Experience ultimate performance with our 2 phase Centrifuge Separator designed for the Whey Industry. This high-performance separator offers continuous feeding, high separation factor, and automatic residue discharging for optimal efficiency. With a powerful motor driving the drum in high-speed rotation and a concise bowl design, our separator ensures stable operation and perfect separating affection, making it the ideal choice for your processing needs. Enhance your operation with the DHSZ series separator, providing operating stability and a completely sealed inlet and outlet system for a smooth and efficient process. Trust in Liaoyang Shenzhou Machinery Equipment Co., Ltd for all your pharmaceutical and chemical machine needs, with a commitment to innovation and quality in every product.

We are a leading manufacturer in the centrifuge separator industry, specializing in high-performance whey industry applications. Our advanced technology and expertise in centrifugal separation ensure top-quality results for our clients. With a strong focus on innovation and customer satisfaction, we are committed to providing the most efficient and reliable solutions for whey processing. Our dedication to quality assurance and continuous improvement sets us apart in the industry, making us the preferred choice for businesses looking to maximize their production efficiency. Trust in our expertise and experience to take your whey processing to the next level with our high-performance centrifuge separator.

With a focus on delivering top-notch quality and high-performance solutions to the whey industry, our centrifuge separator is designed to meet the demands of modern production processes. As a leader in the field, our company has a strong reputation for innovation, reliability, and efficiency. We pride ourselves on our commitment to customer satisfaction and continuously strive to exceed expectations with our cutting-edge technology and superior service. Trust us to provide you with a centrifuge separator that is not only highly effective in separating whey efficiently but also sets the standard for durability and performance in the industry.

Product Description of Whey Industry centrifuge separator

Procss of Whey Industry centrifuge separator

Cleaning Of Whey

Main Structure

Specification

Model | Treatment capacity (L/H) | Inlet Pressure (Mpa) | Outlet pressure (Mpa) | Motor power (Kw) | Weight (Kg) | Outline dimension (mm) |

DHSZ360 | 1200-2500 | 0.05 | 0.1-0.25 | 7.5 | 1280 | 1500*1150*1500 |

DHSZ470 | 2500-7000 | 0.05 | 0.1-0.25 | 15 | 1880 | 1800*1200*1800 |

DHSZ550A | 5000-10000 | 0.05 | 0.1-0.25 | 18.5 | 2200 | 1850*1550*2050 |

DHSZ550E | 6000-15000 | 0.05 | 0.1-0.25 | 22 | 2200 | 1850*1550*2050 |

DHSZ700 | 15000-30000 | 0.1 | 0.2 | 30 | 3300 | 2100*1650*2300 |

Advantage

1. Operating stabilityOur service

12. Guide you do the normal maintenance.

13. Suggestions and any comments &reflection from customer would be treated in priority.

14. Markting team will visiting if you need.

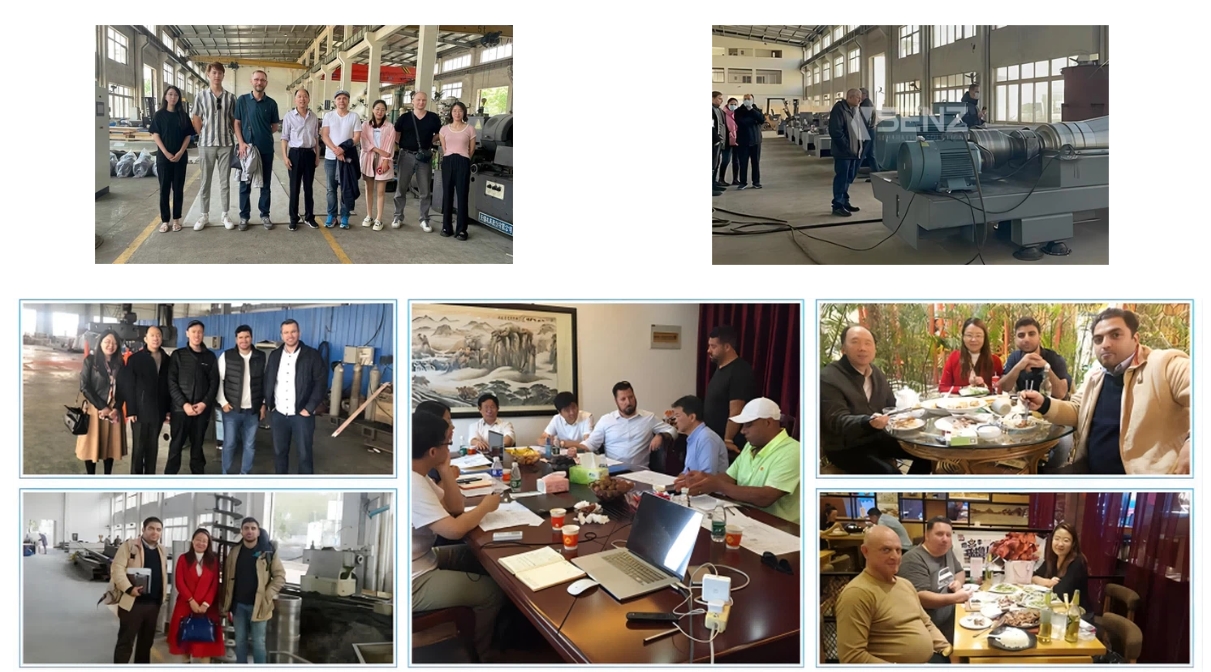

Cutomers visited Shenzhou Group from other countries

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1