screw conveyor.

- Clean the internal parts of the equipment to prevent clogging.

- Lubricate key components to ensure smooth operation.

---

|  |

#### **5. Future Development Trends**

1. **Intelligentization**

Remote monitoring and fault diagnosis through IoT technology to improve operational efficiency.

2. **Energy Efficiency**

Optimize equipment design to reduce energy consumption and operational costs.

3. **Multifunctionality**

Develop universal equipment suitable for various juice separation scenarios to enhance market competitiveness.

---

|  |

#### **Conclusion**

With its high efficiency, energy-saving, and environmentally friendly features, the decanter centrifuge has become an indispensable device in the field of juice separation. As technology continues to advance, decanter centrifuges will play an even greater role in future juice production, providing strong support for the high-quality development of the juice industry.

---

If you need more detailed technical parameters or case studies, please let me know!

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1