Our 3 Phase Tubular Centrifuge is designed with high speed separation capabilities, efficiently separating liquids and solids with ease. This innovative equipment is crafted with precision engineering and cutting-edge technology for superior performance. Its compact design and user-friendly features make it a must-have for industries requiring fast and efficient separation processes.

Team strength is at the core of our 3 Phase Tubular Centrifuge, high-speed separation equipment. Our team of experts has combined their knowledge and experience to design a product that delivers exceptional results. From engineers to technicians, each member plays a vital role in ensuring top-notch performance and reliability. Our collaborative approach ensures that every aspect of the equipment is optimized for efficiency and effectiveness. With a strong team behind it, our centrifuge can handle the toughest separation tasks with ease, providing customers with a solution they can rely on for their industrial needs.

Team strength is at the core of our 3 Phase Tubular Centrifuge, a high-speed separation equipment designed for efficiency and precision. Our expert team of engineers and technicians work together seamlessly to ensure top-of-the-line performance and durability. With years of experience and a dedication to innovation, our team consistently delivers reliable and cutting-edge solutions for all your separation needs. From initial design to final production, our team's strength lies in our collective knowledge, skill, and commitment to excellence. Trust in our team to provide you with the highest quality centrifuge equipment for your business operations.

Product Description

Regarding the attributes and functionality of the 3 Phase Tubular Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

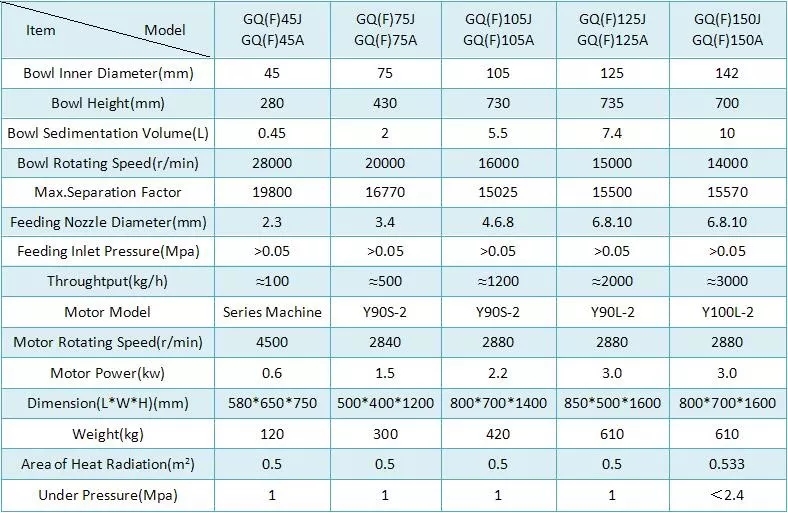

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Plate and frame filter press and an unforgettable experience of partnering with us.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

The buyers of 3 Phase Tubular Centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1