Shenzhou has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product 2 phase disc Centrifuge will bring you a lot of benefits. We are always standby to receive your inquiry. 2 phase disc Centrifuge We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product 2 phase disc Centrifuge or our company.For , excellent design should be a perfect combination of appearance and performance.

Product Description

Beer Centrifuges do their thing — remove yeast and other solids (like hops) — by spinning the beer around at high speeds, causing denser solids to be spun out of the liquid through gravitational force. Moreover, brewers like centrifuges for removing yeast because the process doesn’t strip away desired hop and malt flavors like pushing beer through filter media can. Additionally, less dissolved oxygen ends up getting introduced into the beer from the process.

A large volume of perfectly brewed beer is lost in the process when cellaring-off dry hop solids, surplus yeast, and trub. It’s all money going down the drain. But with a beer clarifier centrifuge, you can exploit it to the maximum and sell more beer. We have the right solution ready for brewers, small and large!

A beer centrifuge is a self-cleaning disc-stack centrifuge that uses centrifugal force to separate the yeast particles from beer. With a Relative Centrifugal Force (RCF) of over 7,000 Gs, this food-grade centrifuge separates all fine particles down to 0.5 microns to produce clear beer.

Did you know fermentation tank bottoms contain up to 80 percent perfectly brewed beer? And even more, can be recovered from the unclarified hot trub. Why throw it away when you can sell it instead? Get a centrifuge skid, and you can keep all that beer in the brewing process.

Benefits of a Beer Centrifuge

1)、5 to 10 percent more beer from the same amount of raw ingredients.

2)、Same amounts of beer brewed with decisively reduced effort (less energy and hours of work)

3)、Multi-purpose applications in the brewing process to take your business to the next level!

4)、Centrifugal disc clarifiers can be employed in various process stages in wineries. The most common application is for must clarification to remove impurities like broken cells, dirt, soil, pesticide residue, bacteria, fungi, or grape decay.

5)、An industrial food-grade centrifuge is an efficient way to separate the process residue from wine continuously. Exerting over 7,000 Gs, the stainless steel disc-stack centrifuge can remove organic and inorganic particles down to 0.5 microns from fresh wine.

6)、They can also be used to clarify lees in place of costly lees filters to minimize the loss in the production process. The centrifuge process may also be employed in the place of filtration to clarify finished wines. This includes all forms of still and sparkling wines.

7)、Another excellent application for a centrifuge is to spin off yeast and large particles after fermentation or, in many cases, during fermentation to remove yeast and stop the fermentation. This application is perfect for the daunting task of stopping the fermentation of dessert-style wines.

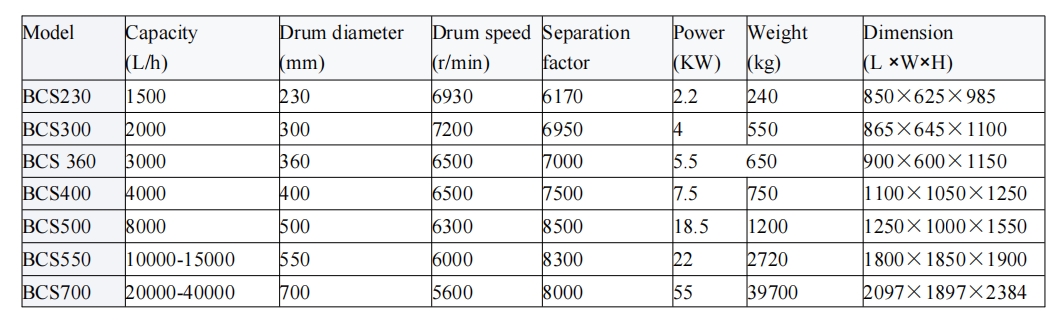

Technical Parameter of beer centrifuge separator

customers from other countries visited Shenzhou Group

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1