This 3 Phase Tubular Centrifuge offers high quality and efficiency at a competitive price, making it a cost-effective solution for various industrial applications. Its advanced design and precise engineering ensure optimal performance and reliable operation. With its compact size and easy maintenance, this centrifuge is a superior choice for businesses looking to streamline their processes and maximize production output.

At our company, we take pride in our commitment to serving our customers with the highest quality products at competitive prices. Our 3 Phase Tubular Centrifuge exemplifies this dedication, offering top-notch performance and reliability. With a focus on efficiency and precision, our centrifuges are designed to meet the needs of various industries and applications. We serve our customers by providing unparalleled customer support, ensuring a seamless purchasing experience from start to finish. Trust in us to deliver the best in centrifuge technology, backed by our unwavering dedication to serving you with excellence.

At our company, we prioritize serving our customers with high-quality products at competitive prices. Our 3 Phase Tubular Centrifuge exemplifies our commitment to excellence, offering top-notch performance and reliability. We understand the importance of providing cost-effective solutions without compromising on quality, and our centrifuge is a testament to that. With its advanced features and efficient operation, we aim to cater to the needs of our diverse clientele, ensuring their satisfaction with every purchase. Trust us to serve you with the best products on the market, backed by our dedication to exceptional service and value.

Product Description

If you want to separate impurities from the milk ,you can choose our GQ tubular centrifuge.If you want to separate cream from milk,you can choose our GF tubular centrifuge.Our tubular centrifuge with high quality and competitive price .

More details check the followings:

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation.

Mo

Mo

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

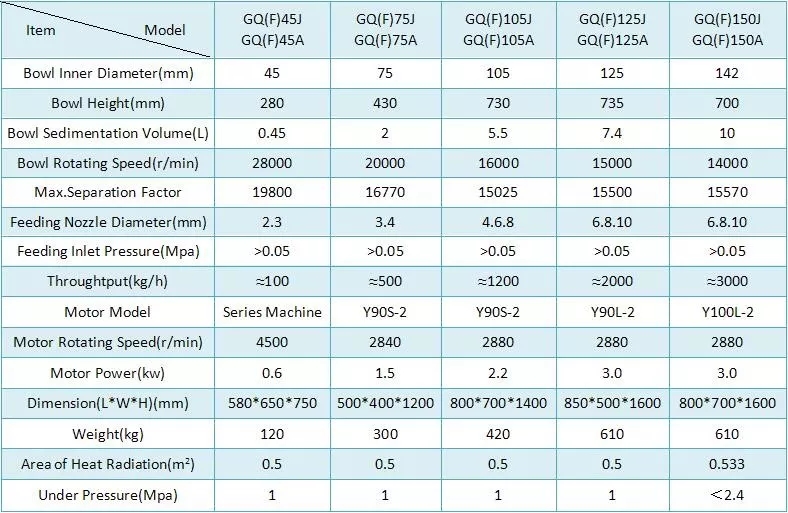

Product technical Paramters:

More details information of GF and GQ tubular centrifuge as followings:

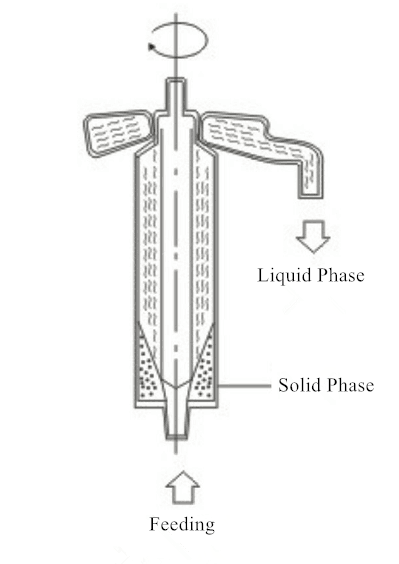

GQ Clarification Tubular Centrifuge (Liquid phase-solid phase):Specially used for solid and liquid separation .The clear liquid from the liquid phase comeout.The solid keep in the drum.

The GQ type is mainly used for a variety of difficult-to-separate suspensions in the separation industry, and is especially suitable for the separation of solid-liquid two-phase separations with thin concentration, fine particles and small specific gravity differences.

GQ Working Principle

1. The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted via the control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2. The density of the liquid in the suspension is relatively small, and it spirally rises gradually from bottom to top and then continuously discharges from the clear liquid outlet on the upper part of the rotor;

3.The solid phase is relatively heavier, and it will settle inside the bowl. After the solid is collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, you need to reset the rotor installation, and then start the next separation process.

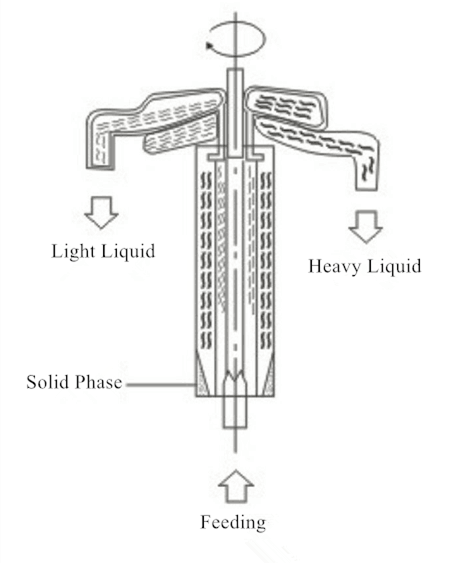

GF Tubular centrifuge more details as following:

There are two outlet in the GF tubular centrifuge,one is for light liquid,one is for heavy liquid .The solid keep in the drum.

GF Separation Tubular Centrifuge(Light liquid-heavy liquid-solid phase),this model specially used for liquid-liquid or liquid-liquid-solid separaiton.More detials as followings:

The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities.

GF Working Principle

1.The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet;

3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, need to re-install the rotor, and then start the next separation process.

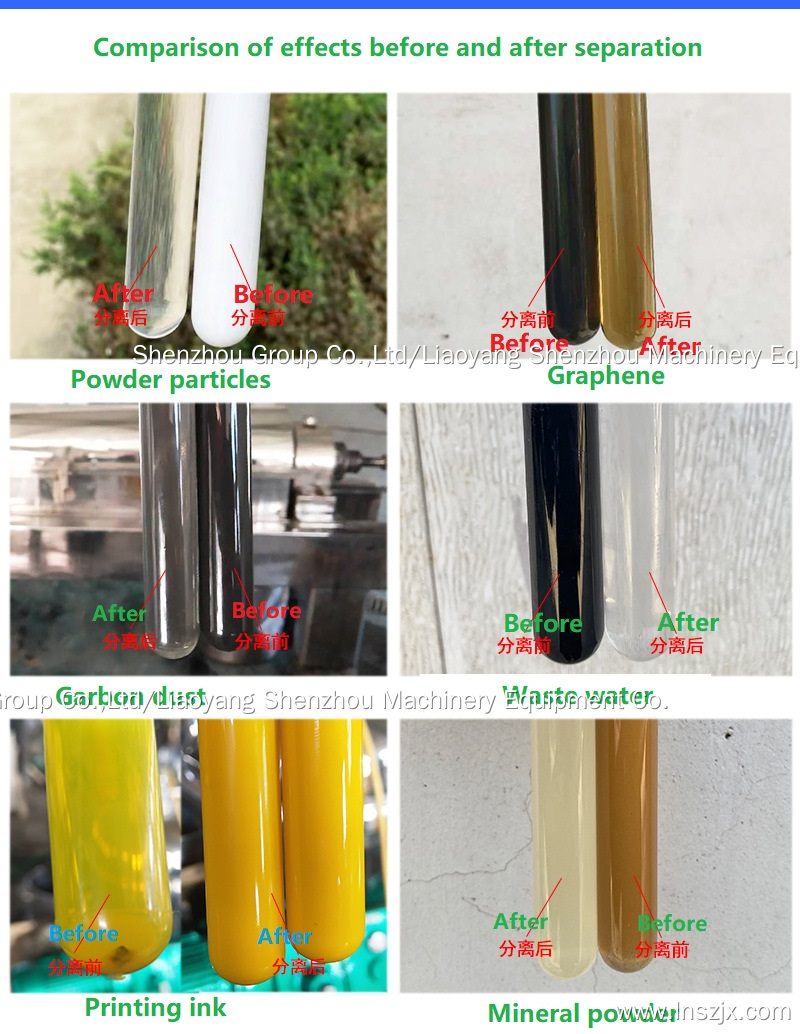

Application and separation effect show:

Our customers:

Package and delivery show:

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Regarding the attributes and functionality of the 3 Phase Tubular Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing 3 Phase Tubular Centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

The buyers of 3 Phase Tubular Centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1