There are two types tubular bowl centrifuge.One type is GQ for solid-liquid separation.One type is GF for liquid-liquid or liquid-liquid-solid separation.

The "Tubular Bowl Centrifuge" is a centrifugal separation equipment with a high separation factor, ideal for solid-liquid separation and liquid-liquid-solid separation in industrial materials. Offering a good separation effect, high output, small footprint, and convenient operation, this centrifuge is particularly suitable for applications with low concentration, high viscosity, fine solid particles, and minimal difference in specific gravity between solid and liquid. With two main series, GF for 3-phase liquid-solid-liquid separation and GQ for 2-phase solid-liquid separation, this versatile equipment features a water jacketed cooling system, adjustable rotating speed, intuitive touch-screen control panel, and robust design for shock-proof operation.

Company Profile:

Our company is dedicated to providing high-quality separation equipment for various industries. With years of experience in centrifuge technology, we have developed the High Efficiency Tubular Bowl Centrifuge to meet the demands of our customers. Our centrifuge is designed to deliver superior performance, ensuring efficient separation of liquids and solids. We take pride in our commitment to innovation and excellence, using cutting-edge technology to deliver reliable and cost-effective solutions. Trust in our expertise and experience to optimize your production processes and achieve maximum results. Experience the difference with our High Efficiency Tubular Bowl Centrifuge.

Our company is a leading provider of high-quality tubular bowl centrifuges, designed for maximum efficiency and performance. With a focus on innovation and reliability, we pride ourselves on delivering top-of-the-line products that exceed industry standards. Our team of experts are dedicated to providing exceptional customer service and support, ensuring that you have the tools you need to succeed. From pharmaceuticals to food and beverage industries, our centrifuges are trusted by customers worldwide for their durability and precision. Choose our centrifuges for exceptional results and superior quality every time. Experience the difference with our company today.

Tubular bowl centrifuge is a kind of centrifugal separation equipment with high separation factor, which is mainly used for solid-liquid separation and liquid-liquid-solid separation of industrial materials. Tubular bowl centrifuge has good separation effect, high output, small footprint and convenient operation. It is especially suitable for solid-liquid separation with low concentration, high viscosity, fine solid particles and small difference in specific gravity between solid and liquid.

There are two main series of tubular bowl centrifuge, GF and GQ. GF is 3-phase for liquid-solid-liquid separation; GQ is 2-phase for solid-liquid separation.

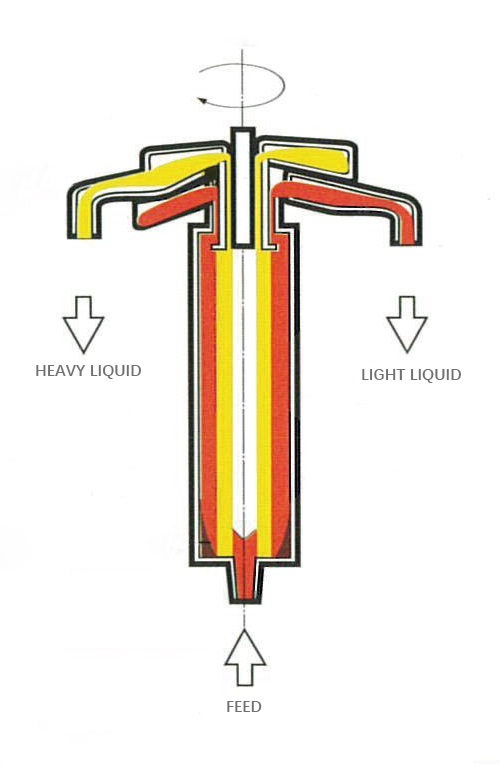

GF Tubular Bowl Centrifuge Working principle: The motor transmits the power to the driven wheel through the transmission belt and the tension wheel, so that the bowl rotates around its own axis at high speed, forming a strong centrifugal force field. The material enters the drum from the liquid inlet at the bottom. Under the action of the centrifuge, the liquid phase with high density forms an outer ring, and the liquid phase with a low density forms an inner ring, and flows to the respective liquid outlets on the upper part of the bowl to be discharged. Trace solids It is deposited on the wall of the bowl and is manually discharged after the machine is shut down.

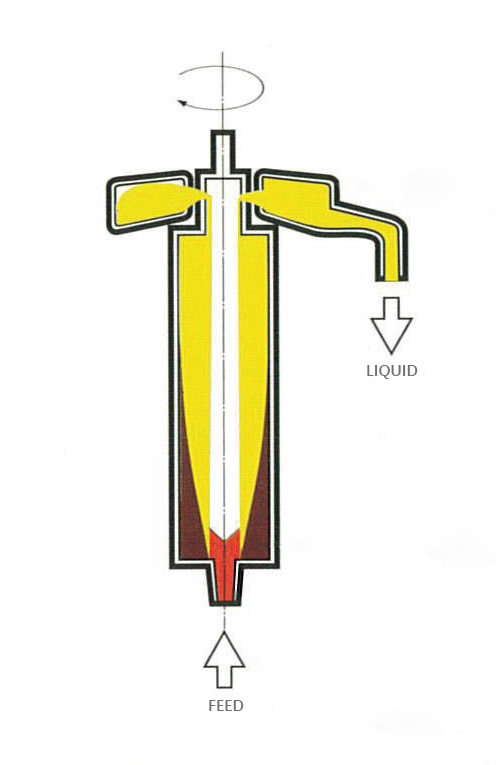

GF Type Show GQ Type Show

GQ Tubular Bowl Centrifuge working principle: it is composed of body, transmission device, bowl, and liquid-inlet bearing seat of the liquid collection plate. The upper part of the bowl is a flexible main shaft, and the lower part is a damping floating bearing. Through the transmission belt, the tension pulley transmits the power to the passive pulley, so that the bowl rotates around its own axis at high speed, forming a strong centrifugal force field, and the material enters from the liquid inlet at the bottom. Under the action of centrifugal force, the solid phase particles in the liquid phase Since the density is greater than that of the liquid phase, it gradually moves to the inner wall of the bowl to form a sediment layer, and the clarified liquid is discharged from the upper discharge port. When the thickness of the sediment layer affects the clarity of the liquid phase, or reaches the rated slag capacity of the bowl, manually remove the sediment on the bowl wall after shutdown.

Features

Ultra-High separation factor

Continuous processing

Two phase (liquid/solid) separation

Three phase (liquid/solids/liquid) separation

High recovery of sludge

Water jacketed cooling system (optional)

Rotate speed adjustable (optional)

Intuitive touch-screen control panel

Robust design and shock proof operation

Applications

– Pharmaceutical

Collection of pharmaceutical intermediates, herb extracts, plant fibers and chlorella

– Food processing

Soy bean, fat, vegetable oil, starches, grains, gelatin, amino acids, soy sauce, reducing fat in milk

– Waste water treatment

Cleaning on straining waste water, leather waste water, petroleum tank sludge, waste oil

– Chemistry industry

Cleaning and collection of ink, paints, ammonia, barium, aluminum, zinc, activated charcoal and stainings

– The other fields

Milk fat processing, cosmetics, cod-liver oil, yeast processing, and many other separations of solution and collection of solids

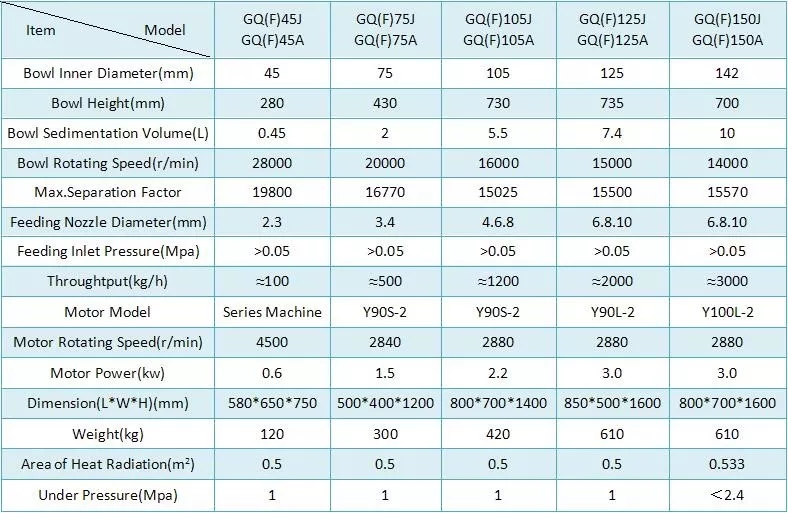

Parameter show:

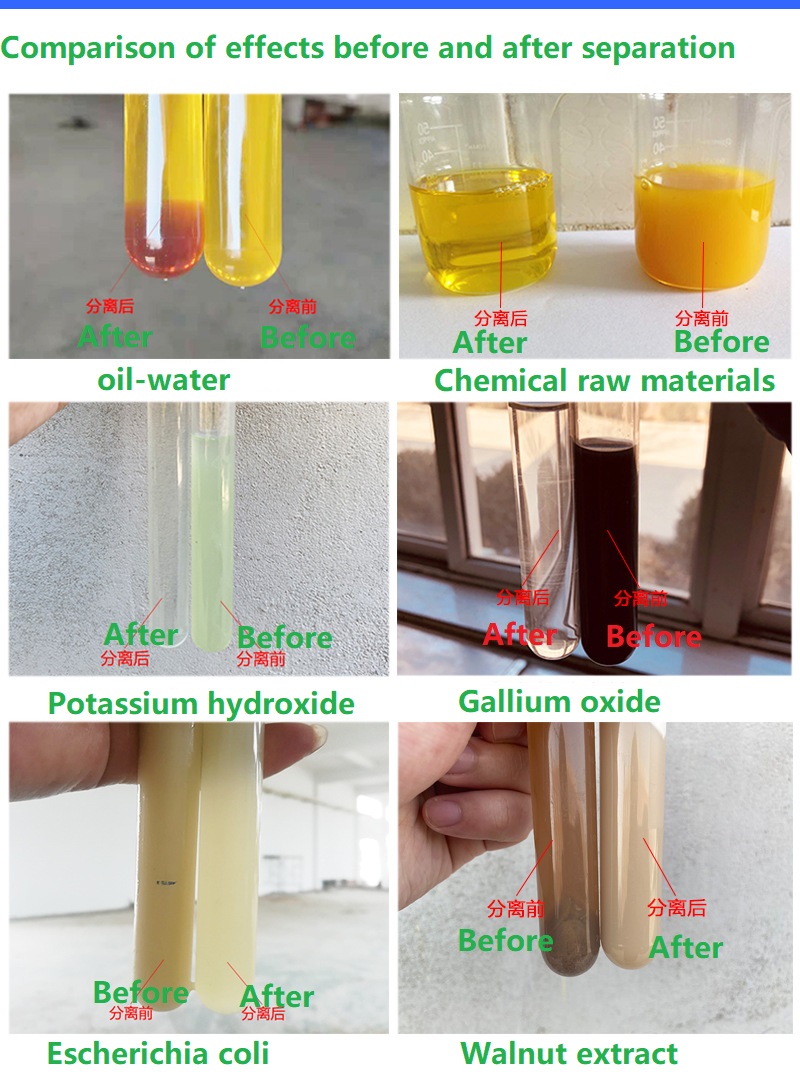

Separation effect show:

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the tubular bowl centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the tubular bowl centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Drilling mud decanter centrifuge and an unforgettable experience of partnering with us.

In essence, a long-standing tubular bowl centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1