Description

Decanters with slow rotation speed are normally based on horizontal separation technology. Decanters ensure optimum separation efficiency in the case of suspensions with a very high proportion of solids. They are also used for the extraction of constituents from liquids and for concentrating, dewatering and classifying solids.

Decanter design

Type: 2-phase separation

Material: high quality stainless steel for all wet parts

Bearing: SKF/NSK brand. A special selection and arrangement of bearings provides for long life and exceptional reliability

Wear protection: welded hard facing or spray coating, ceramic technology

This small decanter centrifuge offers high efficiency 2-phase liquid-solid separation, making it suitable for various purposes with outstanding separation effects. Its corrosion-resistant key parts, flexible length-to-diameter ratio, and reliable electrical components ensure wide usage in different fields. With a 12-month guarantee period, abundant spare parts availability, and 24/7 technical consultation, our services prioritize customer satisfaction and machine performance.

At our company, we are dedicated to serving our customers with the highest quality products and exceptional service. Our High Efficiency Small Decanter Centrifuge is designed to provide reliable and efficient separation solutions for various industrial applications. With its advanced technology and compact design, this centrifuge offers superior performance and results. Our team of experts is committed to understanding your unique needs and providing personalized solutions to help you achieve your goals. From product selection to after-sales support, we are here to serve you every step of the way. Trust us to deliver excellence in both product quality and customer service.

At our company, we serve with a commitment to excellence by providing the High Efficiency Small Decanter Centrifuge. Our product showcases top-of-the-line technology and innovation to deliver optimal results in separation and clarification processes. With a strong focus on efficiency and performance, this centrifuge is designed to meet the demands of various industries, ensuring maximum productivity and cost-effectiveness. Our dedication to serving our customers with the best quality equipment sets us apart in the market. Trust us to deliver reliable and high-quality solutions for your decanter centrifuge needs. Experience the difference with our exceptional products and service.

The centrifuge starts and speeds up automatically, when the proper working condition are met and the revolving drum reaches the feeding speed, the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe. After the preliminary speed-up, the susupension passes the outlet of compartment and intro the drum. Because of centrifugal force, the suspension in the drum is quickly devided into tw ophases, the heavier solid phase deposites to the inner wall of the drum, and driven by the differential gear with results in the non-cynchronous movement betwen the spiral feeder and the drum. the solid phase will be transferred into the small end for future dehydration and finally discharged through solid phase outlet. The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Competitive Advantages

2 phase liquid-solid separation

For different purposes

Outstanding separation effect

Wide usage in different fields

Corrosion resistant and resistant key parts

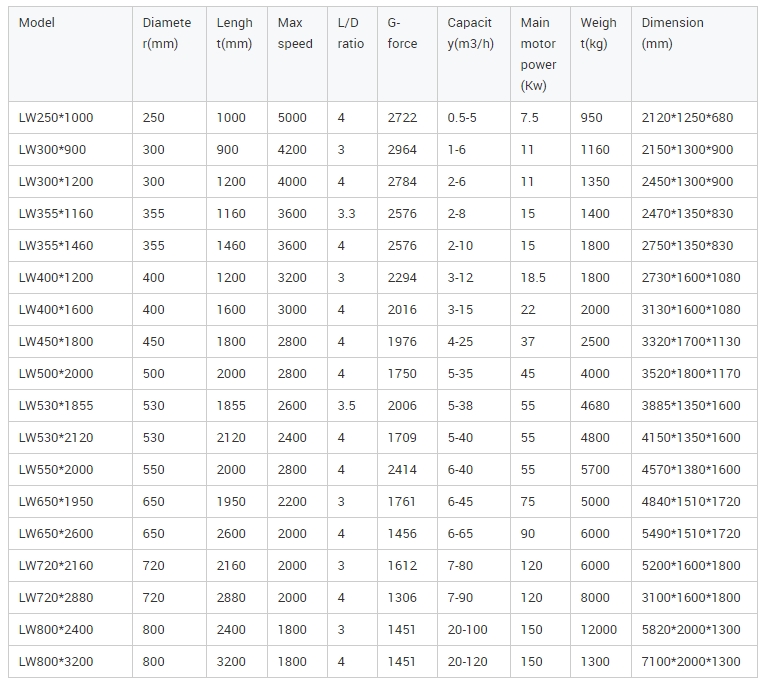

Flexible length-to-diameter ratio

Famous and reliable electrical components

Our services

1. 12 months guarantee period from machine arriving date.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4. 7*24 hours technical consultation.

5. Your workers could get trained both in our factory and yours.

6. Routine tracing till the machine work properly will be done timely.

7. We will remind you to do the normal maintenance.

8. Your suggestions or any comments & reflection would be treated in priority.

9. Marketing team will visit you during our visit in your country if you require.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1