The 2 phase centrifuge by Shenzhou is a reliable and efficient equipment for sludge dewatering, featuring high-speed rotation to separate water from sludge effectively. With continuous operation capability, adjustable parameters, and low energy consumption, this centrifuge offers flexibility and cost-saving benefits. Its automatic control system ensures consistent and reliable performance, making it a top choice in industries like chemicals, pharmaceuticals, and environmental protection.

At Graphite Crucible Professional Manufacturer, we pride ourselves on our commitment to serving our customers with high-quality products like the 2 Phase Centrifuge. Our dedication to excellence is reflected in our precision engineering and unmatched reliability. With a focus on delivering superior performance and durability, we strive to exceed customer expectations every step of the way. Our team of experts is here to provide unparalleled support and guidance, ensuring a seamless experience from purchase to operation. Trust in our expertise and let us serve you with the best graphite crucibles on the market.

At our core, we are dedicated to serving our customers with the highest quality graphite crucibles. As a professional manufacturer, we specialize in creating reliable and durable products that meet the needs of various industries. Our 2 Phase Centrifuge graphite crucible is designed to provide efficient and precise results, making it an essential tool for any laboratory or industrial setting. We are committed to serving our customers by offering superior products that deliver exceptional performance and value. Trust us to meet your graphite crucible needs with our top-notch manufacturing expertise and unwavering dedication to customer satisfaction.

Shenzhou is a professional manufacturer of sludge sewadge treatment and solid liquid separation equipment, with more than 40 years of production history. LW horizontal decanter centrifuges feature continuous feeding and discharge, This chemical separation equipment has been applied two-phase (solid - liquid) and three-phase (solid - liquid - liquid), slurries separation industry of chemicals, pharmaceutical, environment protection, as well as mining and food, etc.

Product Description

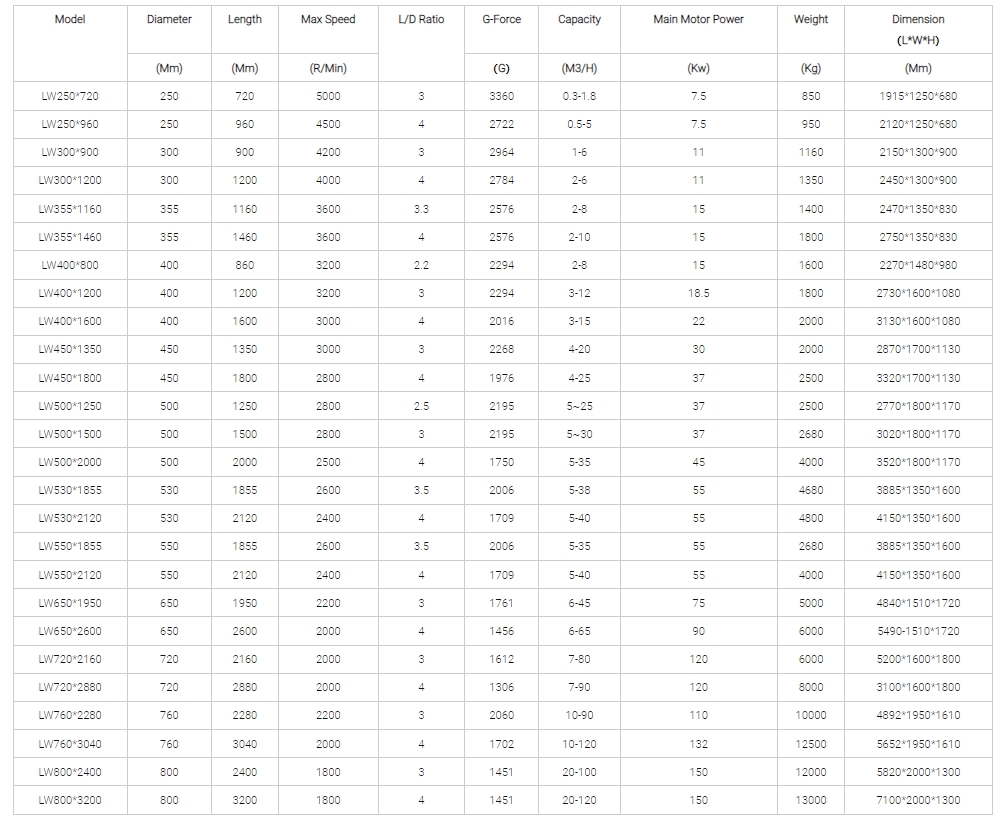

LW sludge decanter centrifuge is the most mature mode for sludge dehydration treatment, It has a high speed of 3600r/min. It has two types of models with different length diameter ratios and different heights. It has the characteristics of medium size, medium speed and medium processing capacity.

In the actual project, it has been used in the following industries: drilling mud, particle classification, magnetic powder, sewage treatment, pharmacy, food, laboratory, petroleum, new energy, biology, chemical fiber, polymeric materials, leather manufacturing, cosmetics, printing and dyeing, knitting, environmental protection technology, etc.

Working Principle

Its working principle is that when the suspension to be separated enters the drum of the centrifuge, the solid particles with higher density than the liquid phase will quickly settle to the inner wall of the drum under the centrifugal force of the drum. The screw conveyor inside the centrifuge pushes the solid phase deposited on the inner wall of the drum to the drying area at the small end of the drum for further dehydration, and then discharged through the slag outlet, and the separated clear liquid will flow out of the overflow weir at the large end of the drum.

Technical Parameter

Product Features

Product Features

1. Efficient Dewatering: The sludge dewatering decanter centrifuge utilizes high-speed rotation to effectively separate water from sludge, resulting in a significant reduction of sludge volume and increased solid content.

2. Continuous Operation: This equipment operates continuously, allowing for a steady and uninterrupted sludge dewatering process, which enhances productivity and efficiency.

3. Adjustable Parameters: The decanter centrifuge offers flexibility with adjustable parameters, enabling operators to optimize the dewatering process based on the specific sludge characteristics and desired outcomes.

4. Low Energy Consumption: Despite its high-speed operation, modern sludge dewatering decanter centrifuges are designed to be energy-efficient, reducing operational costs.

5. Automatic Control: Advanced automation and control systems enable easy operation and monitoring, minimizing the need for manual intervention and ensuring consistent and reliable performance in the dewatering process.

Why Choose Shenzhou Decanter Centrifuge

Production Workshop

Application Cases

Packing & Delivery

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the 2 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Regarding the attributes and functionality of the 2 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 phase centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1