The 2 Phase Centrifuge Tubular Separator offers high performance in separation, with a compact design and easy operation. It is available in GQ and GF models, providing efficient solid-liquid separation for various industries such as biomedicine, food, and chemicals. With a separation factor of 15900~16700xg and the ability to separate particles as small as 0.5μm, this centrifuge is ideal for applications requiring precise separation and clarification.

Our company is a leading manufacturer of high-performance tubular separators, including the advanced 2 Phase Centrifuge. With extensive experience in the industry, we have honed our expertise to deliver superior quality products that meet the most demanding requirements. Our centrifuge is designed to provide efficient separation of liquids from solids, ensuring maximum productivity and cost-effectiveness for our customers. We prioritize innovation and continuous improvement to enhance the performance of our products and exceed customer expectations. Trust in our company for reliable solutions that optimize your operations and elevate your productivity.

Our company is a leading manufacturer of high performance tubular separators, including the 2 Phase Centrifuge. With a strong focus on innovation and quality, we are dedicated to providing cutting-edge solutions to our customers in various industries. Our centrifuge is designed for maximum efficiency and reliability, offering superior performance in separating liquids and solids. We pride ourselves on our commitment to excellence, customer satisfaction, and continuous improvement. Trust in our expertise and experience when it comes to meeting your separation needs with our top-of-the-line products.

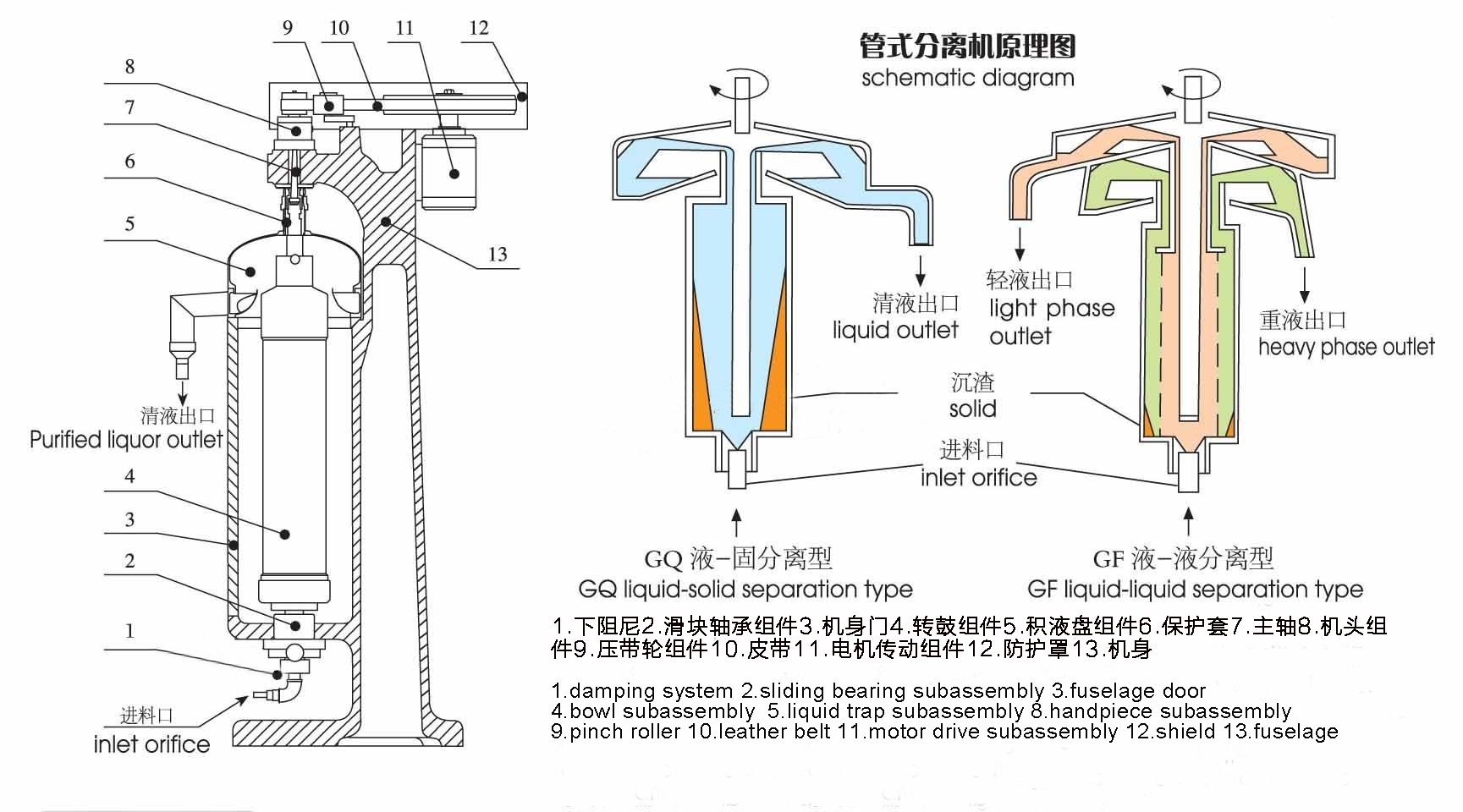

The Feature of Tubular centrifuge

The centrifuge has high performance of separate factor, high capacity, and account for small area and easy to handle, it has t types, one is GQ two phase that can separate solid from the liquid, another is GF series, which can separate the water, solid from the oil.

GF model: Liquid with big density forms the outer liquid circle, while liquid with small density forms the inner circle. Then liquid will flow out of the upper outlet accordingly, and those little solid will be deposited on the drum wall, and be removed by manual after machine stops.

GQ model: Solid particles with big density are gradually deposited on the drum's inner wall, and forms sediment layer, after machine is stopped, is removed by manual. While the clarified liquid flows out through the outlet on the upper of the drum.

Product application

The tubular centrifuge is suitable for solid-liquid separation with small concentration, high viscosity, fine solid phase particles and small difference in solid-liquid gravity. It is mainly used in biomedicine, traditional Chinese medicine preparation, fermentation bacteria liquid separation, health food, beverage, animal and plant. Protein pectin extraction separation, liquid-solid separation of food health products, plant pigments, fine chemicals,ink and other industries. It is an ideal equipment for dynamic continuous separation by centrifugation. The separation factor of high-speed tubular centrifuge is 15900~16700xg, and the diameter of separated small particles is 0.5μm. Therefore, the difference in weight between liquid and solid is small, the solid particle size is fine, the content is low, the medium is corrosive and the materials are extracted and concentrated. Clarification is more applicable.

Blood separation, ink separation, Natural pigment separation, Chemical separation, medicine separation, Escherichia coli separation, Biological vaccine separation, Microalgae separation

Product working principle:

On the top of drum is the flinch axis, under is the damp drift bearing. Main axis linked by buffer and passive wheel,via conveyor belt, fasten wheel, the dynamic is transmit to drum and it will rotate axes to run at rapid speed.

The stuff is ripped into via liquid inlet, under the centrifuge force, the stuff along the wall of drum flow upward.

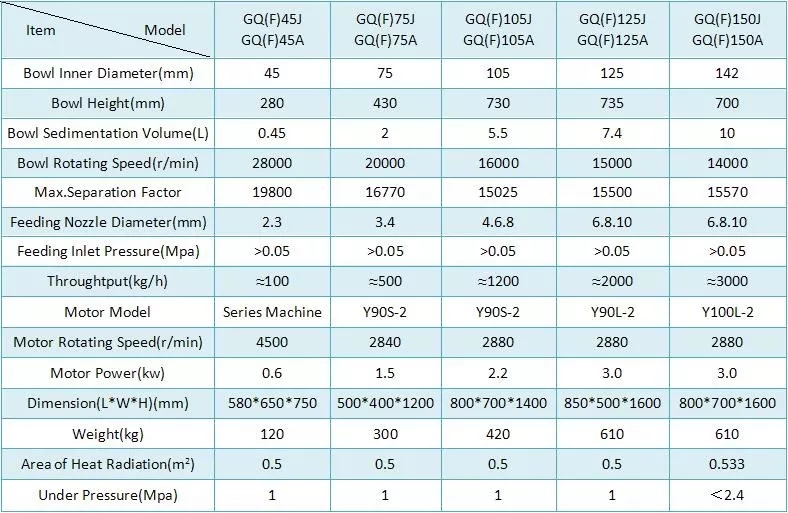

Product Parameters:

Product application case

In essence, a long-standing 2 Phase Centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Regarding the attributes and functionality of the 2 Phase Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the 2 Phase Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1