The food-grade three-phase decanter centrifuge for the olive oil industry is a solid bowl decanter centrifuge that offers continuous feeding and discharging. With a high G-force, stainless steel construction, and adjustable bowl speed via VFD, this centrifuge ensures optimal separation of oil, water, and solids. Its automatic operation and high recovery rate of oil make it a cost-effective and efficient solution for olive oil production lines.

Team strength is a critical component in the success of our Food-Grade Three-Phase Decanter Centrifuge for the Olive Oil Industry. Our dedicated team of engineers, technicians, and customer service representatives work together seamlessly to ensure that our product meets the highest standards of quality and performance. With years of experience and expertise in the field, our team is committed to providing reliable and efficient solutions for our customers. By leveraging the collective skills and knowledge of our team members, we are able to continuously improve and innovate, setting us apart in the industry. Trust in our team strength to deliver exceptional results for your olive oil production needs.

Our Food-Grade Three-Phase Decanter Centrifuge is a must-have for the olive oil industry, offering top-of-the-line efficiency and performance. The strength of our team lies in our dedication to quality and precision, ensuring that each centrifuge is expertly crafted and tested for optimal results. With years of experience in the industry, our team of engineers and experts are committed to providing innovative solutions for your olive oil processing needs. Trust in our team's knowledge and expertise to deliver a product that exceeds expectations and enhances your production process.

In order to better purification of olive oil, Shenzhou has specially developed a food-grade olive oil three-phase centrifuge to realize 360 degree automatic feeding and discharging, separation and extraction of olive oil. Meanwhile, it can help enterprises to achieve environmental standards and food safety standards in production.

Product Details

3 Phase Horizontal Tricanter centrifuge

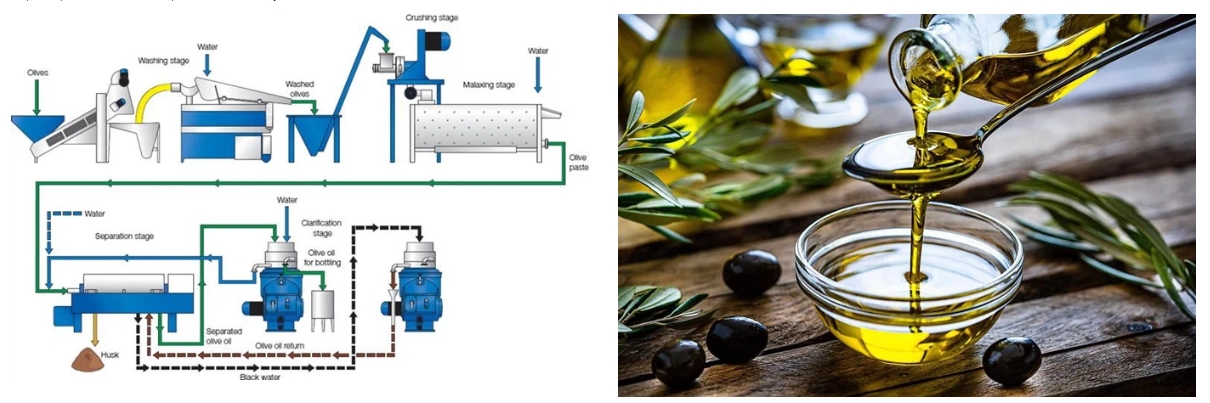

How Does Shenzhou Decanter Centrifuge Work?

The operating principle of a decanter centrifuge is based on separation via centrifugal force. Naturally, a component with a higher density would fall to the bottom of a mixture, while the less dense component would be suspended above it. A decanter centrifuge increases the rate of settling through the use of continuous rotation, producing a g-force equivalent to between 1000 and 4000 G's. This reduces the settling time of the components by a large magnitude, whereby mixtures previously having to take hours to settle can be settled in a matter of seconds using a decanter centrifuge. This form of separation enables more rapid and controllable results.

With a 3 phase decanter centrifuge, it is possible to separate 3 phases from each other in one process step only. e.g. Oilve Oil, two liquids(oil and water) which cannot be mixed because of different densities are separated from a solids phase. The heavy liquid (water) collects in the middle between the oil and the solids layer. Thus the two liquids separated from each other can be drawn off from the decanter. The solids are transported via the scroll to the discharge openings as it happens also in 2-phase separation.

During the extraction of olive oil or palm oil, the plant constituents (seeds, fruits, skins) are pressed and milled. The oil they contain is collected, purified and processed in several processes by means of centrifugal refining and separation technology. Extraction of seed oil or press oil focusses on maximum yield at the same time as careful treatment. Tailor-made Shenzhou decanters and separators help to optimise the overall process decisively.

Technical Parameter

Decanter Configuration

Configuration

1.Motor: Dual motor and Dual inverter.

2.Bearing is SKF/NSK

3.The PLC touch screen (Siemens).

4. Run mode: 24 hours continuously.

7. Starting and driving way: inverter

8. Vibration sensors: when the machine have problem. The instrument will automatically alarm and make the machine stop.

9. Quick sensors is can show the running speed.

10. Feeding method: continue feeding.

11. Discharging way: automatic continue discharge

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

Customer Photos

FAQ

The buyers of solid bowl decanter centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Pusher Centrifuge and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the solid bowl decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. solid bowl decanter centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing solid bowl decanter centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1