The 3 phase centrifuge from SHENZHOU is designed for dairy separation with features like large capacity, high efficiency, and lower energy consumption. The advanced inlet and outlet design ensures soft treatment during separation, preserving product quality. With high rotating speed, operating stability, and perfect separating affection, this centrifuge is ideal for various applications in the dairy industry such as hot milk separation, whey protein separation, and syrup clarification.

At High-Speed Dairy Separation, our team strength lies in our deep expertise in centrifuge technology and our dedication to delivering high-quality products to our customers. Our team of engineers and technicians work tirelessly to ensure that our 3-phase centrifuge for dairy separation is top-notch in terms of performance and durability. With years of experience in the industry, we have honed our skills and knowledge to create a product that exceeds expectations. Our commitment to excellence and customer satisfaction is what sets us apart, making us the go-to choice for all your dairy separation needs.

Team Strength: Our High-Speed 3-Phase Centrifuge for Dairy Separation is backed by a team of experts with extensive experience in dairy processing equipment. Our engineers have designed this centrifuge to maximize efficiency and provide precise separation of cream, skim milk, and whey. The technical support team is available around the clock to answer any questions and provide solutions to any issues that may arise. With a strong emphasis on collaboration and innovation, our team ensures that this centrifuge meets and exceeds the industry standards for dairy separation equipment. Trust in our team's expertise to deliver top-quality results every time.

Product Details

The milk has so wide diversity, even the simplest milk sold on the market contains different fat contents. If list, there are so many types of dairy products to be mentioned, such as butter, cheese, quark, yogurt etc.

SHENZHOU dairy separator has such features as large capacity, good deoiling performance, high efficiency and lower energy consumption. The advanced inlet and outlet design guarantees soft treatment during the whole separation process, preventing destructive air from entering and ensuring product quality.

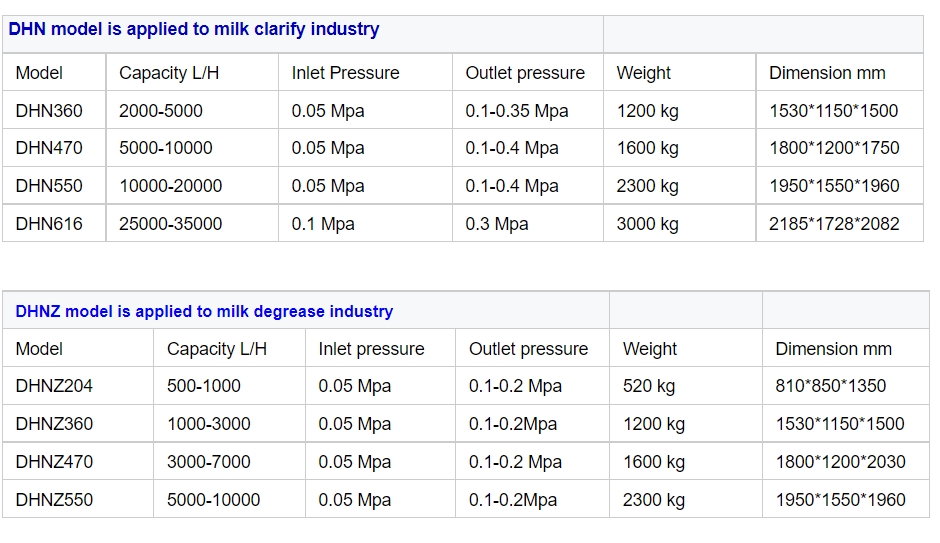

Technical parameter

Technical parameter

Working principle

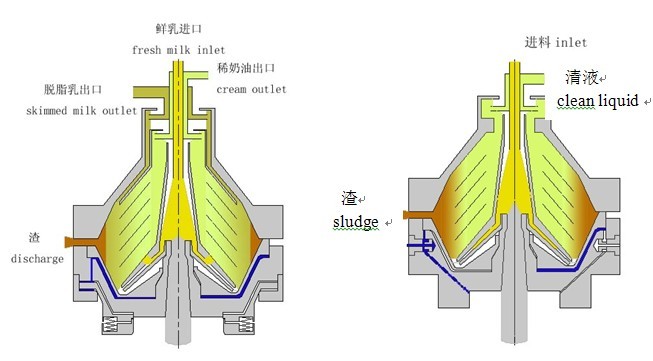

2 Phase Separator working principle for milk clarify industry

Clarification mean two phase separation. The materials are feeding into the heart parts of this machine, the inside of the bowl. Under the action of strong centrifugal force, the impurity will be removed from the raw material then get the clean milk.

3 Phase Separator working principle for dairy skimming

The disc separator is specially used for the two-phase and three-phase separation. The two-phase separation is to separate the s uspended solid from liquid or s eparate two liquids which have the different specific gravity and are immiscible. The three-phase separation is to separate the two immiscible liquid phases and a phase of solid at the same time .

Product Features:

1 . High rotating speed 4 . Lower noise

2 . Operating stability 5 . Perfect separating affection.

3 . Completely sealed up of the inlet and outlet system

Application:

1) Hot milk separation

2) Cold milk separation

3) Whey protein separation

4) Buttermilk separation

5) Dairy whey clarification

6) Disinfection of dairy products

7) Casein

8) Syrup clarification

9) Vegetable juice clarification

10) Tea drinks, coffee, Beer and other liquid clarification

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1