A three-phase decanter is a centrifugal separator that separates two immiscible liquids while simultaneously separating the solids. The liquid phases discharge through discrete outlets, and the solids eject out of the decanter’s sludge nozzles.

Shenzhou has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product 3 phase centrifuge will bring you a lot of benefits. We are always standby to receive your inquiry. 3 phase centrifuge Shenzhou is a comprehensive manufacturer and supplier of high-quality products and one-stop service. We will, as always, actively provide prompt services such. For more details about our 3 phase centrifuge and other products, just let us know.Our Shenzhou 3 phase centrifuge is manufactured using the finest materials and the advanced equipment.

A three-phase decanter is a centrifugal separator that separates two immiscible liquids while simultaneously separating the solids. The liquid phases discharge through discrete outlets, and the solids eject out of the decanter’s sludge nozzles.

Table of Contents

Working Principle

Types

Process Optimization

Benefits

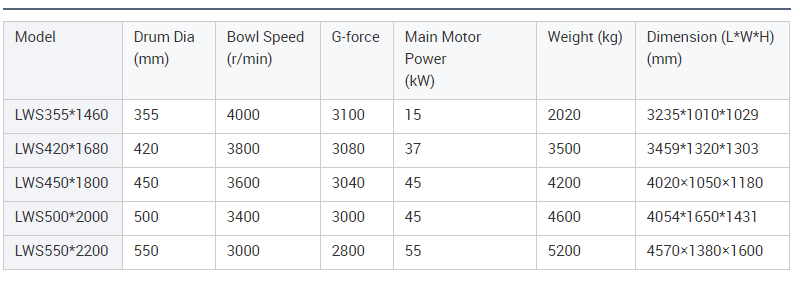

Specifications

Application

Working Principle

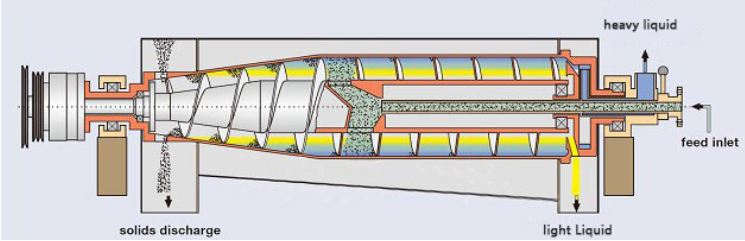

Three Phase Decanter Diagram

The 3-phase separation occurs in the horizontally rotating bowl of the decanter centrifuge. A fixed inlet tube feeds the slurry into the bowl, where the fluids are gently accelerated.

The high centrifugal force causes the heavier solids to accumulate on the bowl wall. The screw conveyor rotates within the bowl at a differential speed to the bowl. The relative rotation between the bowl and the screw pushed the solids to the bowl's conical section.

The centrifugal force drains the liquid from the solids as they move up the conical bowl wall. The conveyor pushes the dry solids through the sludge outlet ports. The ejected solids fall out of the casing vessel.

The entire cylindrical bowl section is the separation surface. The heavy and light liquid phases exit the bowl into individual chambers for each liquid phase in the decanter vessel.

Process Optimization

The three-phase decanter centrifuge can adapt to specific process requirements by:

- Changing the bowl rotational speed to exert the best G-force for separation.

- Adjust the scroll differential rotation to balance liquid clarity and sludge handling capacity.

- Calibrate the pond depth to adjust liquid clarity versus solid dryness.

- Interphase adjustment between the heavy and light liquid phases.

- Changing the feed flow rate. These 3-phase decanters can handle a wide range of feed rates.

Benefits

The benefits of three-phase decanters include:

- The simultaneous separation of two liquids and solids

- The ability to handle a wide range of solids concentrations

- The adjustment of the centrifuge during the process

- Low operating cost for high processing volume

- Compact size to process capacity ratio

- Reduced operator exposure to process fluids by sealed design

- Long service life due to absence of replaceable media

Technical Paramter of three phase decanter from Shenzhou Group you can contact us freely!

Customers from other countries visited Shenzhou Group:

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Chemical&Pharmaceutical Centrifuge and an unforgettable experience of partnering with us.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Regarding the attributes and functionality of the 3 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing 3 phase centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1