The Avocado Oil Decanter Centrifuge features a horizontal design with a cylindrical-conical solid wall bowl for efficient separation of solid and liquid components. This centrifuge is ideal for avocado oil extraction, with advanced wear resistance for continuous and stable operation, resulting in higher production and better quality oil. The machine is equipped with dual motors, SKF bearings, a PLC touch screen, and a variety of sensors for easy operation and maintenance, making it a reliable and high-performance choice for avocado oil processing.

At our core, we serve quality and innovation with our Avocado Oil Decanter Centrifuge. Designed with a horizontal layout for efficient separation of avocado oil from other substances, this centrifuge ensures optimal performance and results. Additionally, we serve convenience and ease of use, as the decanter is simple to operate and maintain. Our dedication to serving our customers shines through in every aspect of our product, from its durability to its reliability. Trust in our commitment to serve you the best avocado oil decanter centrifuge on the market, delivering exceptional value and performance for your business.

At our company, we are committed to serving our customers with top-of-the-line products like the Avocado Oil Decanter Centrifuge – Horizontal Design. With its innovative design and superior functionality, this centrifuge is perfect for efficiently extracting avocado oil while maintaining its quality. We serve our customers by providing high-quality, reliable products that make their operations run smoother and more efficiently. Our dedication to customer satisfaction means that we go above and beyond to meet your needs and exceed your expectations. Choose us for all your decanter centrifuge needs and experience the difference that quality products and exceptional service can make.

Product Details

Shenzhou--Decanter Centrifuge For Avocado Oil Extraction Process

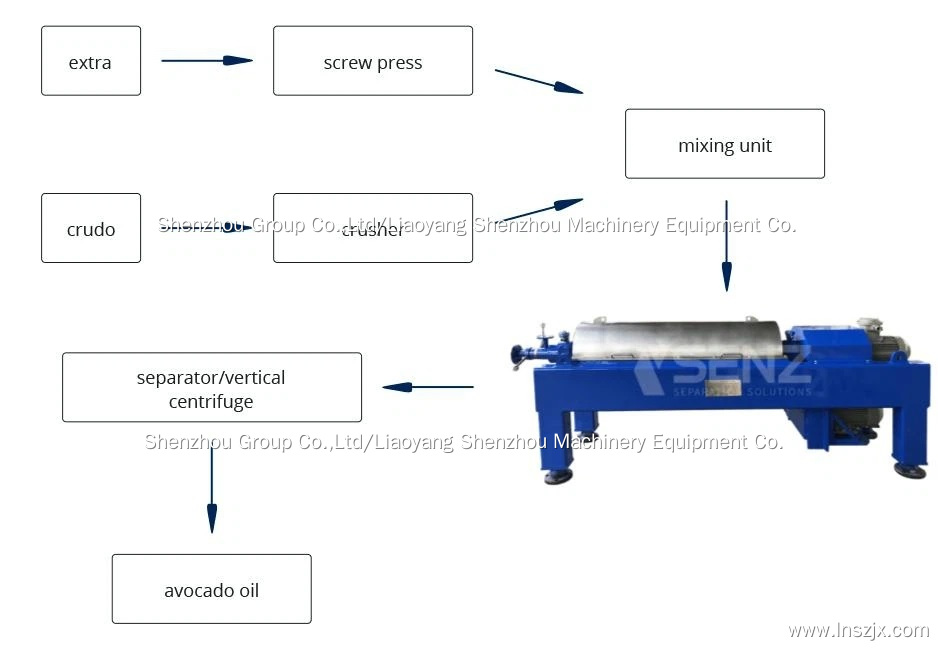

The SHENZHOU decanter centrifuge is ideal for avocado oil production. It efficiently extracts cold-pressed avocado oil by separating pulp, oil, and water from peeled cleaned avocados. The centrifuge's advanced wear resistance allows for continuous and stable operation while refining the oil phase and removing impurities, resulting in higher production and better quality oil.

Configuration

1.Motor: Dual motor and Dual inverter.

2.Bearing is SKF.

3.The PLC touch screen .(Siemens)

4. Run mode: 24 hours continuously.

7. Starting and driving way: inverter

8. Vibration sensors: when the machine have problem. The instrument will automatically alarm and make the machine stop.

9. Quick sensors is can show the running speed.

10. Feeding method: continue feeding.

11. Discharging way: automatic continue discharge.

Material:

1. All the part contacting with the material is ss304.the machine bowl is SS304.

2. Engine base: carbon steel

3. Base on the surface: protective primer and finish for carbon steel.

4. The spiral is used to surfacing hard alloy wear-resistant layer.

5. The bowl exit is cermet.

Product Description

The Avocado oil decanter centrifuge is a horizontal separating decanter with a cylindrical-conical solid wall bowl for the continuous separation of solid and liquid. can continuously feed, separate and discharge at full speed. For some materials that are difficult to separate, in addition to taking corresponding adjustment measures for the separat-ed materials themselves, the centrifuge can also be adjusted and improved accordingly:

1. Increase the length diameter ratio;

2. Adjust the rotating speed of the drum;

3. Adjust the differential speed between the drum and the discharge screw;

4. Change the half cone angle of the drum cone section and adopt multi cone angle sorew;

5. Adjust the overflow radius of the liquid phase outlet;

6.Change the number of screw heads and screw lifting angle of discharge screw;

7. Add BD plate structure;

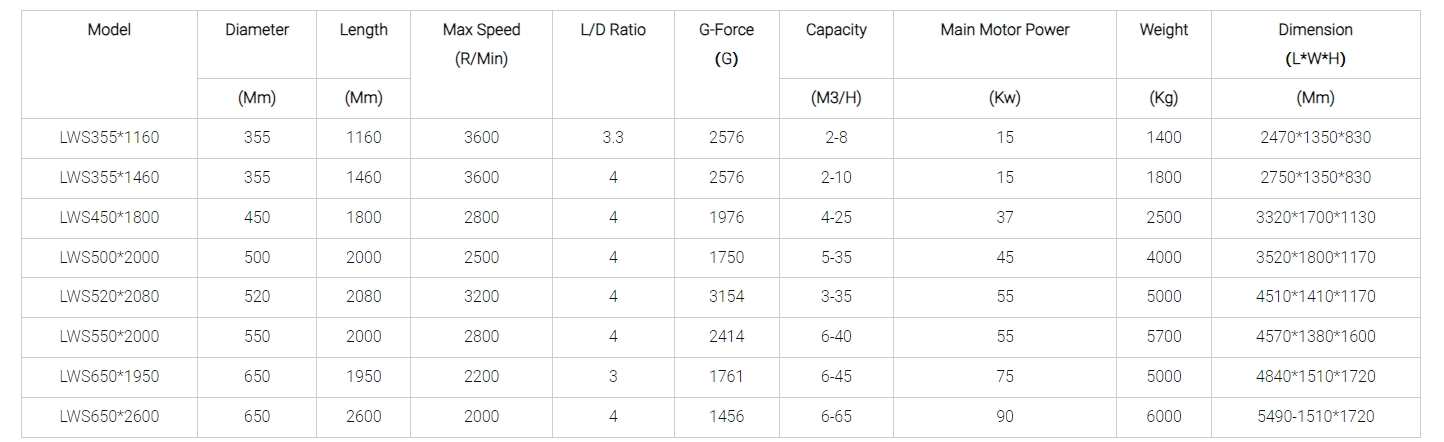

Technical Parameter

Working Principle:

Its working principle is that when the suspension to be separated enters the drum of the centrifuge, the solid particles with higher density than the liquid phase will quickly settle to the inner wall of the drum under the centrifugal force of the drum. The screw conveyor inside the centrifuge pushes the solid phase deposited on the inner wall of the drum to the drying area at the small end of the drum for further dehydration, and then discharged through the slag outlet, and the separated clear liquid will flow out of the overflow weir at the large end of the drum.

Main Technical Features

1. Industrial Design

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively Ease Resonance During Rotating Of Bi-Rotor

When centrifuge works,there is no obvious first-order and two-order resonance regions within designed speed range,meanwhile ,whole vibration intensity of bearing seat is definited within 2mm/s-4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly Eliminate Phenomenon Of Liquid Ring Stalling

Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW550 and even larger models,It would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately ,our engineers have solved this problem thoroughly.

4. Unique Technique Adopt In Main Component Work-Blanks

The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main Bearing Selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

6. Constant Temperature Detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-Change Ability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.It is not only easy to maintain ,but also greatly improve the reliability and safety of equipment.

8. Simplyand Safely In Bearing Disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high-

pressure,during disassemblement bearing from the machine.which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when disassemble bearing.

9.Main Bearing Lubrication System

There are two kinds of lubrication system for specific product models :

A Thin Oil Lubrication

* Oil pump offers an uninterruptedly power to ensure oil works circularly;

* Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

* Oil filter system ensure lubricant’s cleanliness;

* Oil pressure energy storage system ensure lubrication pump offers an extra oil supply(the pressure is no less than 0.4Mpa) for 5-6 minutes,when power fails accidentally;

* Constant temperature system is available.

B Grease Lubrication

* Adopt a grease with properties of extreme pressure resistance ,oxidation resistance ,abrasion resistance,water scour

resistance,corrosion-proof and high temperature resistance.

* Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main Bearing BH Device (Patent Design)

There are two spare safe bearings at either end of main bearing.When machine works well,they keep certain clearance from bearing inside track to chief axis.When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately then activates emergency shutdown and goes a smooth shut down.This system protects machine free from damaging and ensure production safety.

11. GSRL Feeding Device (Potent Design)

New design of internal spiral core tube has got following achieves.Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

Other Application

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental Protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum And Chemical Industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other Fields

Pharmaceutical intermediates,salts and manures,etc.

Customer Photos

Packing & Delivery

FAQ

1.Is Your Price Competitive?

My price is not the lowest in China as for high quality, but we promise for the same quality and collocation,my price is the most favorite,for the same price ,my quality is definitely superior.to other brand.

2.Do You Have OEM Service?Do You Supply The Parts?

Yes,we do,as long as you provide us your drawing and detailed requirements.

3.Do You Have Agent Or Service Center In My Country?

We have some partnership in several countries as Indonesia,Brazil,USA etc,you are warmly welcomed to work as our agent,at this

moment,we have no service centers abroad,but we can provide overseas spot and online technical service in time.

4.How Can We Easily Find Out The Most Fit Centrifuges?

We have experienced engineer team to help you make the model selection,as long as you provide us the detailed processing material

characteristics.

Hot Tags: avocado oil production line decanter, China avocado oil production line decanter manufacturers, suppliers, factory, palm oil decanter centrifuge, dewatering in mineral processing, crude oil decanter centrifuge, oil extraction from sunflower seeds, Used Cooking Oil Separator, decanter centrifuge for sewage treatment plant

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Plate and frame filter press and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the horizontal decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the horizontal decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. horizontal decanter centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1