The GQ Tubular Centrifuge offers high efficiency separation with its advanced design and superior manufacturing process. With a top brand reputation in the industry, this centrifuge ensures reliable and consistent performance. Its features include a robust structure, easy operation, and precise separation capabilities, making it the ideal choice for various industrial applications.

With a strong commitment to innovation and quality, our company is a leading manufacturer of high efficiency GQ tubular centrifuges for separation equipment. Our products are designed to provide superior performance and reliability, helping our customers achieve optimal separation processes. With a focus on continuous improvement and customer satisfaction, we strive to deliver innovative solutions that meet the needs of the global marketplace. Our team of experts is dedicated to delivering exceptional products and services to ensure the success of our customers. Trust in our company for high quality separation equipment that will exceed your expectations.

At our company, we are dedicated to providing high-quality separation equipment, such as the High Efficiency GQ Tubular Centrifuge. Our team of experts is committed to ensuring that our products meet the highest standards of efficiency and reliability. With a focus on innovation and superior technology, we strive to offer solutions that enhance our customers' processes and provide long-term benefits. Our company's profile is defined by our dedication to excellence, customer satisfaction, and continuous improvement. Trust us to deliver top-of-the-line separation equipment that exceeds expectations and provides exceptional value for your business.

Product Description

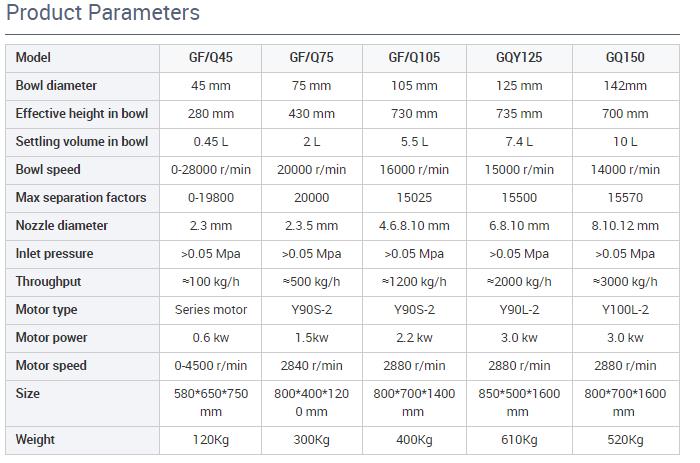

Product Parameters:

Product details:

Customer's workshop show

Our service

FAQ

Regarding the attributes and functionality of the continuous tubular centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Pusher Centrifuge and an unforgettable experience of partnering with us.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. continuous tubular centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the continuous tubular centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1