Our 2 Phase Tubular Centrifuge offers efficient separation of liquids and solids, making it ideal for a variety of industries such as pharmaceuticals, food and beverage, and chemical processing. With its high-speed rotation, it can quickly separate different components based on their densities, resulting in superior purity and yield. Its compact design and easy-to-use controls make it a convenient and versatile solution for your separation needs.

With a rich history of over 20 years in the industry, our company is a leading manufacturer of 2 phase tubular centrifuges that deliver efficient separation solutions. Our team of expert engineers and technicians are dedicated to delivering high-quality products that meet the demanding needs of various industries. Our centrifuges are designed with precision and reliability in mind, providing our customers with optimal performance and long-lasting durability. We take pride in our commitment to innovation and customer satisfaction, ensuring that our products consistently exceed expectations. Choose our centrifuges for unrivaled separation efficiency and trust in our company's proven track record of excellence.

With years of experience in the industry, our company specializes in providing high-quality 2 Phase Tubular Centrifuges for efficient separation processes. Our expert team is dedicated to delivering top-of-the-line products that meet the needs of our customers. We pride ourselves on our commitment to quality, innovation, and customer satisfaction. Our 2 Phase Tubular Centrifuge is designed to provide reliable and effective separation solutions, helping businesses streamline their operations and improve productivity. Trust in our company for all your centrifuge needs and experience the difference in performance and efficiency.

High Speed Tubular Centrifuge

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation.

Product Description

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

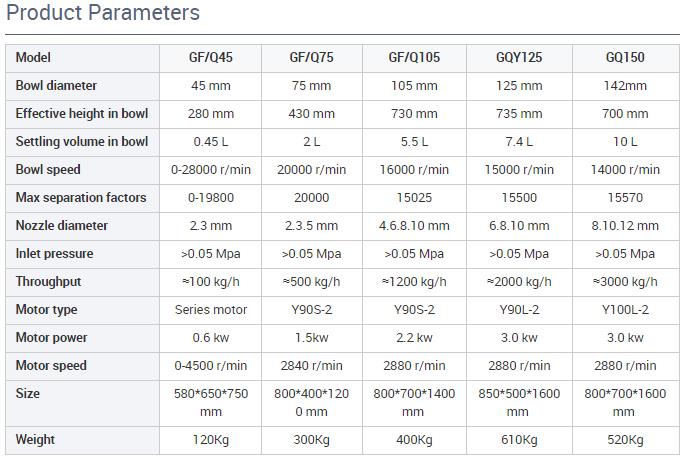

TECHNICAL PARAMETERS OF TUBULAR CENTRIFUGE

HIGH SPEED TUBULAR CENTRIFUGE CLASSIFICATION

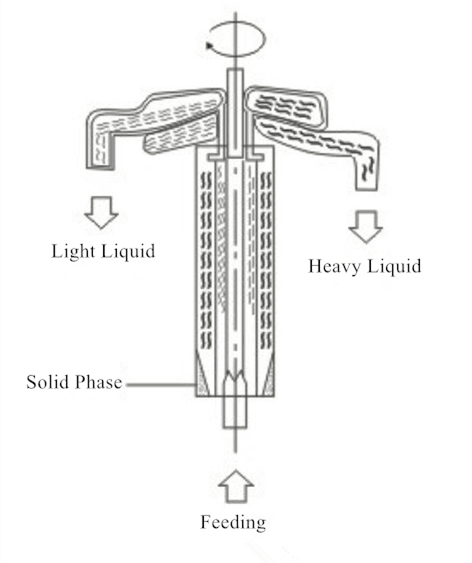

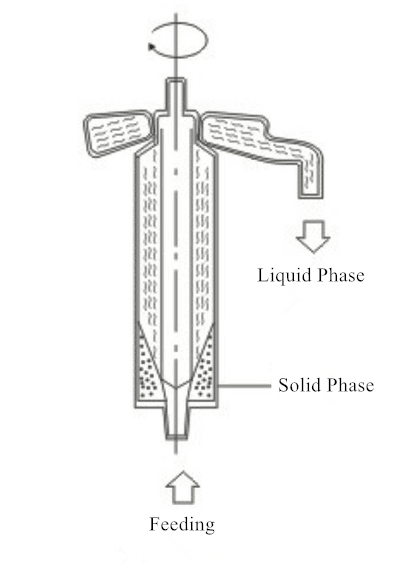

There are two types tubular centrifuge GQ Clarification Tubular Centrifuge (Liquid phase-solid phase) and GF Separation Tubular Centrifuge (Light liquid-heavy liquid-solid phase)

G-Tubular Type Q-Clarification Type G-Tubular type F-Separation Type:Please check the following diagram you will know the difference between GF and GQ tubular centrifuge

The GQ type is mainly used for a variety of difficult-to-separate suspensions in the separation industry, and is especially suitable for the separation of solid-liquid two-phase separations with thin concentration, fine particles and small specific gravity differences.

The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities.

GQ Working Principle:

1. The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted via the control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2. The density of the liquid in the suspension is relatively small, and it spirally rises gradually from bottom to top and then continuously discharges from the clear liquid outlet on the upper part of the rotor;

3.The solid phase is relatively heavier, and it will settle inside the bowl. After the solid is collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, you need to reset the rotor installation, and then start the next separation process.

GF Working Principle

1.The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet;

3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, need to re-install the rotor, and then start the next separation process.

FEATURES OF HIGH SPEED TUBULAR CENTRIFUGE

The enclosure shape is of square shape and round shape.

Stainless steel 304 is used for the surface wrapping of the enclosure.

Stainless steel 316L for the parts in contact with the suspension.

The enclosure body with door-opening design is convenient for disassembly and assembly of the bowl, reduces labor intensity and the separation effect is not affected.

Optional VFD control cabinet, start by inverter, adjustable speed, reduce the starting current and the degree of damage to the transmission components and wear parts, and improve the service life of the equipment and the motor.

The control cabinet is optionally equipped with PLC and touch screen to display the speed and temperature.

According to the field of use, explosion-proof type and cooling type with cooling coil are available.

Mobile integrated base is available.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1