The drilling mud centrifuge is designed to efficiently separate components of tank bottom oil, including oil, water, and solids, promoting energy conservation and environmental protection. With a user-friendly design, this centrifuge allows for seamless deployment and operation for the recovery of high-quality oil from tank residues. Additionally, its automatic control system enables continuous and automated operations, reducing personnel-related operating costs.

Team strength is a key aspect of our Drilling Mud Centrifuge for Tank Bottom Oil Recovery. Our team consists of expert engineers, technicians, and support staff who work together seamlessly to deliver top-notch products and services. With years of experience in the industry, our team is skilled in problem-solving, innovation, and customer service. We are committed to providing reliable and efficient solutions for our clients, ensuring maximum productivity and cost-effectiveness. By leveraging our team's collective knowledge and expertise, we guarantee a high-quality product that meets the needs and expectations of our customers. Trust in our team's strength for superior results.

Team strength is one of the core attributes of our Drilling Mud Centrifuge for Tank Bottom Oil Recovery. Our team of experienced engineers and technicians have worked tirelessly to design a high-performance centrifuge that is efficient in separating solids from drilling mud. With their expertise and dedication, we are able to deliver a reliable and cost-effective solution for tank bottom oil recovery. Our team's collaborative efforts ensure that our centrifuge meets the highest standards of quality and performance, providing our customers with a reliable and efficient solution for their oil recovery needs. Trust in our team's strength to deliver exceptional results every time.

Crude oil extracted from wells typically contains water, solids, and various sediments. To separate these components, producers utilize settling tanks, allowing the heavier materials to settle at the bottom. This sedimentation process results in what is known as "tank bottom residue," which often contains a significant amount of high-quality oil. The application of the Shenzhou centrifuge enables the efficient recycling and treatment of this tank bottom sludge. This not only promotes energy conservation and environmental protection but also reduces waste disposal needs by facilitating the recovery of crude oil and the separation of water and solids.

Shenzhou Decanter Centrifuge For Tank Bottom Oil Recovery Process

The Shenzhou 3 phase decanter centrifuges excels not only in effectively separating the components of tank bottoms, including oil, water, and solids but also in facilitating the recovery of high-quality oil from tank residues. Furthermore, our centrifuge features a user-friendly design that allows for seamless deployment and operation even in remote field locations. We offer a comprehensive system of recovery solutions catering to various types of sludge, such as oil refining sludge, aging sludge, and slope sludge. Additionally, it boasts an automatic control system, enabling continuous and automated operations, ultimately reducing personnel-related operating costs.

Shenzhou three-phase oil sludge separation (thermal desorption) system can effectively separate oil, water and solid components in the oily sludge mixture, and the oil content of the residue after treatment is less than 0.3%.

Tank Bottom Oil Recovery Centrifuge Parameter

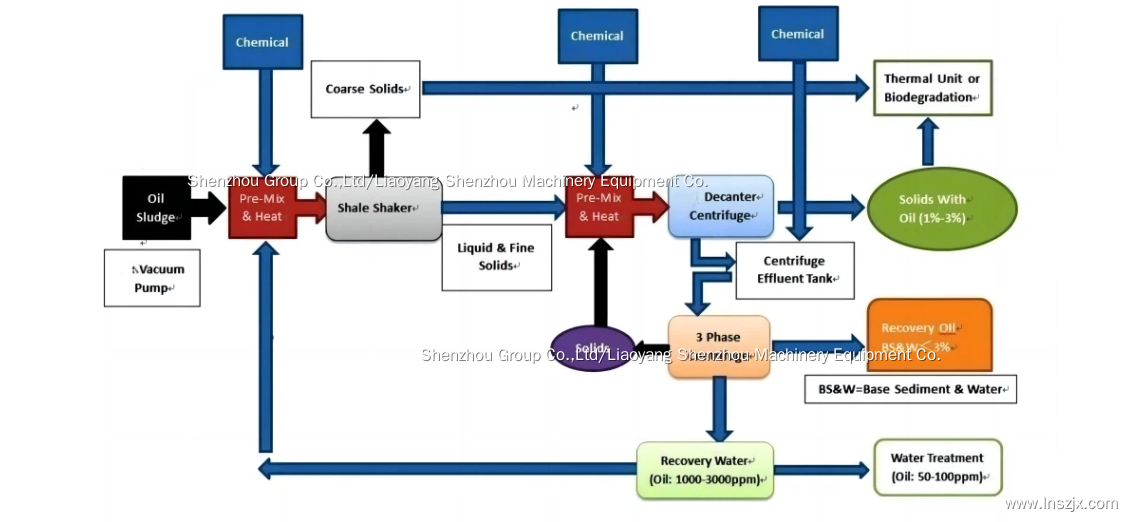

Following the collection and steam heating of Tank Bottom Oil sludge, an appropriate amount of additives, such as demulsifiers and active agents, is introduced to disrupt the emulsified state of the oil-water mixture. After successful demulsification, a high-efficiency LWS series three-phase decanter is employed to continuously separate oil, water, and solids within the oily sludge. The separated water and the non-demulsified oil-water mixture are directed to the sewage treatment system for further processing.Subsequently, an LW series two-phase decanter with high efficiency is utilized for the dehydration process. Any remaining crude oil in the dehydrated solid phase can be recovered through combustion or thermal desorption methods. Following this step, the isolated crude oil undergoes collection and purification through a 3-phase centrifuge separator, resulting in purified oil that can be reused.

Shenzhou Decanters For Tank Bottom Oil Sludge Treatment Process

Tank Bottom Oil, or sludge, develops as a result of sedimentation in oil storage tanks. It occurs due to density differences, allowing impurities, water, and solids to settle at the tank's bottom. Chemical reactions, microbial activity, and temperature fluctuations further contribute to its formation. Tank maintenance and periodic cleaning are essential to manage and remove tank bottom oil, ensuring the integrity and quality of stored oil products.

Oil sludge treatment is a complete set of production process, using the principle of emulsion breaking and centrifugal separation, and the main equipment is composed of dosing system, feeding system, separation system, conveying system, control system, etc.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1