After years of solid and rapid development, Shenzhou has grown into one of the most professional and influential enterprises in China. disk bowl centrifuge We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product disk bowl centrifuge or our company.The body of disk bowl centrifuge is made by advanced which is .

Product Description

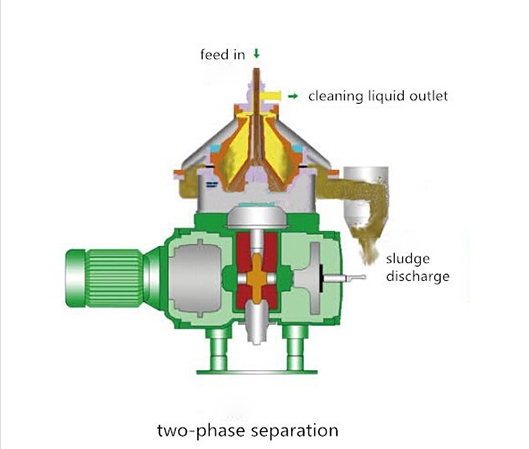

The disc stack separator is also called disc separator. It is a device that rapidly separates solid and liquid through high-speed centrifugal force. The alias is also called disc centrifuge or conical plate centrifuge, which belongs to a type of vertical centrifuge. The disc separator is driven by a motor and rotates at high speed. In the bowl of the disc separator, there is a set of disc-shaped parts nested with each other-commonly known as discs. There is a small gap among the discs, which are used for centrifugal sedimentation of materials. The suspension (or emulsion) to be processed enters the bowl of the disc separator through the feed pipe. When the suspension (or emulsion) flows through the gap between the discs, the solid particles (or droplets) settle on the disc under the action of the centrifuge to form a sediment (or liquid layer). The sludge slides along the surface of the disc to separate from the disc and accumulates in the inner bowl where the diameter is large, and the separated liquid is discharged from the bowl through the liquid outlet. For the 3-phase disc separator, there are two centripetal pumps inside, which can discharge the two immiscible liquid phases having difference densities. The role of the discs in the disc separator is to shorten the settling distance of solid particles (or droplets) and expand the effective settling area of the bowl so as to greatly improve the production capacity of the disc separator. The solids accumulated in the bowl can be discharged through the automatic slag discharge mechanism without stopping the machine. By using the disc separator, solid-liquid-liquid 3-phase separation or solid-liquid separation is realized.

Disc separator applications

1. Biopharmaceutical industry: used in clarification of fermentation broth, separation of vaccines, separation of enzyme preparations, filtration of oral liquids, etc.

2. Vegetable oil industry: widely used in solid-liquid separation of oil crops and oilseeds after pressing; deacidification, degumming and water washing steps in oil refining.

3. Animal oil industry: It is used in the alkali refining of animal fats and oil and water separation steps.

4. Dairy industry: Used for clarification and cream removing of dairy products.

5. Beverage industry: Used for clarification of pressed fruit and vegetable juice, separation of pectin; clarification of coffee; separation of brewer's yeast.

6. Biodiesel industry: Used in the deacidification and degumming of oil and fat raw materials, water washing steps; separation of glycerol and methyl esters.

7. Chemical industry: purification or clarification of chemical raw materials.

This type of separator is a separator for solid, liquid, and liquid separation in the pharmaceutical, beverage, edible oil, chemical, mineral oil and biodiesel industries. There are partial slag discharge, manual slag discharge and full slag discharge for solid discharge. The first type is mainly used for oil refining desalination, and the latter two are used for degumming and dehydration. Both are suitable for liquid-liquid-solid and liquid-solid separation.

It has the advantages of high speed, stable operation, compact structure, small floor space, fully sealed inlet and outlet, low noise, good separation, etc.

Working Principle

The material to be clarified enters the bowl through a feed pipe. In the distribution cabinet of the disc separator, the material is smoothly accelerated until it is synchronized with the speed of the rotary bowl. The disc stack in the rotating cylinder divides the material into many thin layers, forming a large area of clarification area. The high-speed centrifugal force makes the solid slag separated from the liquid in the disc stack deposit into the solid slag collection cavity at the edge of the bowl. The self-discharging 2 phase disc separator can be adjusted according to the material.

Advantage Of disc separator from Shenzhou

1. Fast speed with strong centrifugal force.

2. Relative big bowl design: bigger solid sedimentation area, better separation effect.

3. Smooth working with no pollution.

4. Low noise.

5. Competely sealed.

Main Choices

According to user's requirement, the product contact parts can be made of austenite stainless (304, 316L….), 2205 Duplex stainless steel and other anti-erosion materials.

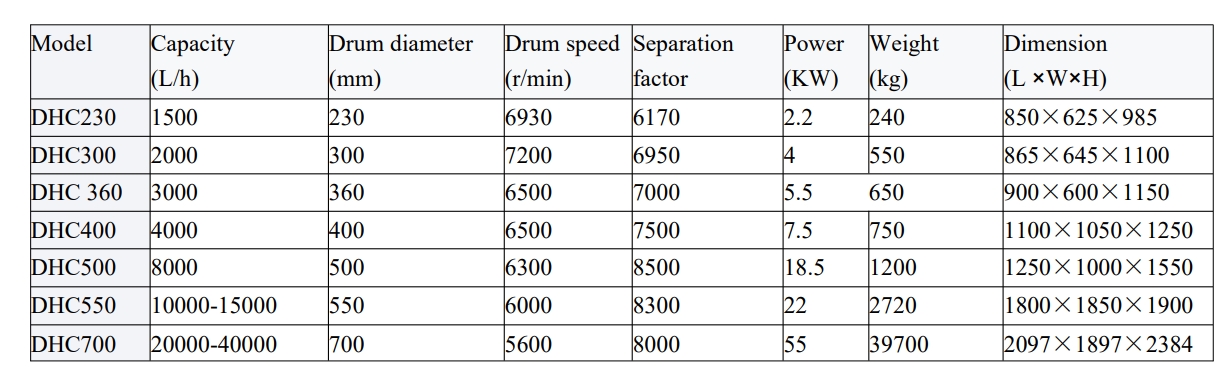

Technical Parameter

Customers from other contries visited Shenzhou Group

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1