Operating principle

Separation technique of(LW)T series fluid pressurization horizontal solid-bowl scroll-discharge decanter centrifuge:Based on the theory of pre-acceleration separation technology,utilitize rotating kinetic energy convert air negative pressure and fluid pressure into separating energy,reduce feeding resistance and speed up cone point discharge rate.

Gyroscopic-effect design on rotators ensure stability of equipment and stability of fluid matter's running quality within bowl cavity,to increase productivity in unit time. Twice separation structure makes a stable pressure of discharging fluid,and fluid is discharged in reverse direction to tangential line,meanwhile pressurized fluid supplies rotating power to bowl,saves part of energy.

Fluid pressurization separation technique has got following achievements:cylinder of smaller diameter,larger processing capacity,smooth feeding,faster separation,rapid residue discharge

assisted by fluid pressure,no accumulation of residue within cylinder body,drier residue,smaller equipment abrasion,fluid pressure defoaming and lower solid containing rate of clear liquid after separation. This technique could effectively solves following technical defects of existing types of centrifuge:small processing capacity,incomplete separation,hard discharge,material blockage within cylinder body and severe abrasion of assembly parts.

Operating principle

Separation technique of(LW)T series fluid pressurization horizontal solid-bowl scroll-discharge decanter centrifuge:Based on the theory of pre-acceleration separation technology,utilitize rotating kinetic energy convert air negative pressure and fluid pressure into separating energy,reduce feeding resistance and speed up cone point discharge rate.

Gyroscopic-effect design on rotators ensure stability of equipment and stability of fluid matter's running quality within bowl cavity,to increase productivity in unit time. Twice separation structure makes a stable pressure of discharging fluid,and fluid is discharged in reverse direction to tangential line,meanwhile pressurized fluid supplies rotating power to bowl,saves part of energy.

Fluid pressurization separation technique has got following achievements:cylinder of smaller diameter,larger processing capacity,smooth feeding,faster separation,rapid residue discharge

assisted by fluid pressure,no accumulation of residue within cylinder body,drier residue,smaller equipment abrasion,fluid pressure defoaming and lower solid containing rate of clear liquid after separation. This technique could effectively solves following technical defects of existing types of centrifuge:small processing capacity,incomplete separation,hard discharge,material blockage within cylinder body and severe abrasion of assembly parts.

Technical Paramters:

Separation technique

Feeding → Nitrogen protection -> Material acceleration →> Siphon feeding →> Fluid pressure → Separation →> Fluid stabilizer(through gaskets)→ Sediment discharge →> Pressurized liquid discharged with self-priming

pump.

Separation effect factors

centrifuging factor,length to diameter ratio of cavity,air negativepressure,fluid pressurization and fluid homeostasis.

Field control

Bowl rotating speed,rotative speed difference;between;spiral pusher and bowl,depth of liquid pool.Suitable for suspended and viscous materials;larger processing capacity,clearer liquid,drier sediment,smooth sediment

discharge;deceleration separation extends the service life of equipment,energy-saving.

Scope of application

Materials with toxic,volatile,flammable and explosive or produce air foam;occasions with large production and strict requirements to solids and liquids after separation;special materials with a variety of physical properties in mixture.

Application fields

1. Food

A Flesh processing,aquatic products processing and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor,malt and yeast;

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud,industrial effluent, waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes

PVC,polypropylene,polystyrene,synthetic rubber and fiber; E Inorganic chemical industry,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn,cassava and potato;

H Waste liquid recovery and recycling from above industries.

4. Other fields

maceutical intermediates,salts and manures,etc.

Main technical features

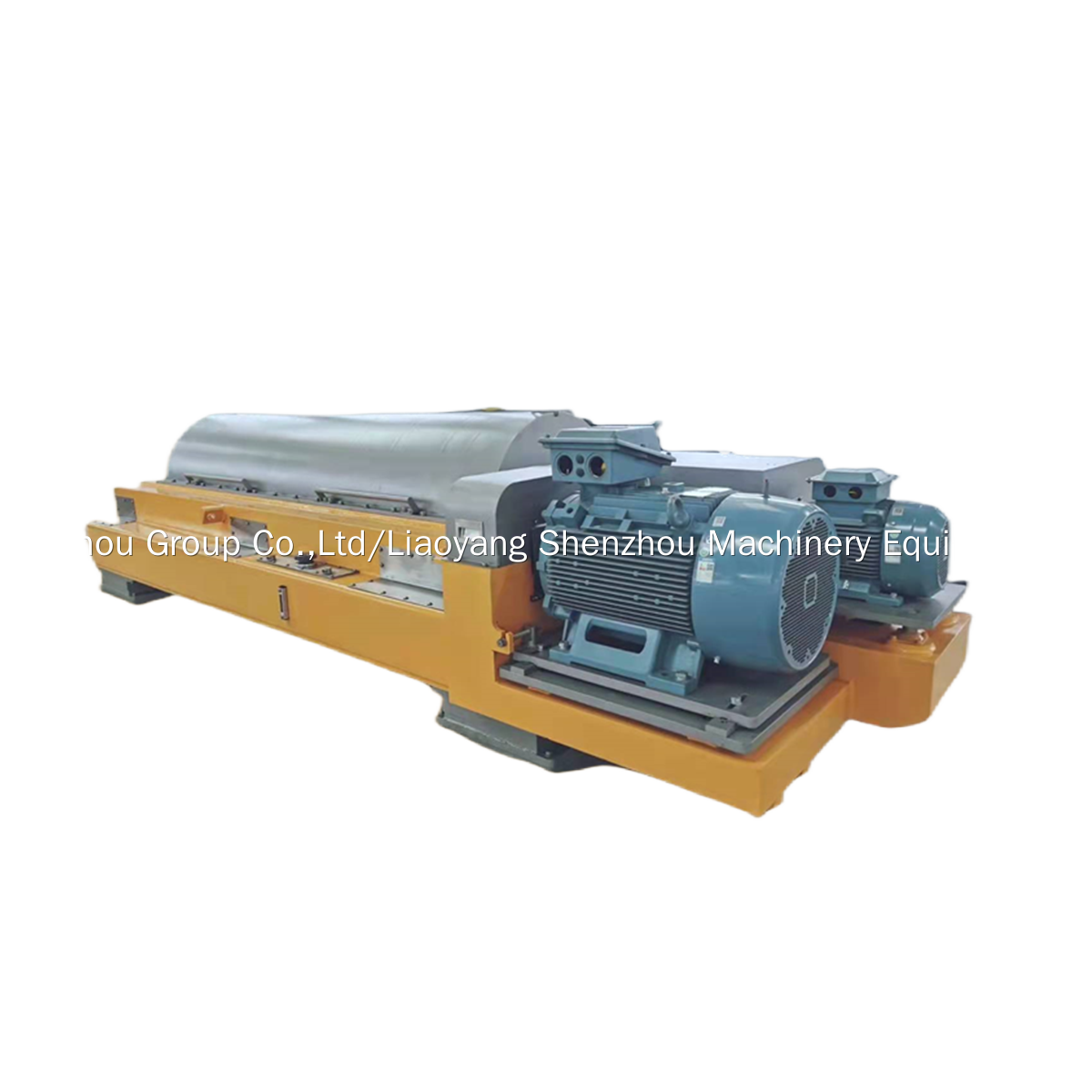

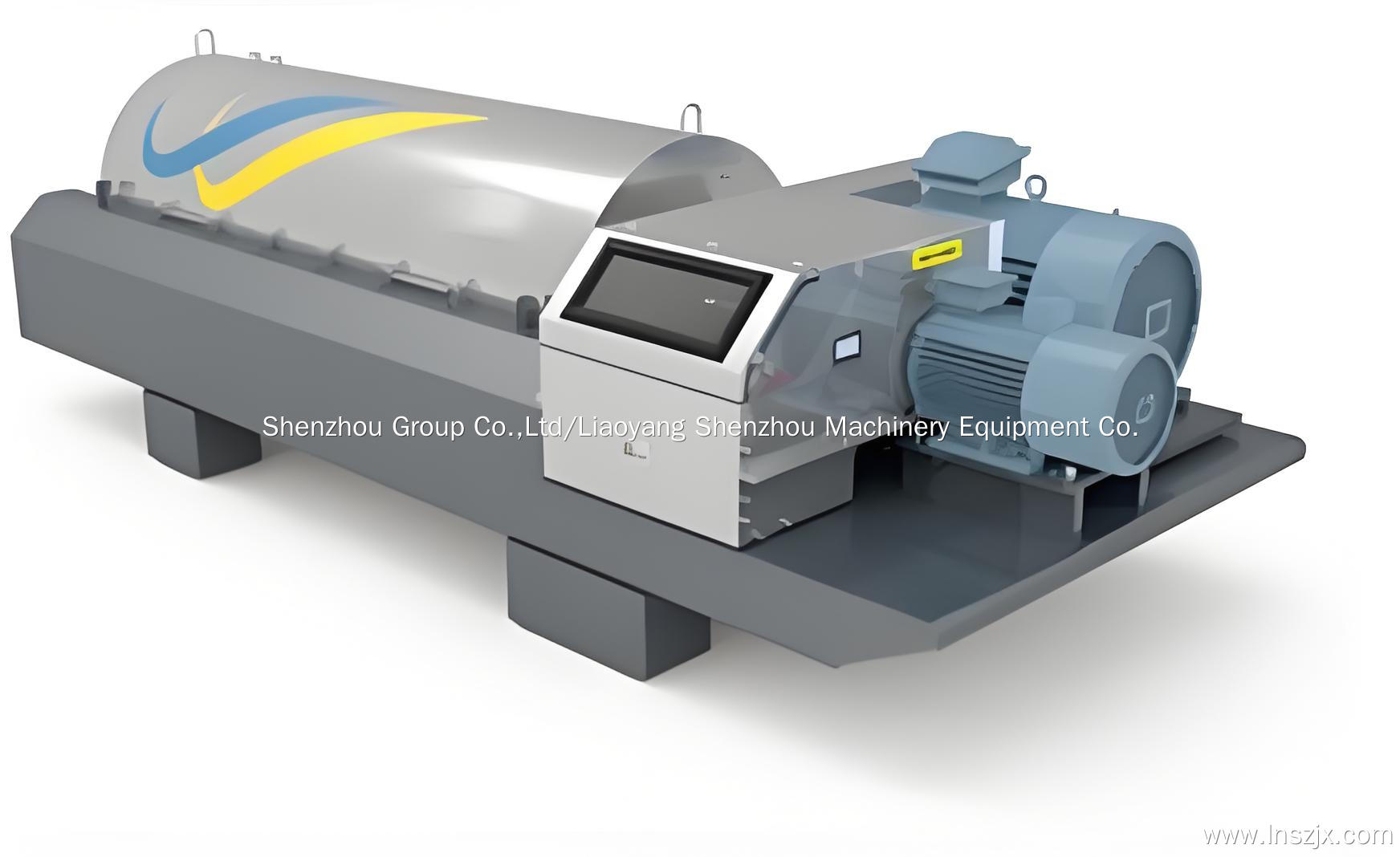

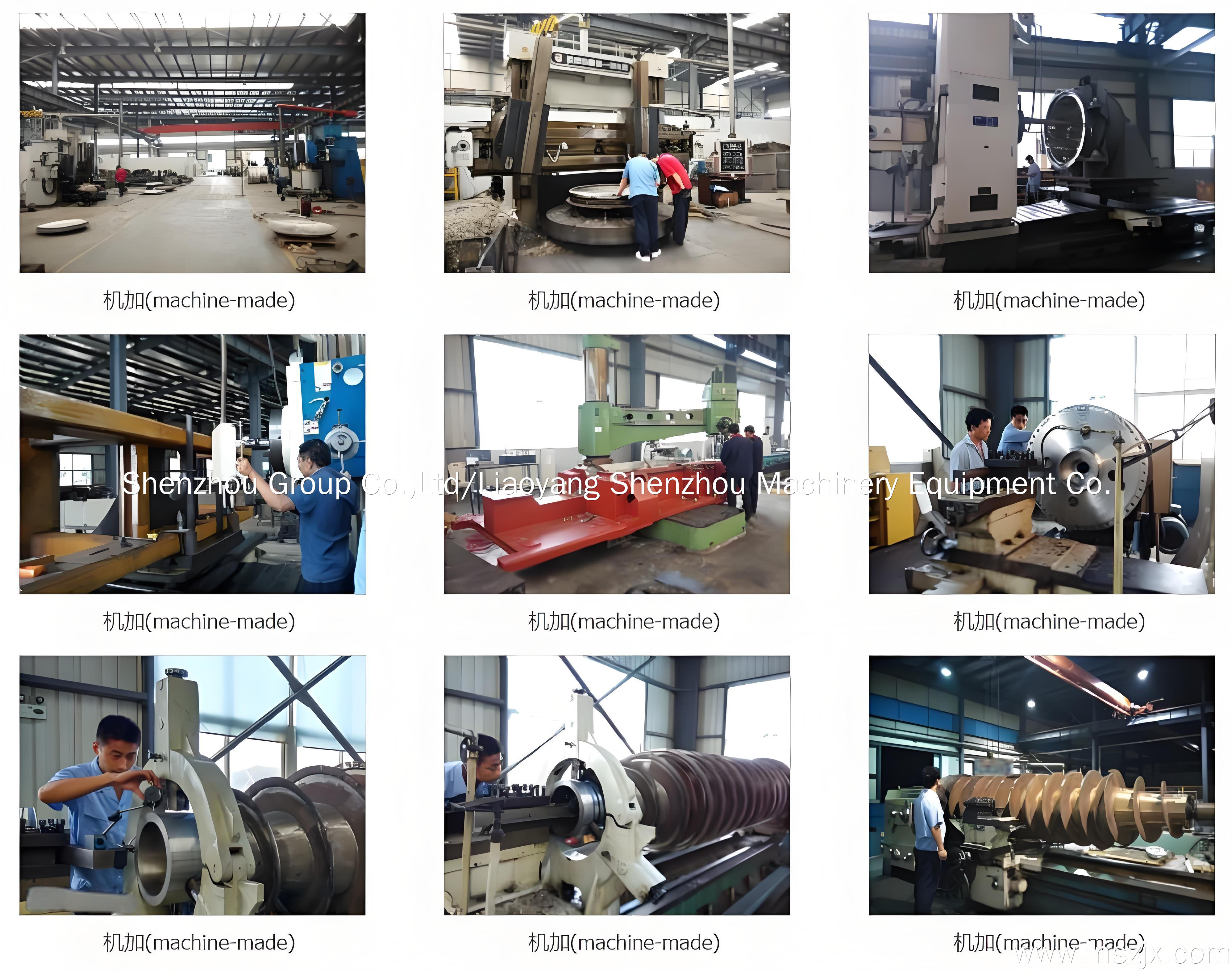

1. Industrial design

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively ease resonance during rotating of bi-rotor When centrifuge works,there is no obvious first-order and two- order resonance regions within designed speed range;meanwhile,whole vibration intensity of bearing seat is definited within 2mm/s ~ 4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly eliminate phenomenon of liquid ring stalling Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW530 and even larger models.lt would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately,our engineers have solved this problem thoroughly.

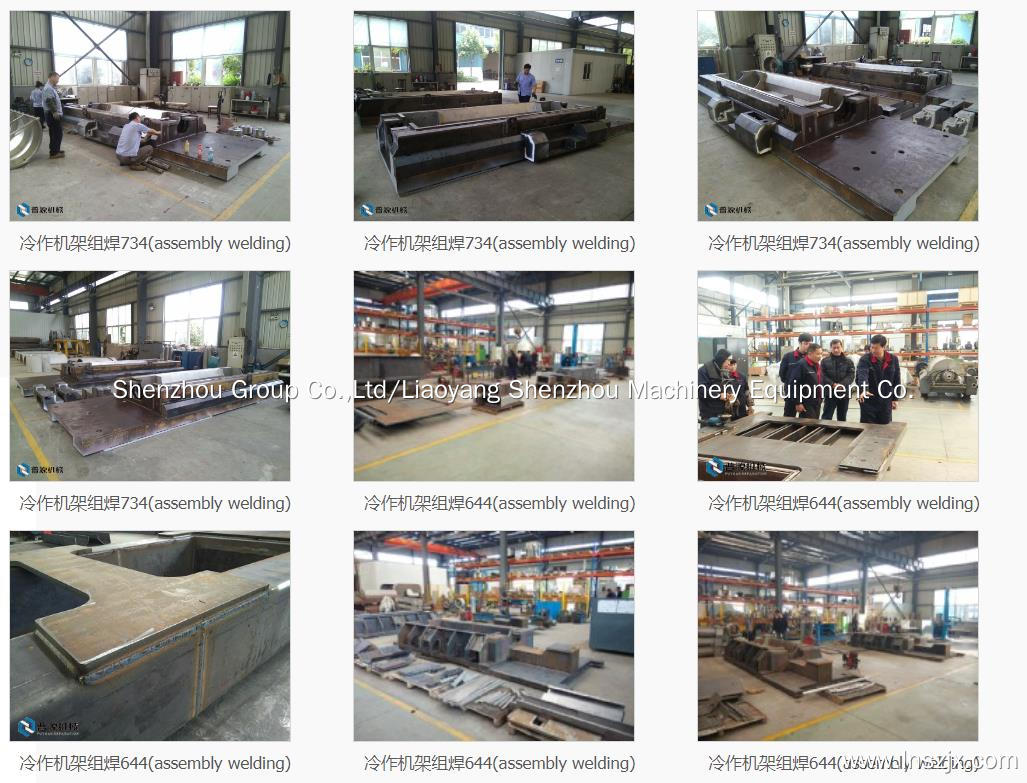

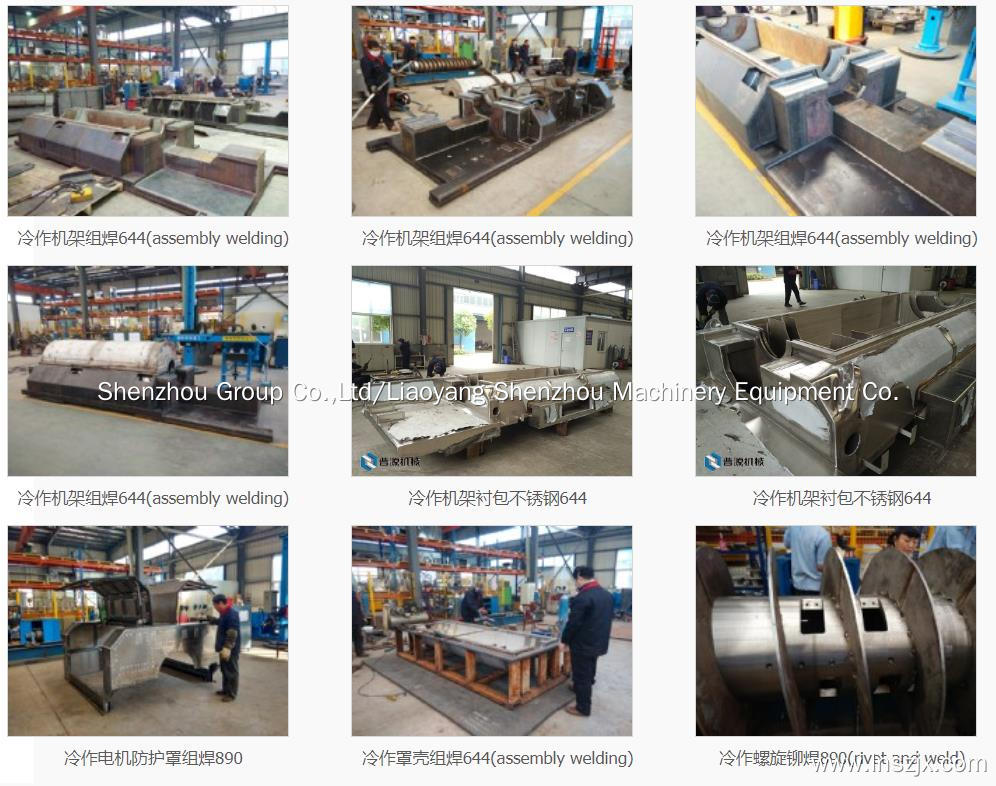

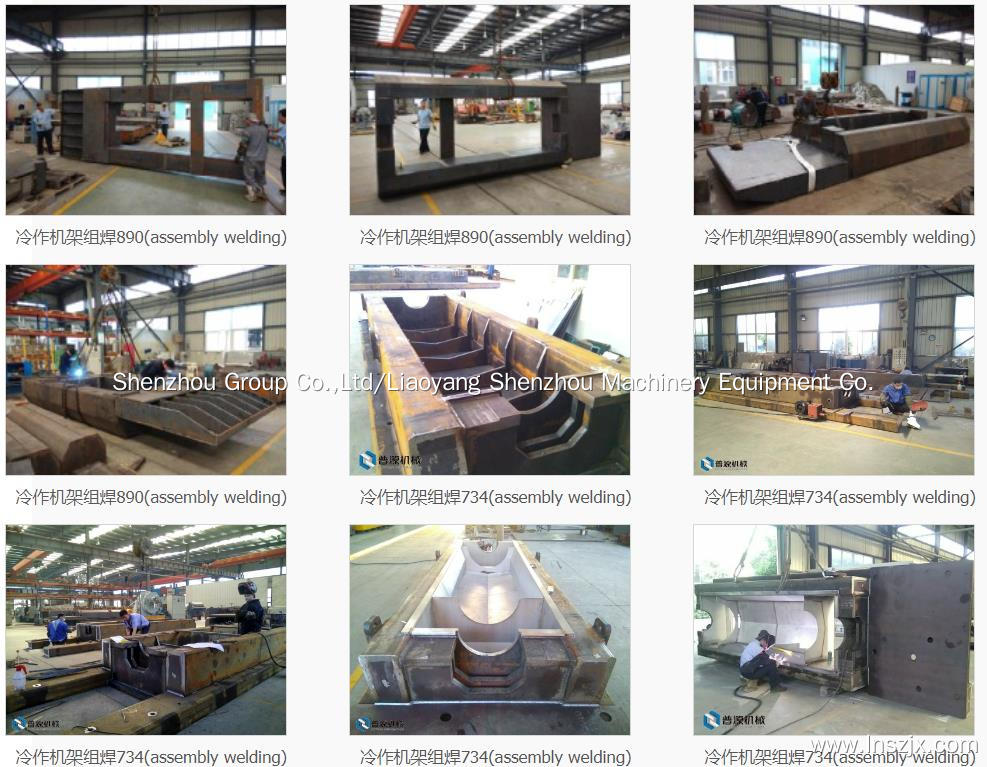

4. Unique technique adopt in main component work-blanks The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main bearing selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

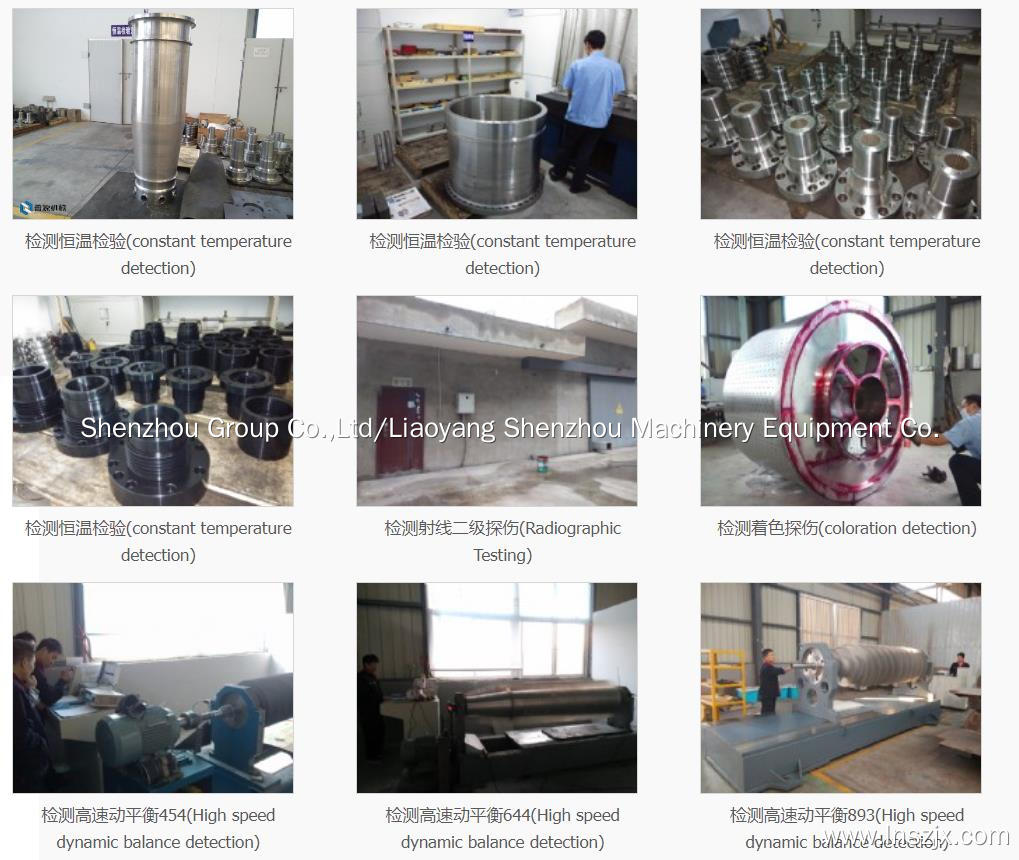

6. Constant temperature detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-changeability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.it is not only easy to maintain,but also greatly improve the reliability and safety of equipment.

8. Simplely and safely in bearing disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high- pressure,during disassemblement bearing from the machine,which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when

disassemble bearing.

9. Main bearing lubrication system

There are two kinds of lubrication systems for specific product models:

A. thin oil lubrication

a.Oil pump offers an uninterruptedly power to ensure oil works circularly;

b.Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

c.Oil filter system ensure lubricant's cleanliness;

d.Oil pressure energy storage system ensure lubrication pump offers an extra oil supply (the pressure is no less than 0.4MPa) for 5 to 6 minutes,when power fails accidentally;

e.Constant temperature system is available.

B. grease lubrication

a.Adopt a grease with properties of extreme pressure resistance,oxidation resistance,abrasion resistance,water scour resistance,corrosion-proof and high temperature resistance.

b.Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main bearing BH device (patent design)

There are two spare safe bearings at either end of main bearing. When machine works well,they keep certain clearance from bearing inside track to chief axis. When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing.Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately,then activates emergency shutdown and goes a smooth shutdown. This system protects machine free from damaging and ensure production safety.

11. GSRL feeding device (potent design)

New design of internal spiral core tube has got following achieves. Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

Advantages: extend separation time of material;achieves operation capacity goes up to 15%~25% accompany with 10%~12% off from maximum rotating speed;reduce solid containing rate in clean liquid;reduce components and assembly units'abrasion.

12. Spiral pusher blades with gradual change spiral lead The design would reduces blades' wear,increase squeezing force on residue at discharge end,to reduce moisture content of residue.

13. HMIl interface

The operating system uses HMl interface,helps to finish all functions of machine and monitor operation state real-time.

14. Intelligent operation & control system Control system uses PLC programmable controller,adopts manual

mode and one-key automatic mode,to operate machine. This system could automatically adjusts and keeps:

constant differential speed between spiral pusher and rotating bowl;constant torque during the spiral pusher's running.lt also has functions of one-key cleaning and one-key standby.

15. Perfect safety protection system

Our products have perfect monitor and alarm system.lt could protects centrifuge on occasions of overloading,shirt circuit or even phase lack.lt would monitor key operating data of centrifuge real- time,such as rotating speed,bearing temperature and whole machine set vibration,etc.lt would stop centrifuge and gives an alarm when the data is abnormal,ensure personnel safety and equipment normal operation.

Selling Point

2.ISO9001 certified: The product is certified in accordance with ISO9001, guaranteeing the machine's quality and safety during operation.

3.Wide range of industry applications: The decanter centrifuge is suitable for various industries, including agriculture, construction, energy, food and beverage, and many more, allowing businesses to choose the most suitable solution for their needs.

4.Expert after-sales service: SENZ provides professional engineers available to service machinery overseas, ensuring a smooth problem-solving process and customer satisfaction.

5.Distribution network across the globe: Showrooms are located across Egypt, Turkey, Italy, Vietnam, and other countries, showcasing the product's extensive presence and allowing potential buyers to inspect the decanter centrifuges locally.

Company Introduction

Shenzhou Machinery, a prominent entity in the realm of industrial centrifuges and centrifugal separators, is based in the esteemed country of China. With a rich tradition of over 50 years and a dedicated pursuit of excellence in manufacturing, our forte lies in crafting state-of-the-art industrial centrifuge machines, and countless other centrifugal separation systems, tailored to our clients' explicit requests.

A veritable beacon of customised industrial machinery, our services are designed for a broad spectrum of demanding interests. The innovative solutions we offer, are particularly prized in the realms of the chemical industry, biology, food production, as well as in various environmental protection projects. We pride ourselves on being proficient in implementing cutting-edge 3D printing technology to realise our clients' boundless creative ideas.

Firmly adhering to rigorous standardisation in our production procedures, Shenzhou Machinery is committed to saving time and resources for both our clients and ourselves, all while striving to bring each and every one of our clients, the maximum levels of efficiency and profitability in their respective domains.

FAQ

who are we?

We are based in Liaoning, China, start from 2018,sell to Southeast Asia(20.00%),South America(15.00%),Eastern Europe(15.00%),North America(10.00%),Eastern Asia(5.00%),Oceania(5.00%),Western Europe(5.00%),Southern Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Mid East(5.00%),Africa(3.00%),South Asia(2.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Biological Machinery & Chemical Machinery, Food & Agricultural Machinery, Environmental Protection & Energy Machinery, Separation & Drying Machinery, Packaging & Filling Machinery

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture centrifuge & separator ,drying & packing machine professional design institute. With rich experience in those machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency: USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

|  |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1