The 3 Phase Centrifuge for Olive Oil Extraction offers a highly efficient and innovative solution for extracting high-quality olive oil. With advanced technology and precision engineering, this product delivers superior performance and maximum yield. Its unique 3-phase separation process ensures optimal extraction results, making it the ideal choice for olive oil producers seeking top-notch quality and production efficiency.

Company Profile:

With a rich history in manufacturing high-quality industrial equipment, our company specializes in producing cutting-edge solutions for olive oil extraction. Our 3 Phase Centrifuge is designed with precision and efficiency in mind, allowing for maximum yield and quality of extracted oil. We pride ourselves on our commitment to innovation and sustainability, always seeking to improve and optimize our products to meet the evolving needs of the industry. Our team of dedicated professionals ensures that every machine is up to our rigorous standards, providing our customers with reliable and durable equipment that exceeds expectations. Experience the difference with our centrifuge and taste the excellence in every drop of oil.

Our company is a leading manufacturer of industrial equipment, specializing in the production of high-quality 3 Phase Centrifuges for Olive Oil Extraction. With a focus on innovation and efficiency, we strive to provide our customers with the best solutions for their extraction needs. Our centrifuges are designed to maximize productivity and ensure top-quality results in olive oil production. Backed by years of experience and a commitment to customer satisfaction, we are dedicated to providing reliable and durable equipment that exceeds industry standards. Trust us for all your centrifuge needs and experience the difference our products can make in your operation.

Product Description

Shenzhou Olive oil disc centrifuge specially used for separate water and impurities from olive oil,get clear oil.More details you can contact us .

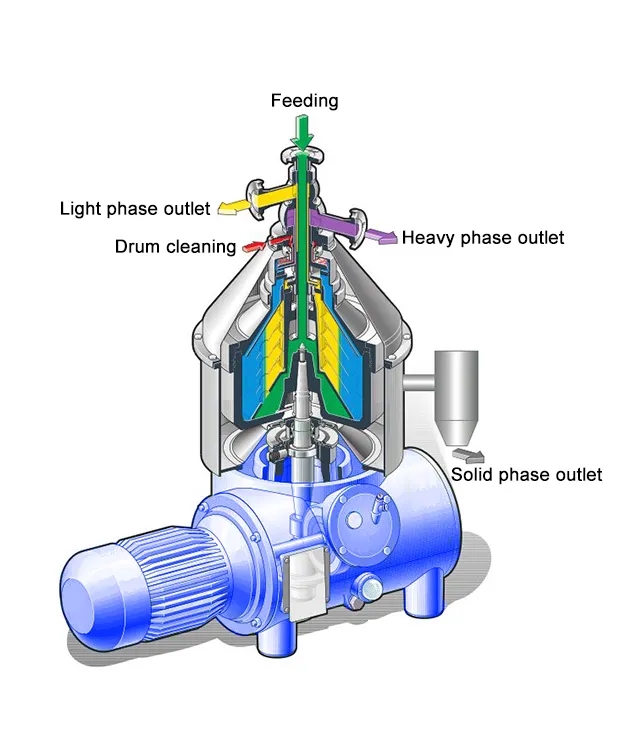

3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation. The 2-phase solid-liquid separation disc separator has only one liquid discharge port and one slag discharge port, while the 3-phase disc separator has two liquid discharge ports and one slag discharge port, which can separate two liquids with different specific gravity at the same time. It can also discharge solid phase materials. Compared with the 3 phase decanter centrifuge, the 3 phase disc separator has larger rotation speed and G force. The 3 phase decanter centrifuge usually has a separation factor of about 3000G, while the 3 phase disc stack separator G force is up to 12000G. Therefore, the 3 phase disc separator can more thoroughly separate liquids with different specific gravity and the liquid phase discharged is more clarified. However, compared to 3 phase decanter centrifuges, 3 phase disc separator is more used to separate materials containing fine particles, with less solids content. So before entering the 3 phase disc separator, the material can separated by the decanter centrifuge for pre-stage separation to reduce the solids content and remove big particles.

Workign principle of shenzhou Olive oil centrifuge:

The separated material enters into the heart of the machine, that is, the inside of the bowl. Under the action of strong centrifugal force, the material passes through a set of disc bundle separation intervals. With the neutral holes of the disc as the interface, the liquid with larger specific gravity moves along the disc wall towards the outside the neutral hole, where heavy slag accumulates in the sediment area, and the heavy phase liquid flows upward to the centripetal pump; the lighter liquid with a smaller specific gravity moves along the disc wall into the neutral hole and converges to the lower centrifugal pump. The light and heavy liquid phases are discharged by the lower centrifugal pump and the upper centripetal pump respectively; the heavy slag is regularly discharged; continuous production is implemented.

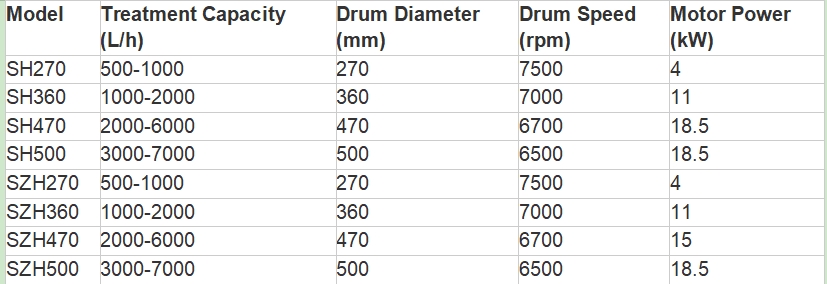

Technical Parameter of Shenzhou Olive oil centrifuge

Olive oil centrifuge separator features:

All parts contacting with the material are made of high-grade stainless steel, which effectively reduces the chemical interaction between the separated material and the surface of the contacting part. The separated light and heavy phase liquid materials are output by two centripetal pumps of different sizes. This machine adopts upper feeding, which has lower inlet pressure on the material. Hydrodynamic coupling and a pair of helical gears or belt drive are used in the power transmission. The speed increase is stable and overload protection can be performed.

The slag discharge action of the sliding piston is automatically controlled by a PLC fully automatic control cabinet specially designed with safety protection devices. It is high level automation, strong adaptability for process adjustment, and convenient adjustment, low noise and good separation effect. Professionally designed centripetal pump system is with stable output pressure, large adjustment range and easy operation.

Application of shenzhou olive oil cenrifuge separator:

Animal and vegetable oil separation:Vegetable oils mainly include: rapeseed oil, cottonseed oil, corn oil, palm oil, soybean oil, peanut oil, sunflower oil, rice bran oil, sesame oil, and safflower oil. Animal oils mainly include: fish oil, and fat purification of various animals.

Beverage industry: dairy purification, separation of milk and cream, fruit juice (orange juice, apple juice, etc.), vegetable juice, tea drinks, coffee, beer and other industries.

Pharmaceutical industry: separation of extracts (such as penicillin, vitamins, E. coli, antibiotics, hormones, etc.), concentration of microorganisms, concentration and clarification of fermentation broth, and separation of blood.

Plant extraction and separation: pigments, peppers, tea leaves, loquat leaves, honeysuckle, ginkgo biloba, salvia, amygdalin, traditional Chinese medicine extraction, etc.

Chemical industry separation: lubricant additives, viscose, PVC, cellulose and derivatives, ink and dye, phosphoric acid, herbicide, latex (synthesis), boiler ash, catalyst, etc.

Fuel and marine oil industry: separation of methyl ester, glycerin, catalyst, soap removal, methanol, water washing methyl ester, extraction of fatty acids, glycerin desalination in the field of bio oil. Recovery and clarification of marine oil, and removal of moisture and mechanical impurities in fuel oil (light diesel, heavy diesel, fuel oil) and lubricating oil of marine diesel engine equipment.

Environmental protection industry: food waste treatment, water treatment industry

Shenzhou Olive oil centrifuge separator package show:

Customers from other countries:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1