We specialize in the technical development, product testing, manufacturing, sales, and after-sales of disc separators. Our professional team of experts with over 30 years of experience can customize separation solutions for customers in the pharmaceutical, biomedicine, and biochemical industries. We also provide timely and efficient preventive maintenance, troubleshooting, repair, machine refurbishment, and upgrade services.

The 2 phase Centrifuge Separator from SHENZHOU efficiently separates liquid/liquid/solid three-phase and liquid/solid two-phase materials, with the ability to separate particles as small as 2μm. It offers high separation G force up to 14500G for efficiency and stability, meeting GMP and CIP/SIP requirements for the fermentation industry. This separator features rapid processing speed, low energy consumption, compact footprint, and high automation, making it a cost-effective and reliable solution for various applications.

Our company is a leading manufacturer of high efficiency 2 phase Centrifuge Separators, providing innovative solutions for industrial separation processes. With a strong emphasis on research and development, we pride ourselves on delivering cutting-edge technology that offers superior performance and reliability. Our commitment to quality and customer satisfaction sets us apart in the industry, ensuring that our customers receive products that meet their specific needs and exceed their expectations. Trust in our expertise and experience to provide you with the best centrifuge separators on the market, designed to optimize your operations and enhance productivity.

With a strong emphasis on efficiency and innovation, our company specializes in the design and manufacturing of high efficiency 2 phase Centrifuge Separators. We pride ourselves on our dedication to quality and customer satisfaction, offering a product that exceeds industry standards and delivers reliable performance. Our team of experts is committed to continuous improvement and technological advancement, ensuring that our centrifuge separators stand out in terms of both core attributes such as reliability and precision, as well as value attributes such as cost-effectiveness and user-friendly operation. Trust in our company for all your centrifuge separator needs.

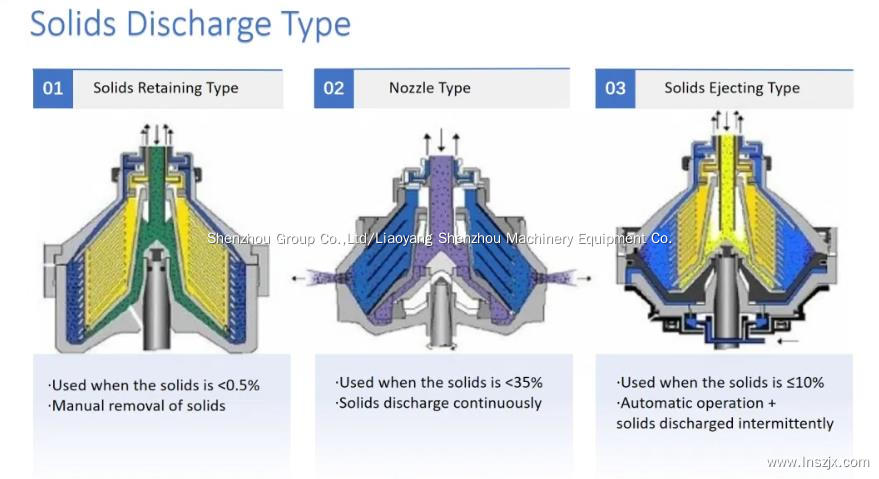

Working Principle of Separator

In the suspended liquid, multiple phase materials with different densities and indissolubilization obtain different sedimentation rates in the centrifugal force field. Based on this principle, rapidly rotating the disc stake can generate a great G force & more great equivalent sedimentation area, which the differential phase materials can be separated in a short time.

Disc Separator Features:

No filter media consumption, eliminating secondary pollution

Continuous and stable operation

Fast processing speed

Effective treatment

Low energy consumption

Moderate capacity

SIP and CIP functions

Compact footprint

Low operating cost

High automation, reliable operation, and low labor intensity

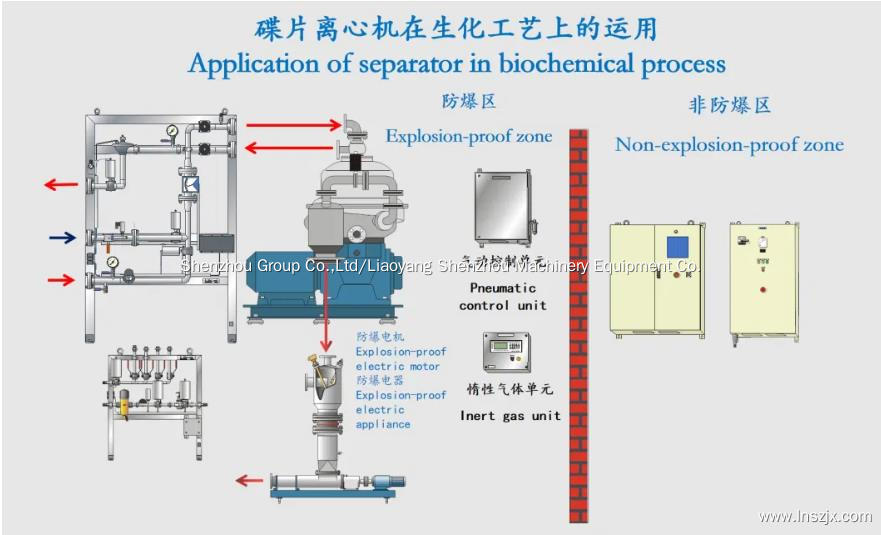

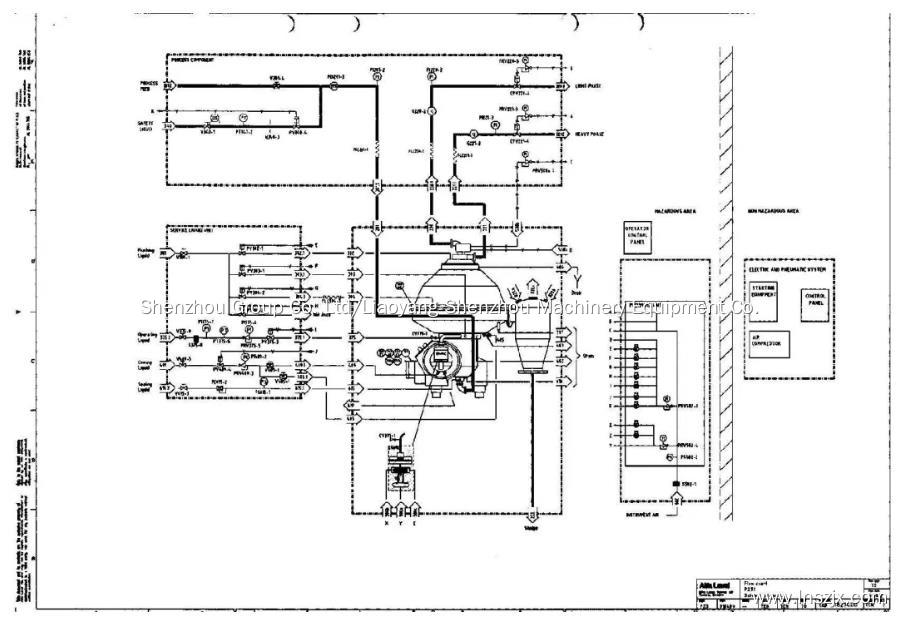

Disc Separator Separation Module System Diagram:

Product Description:

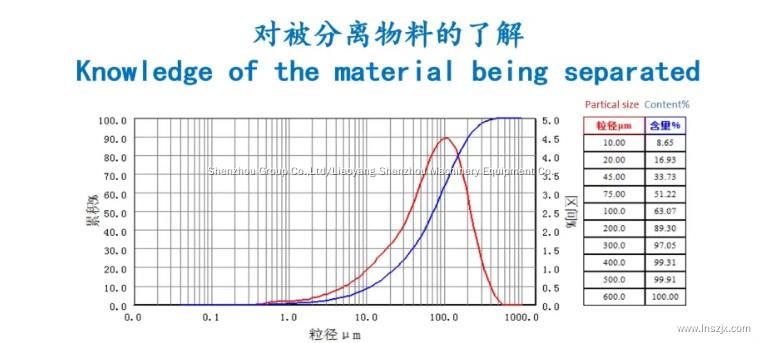

The separator from SHENZHOU

efficiently separates liquid/liquid/solid three-phase and liquid/solid two-phase materials. It can separate non-emulsified liquid particles as small as 2μm and solid particles (including cell debris) smaller than 0.5 microns with a density above 1.02g/ml.

Cell Collection Equipment for Fermentation Industry

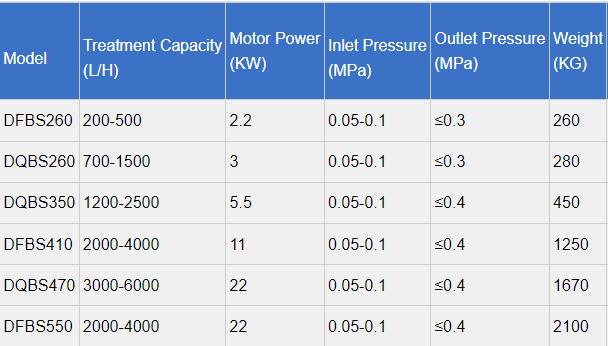

SHENZHOU offers DFBS and DQBS series models specifically designed for the biological fermentation industry. These models are crucial for cell collection, impacting product quality, yield, and downstream processing costs.

Model Features:

Meets GMP and CIP/SIP requirements

High separation G force up to 14500G for efficiency and stability

Customizable design options, including single separator or modular design

Typical Applications:

Concentration and clarification of fermented mash (e.g., escherichia coli, bacillus, probiotics)

Extraction of vitamins, antibiotics, hormones

Collection of microbial cells

Extraction of blood product components

Separation and concentration of yeast

Processing Chinese medicine extracts, pharmaceutical intermediates, synthetic pharmaceutical products

Extraction and separation in genetic engineering

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1