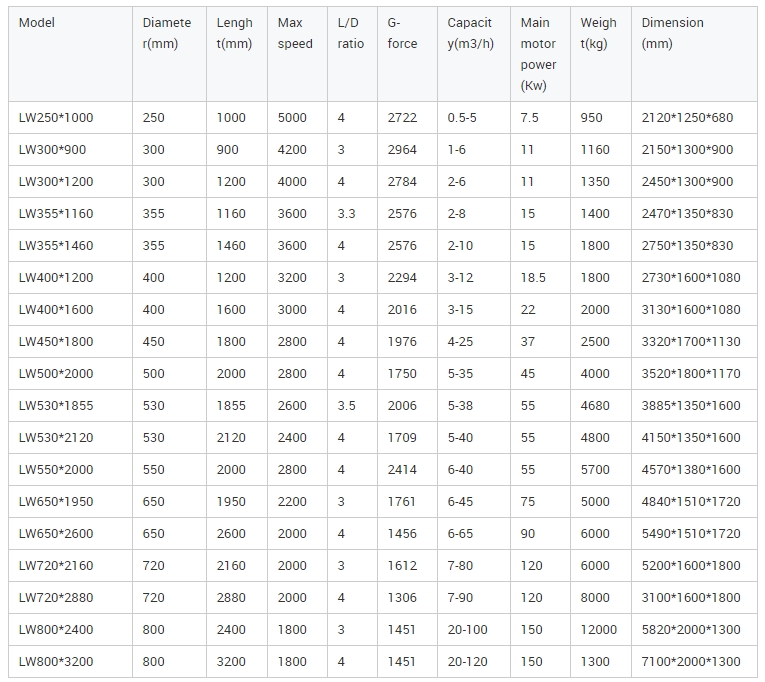

Product Description

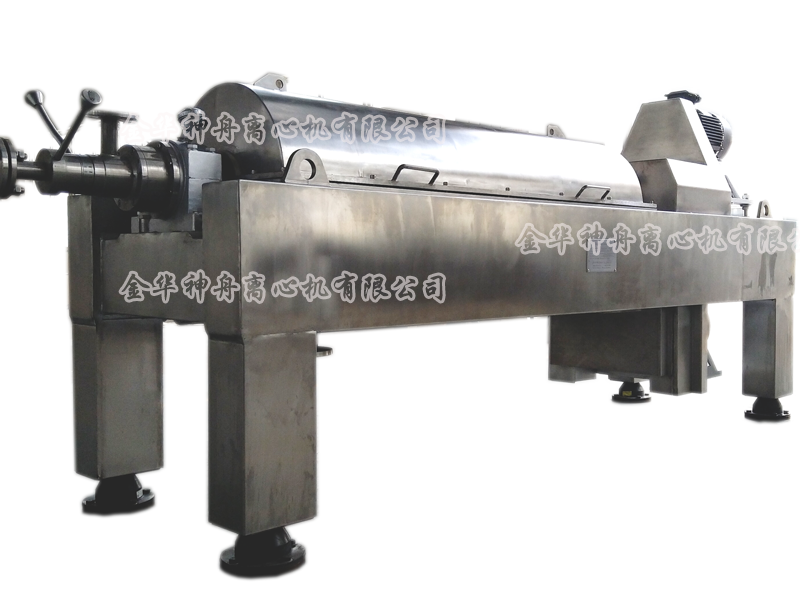

LW series decanter centrifuges usually used dewatering and thickening purpose. It is widely used for maximum dewatering requirements of municipal and industrial wastewater sludge.

The dewatering decanter centrifuge is designed for easy separation material include large particle size, high density difference of solid and liquid, low viscosity, high concentration, high treatment capacity and higher dryness than clarity.The materials like sludge or wastewater containing fine particles usually need to be added with flocculants to gather the fine particles condensed into large ones, and then dewatered with T series decanter centrifuge.

The chemical decanting equipment is designed with a horizontal layout for balanced operation stability and minimal vibration, making it efficient for continuous slurry separation in industries such as chemicals, pharmaceuticals, and mining. Featuring corrosion-resistant stainless steel components and dual electric motor control for precise speed adjustment, this equipment offers exceptional speed limits and separation ratios. With multiple safety protections in place, including over-vibration and overheat protection, this decanter centrifuge ensures safe and reliable operation for a wide range of applications in solid-liquid separation.

At our company, we pride ourselves on serving our customers with top-quality chemical decanting equipment that offers high capacity and efficiency. Our products are designed to streamline the decanting process, saving you time and resources while ensuring precise and accurate results every time. With a focus on durability and reliability, our equipment is built to handle demanding industrial settings with ease. We understand the importance of efficiency in your operations, which is why our decanting equipment is meticulously engineered to meet your needs. Trust us to serve you with the best products for all your decanting requirements.

At our company, we are committed to serving our customers with the best chemical decanting equipment on the market. Our high capacity and efficiency products are designed to streamline your operations and improve productivity. We prioritize quality, reliability, and customer satisfaction in everything we do. From our cutting-edge technology to our top-notch customer service, we are dedicated to meeting your needs and exceeding your expectations. Let us serve you by providing you with the tools you need to succeed in your industry. Choose our chemical decanting equipment and experience the difference we can make for your business.

Introduce

LW Horizontal Decanter Centrifuges feature continuous feeding and discharge. This chemical separation equipment has been applied two-phase (solid - liquid) and three-phase (solid - liquid - liquid) slurries separation industry of chemicals, pharmaceutical, environment protection, as well as mining and food, etc.

Advantage

This liquid clarifying device adopts horizontal design which balances the layout of electric motor and bowl. As a result, outstanding operation stability generates minimized vibration.

Dual electric motor control enables stepless speed adjustment on bowl and spiral components.

Scroll conveyor flight inside this continuous centrifuge is painted by abrasion resistant alloy or welded by hard alloy. Moreover, main components on our horizontal decanter centrifuge, such as rotating bowl and spiral parts, are made from corrosion resistant stainless steel or dual-phase steel, whereby offering exceptional speed limits and separation ratio.

Our mud dewatering equipment comes with three options including cycloidal gear, planetary gear and hydraulic differential, resulting in large rang of differential adjustment. Therefore, this industrial centrifuge can be applible to diverse solids.

Multiple protections are available on our horizontal decanter centrifuge to ensure operation safety, including over-vibratation protection, bearing temperature detection, screw conveyor torque protection rotating and differential speed detection, as well as nitrogen-filled explosion-proof protection, motr overload and over heat protection.

JG type rubber shock absorber requires no anchor bolts.

Main Characteristics

Continuous working, spiral discharging, high capacity.

Compact structure and easy maintenance.

Wide applicability for chemical, oil, foodstuff, pharmacy industries and green industry in which solid-liquid separation is required.

Suitable for various products, capable for separating wide-ranging solid phase grains( 0.005 - 2mm ), especially when separating solid phase has different size grains.

Main Choices

According to user’s requirement, the product contact parts can be made of austenite stainless (321, 316L….), Haynes alloy, titanic alloy or other anti-erosion materials.

Application

Industrial and municipal wastewater treatment

Oil gas drilling mud/fluid control

Washing, separation and dewater of starch

Mycelium and zymotic fluid separation for antibiotic

Dewatering of soybean and wheat protein

Dewatering of fish power and fish meat

Dewatering of vinasse.

Clarification and extraction of fruit juice

Separation and purification for animal and vegetable oil

Production and purification of olive oil, palm oil, avocado oil

Separation and purification for coal tar

Grading of kaolin and graphite

Grading and dewatering of dyestuff and pigment

Froth flotation for cleaned coal and dewatering of coal mud

Grading and dewatering of minerals working principle

Regarding the attributes and functionality of the chemical decanting equipment, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. chemical decanting equipment QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

The buyers of chemical decanting equipment come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1