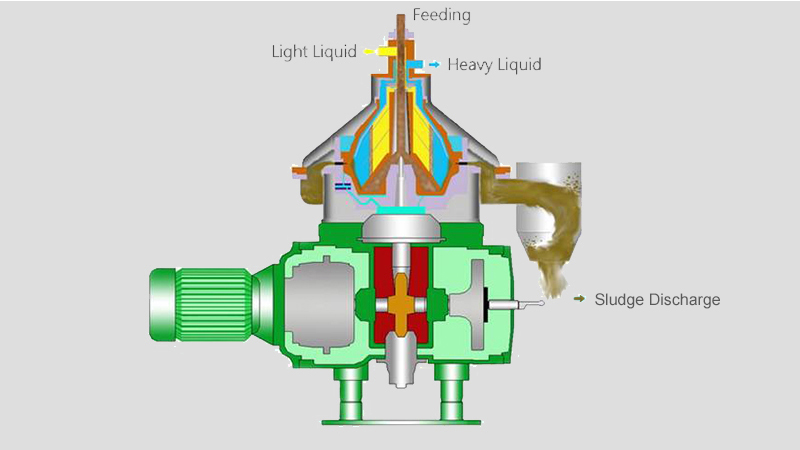

3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation.

The 3 phase disc centrifuge is a high-speed, efficient, and automatic slag discharge separator used for liquid-liquid-solid separation. With two liquid discharge ports and one slag discharge port, it can separate two liquids with different specific gravity simultaneously. Operating at up to 12000G force, this centrifuge offers thorough separation of liquids and clearer liquid phase discharge compared to decanter centrifuges.

At High-Speed 3 Phase Disc Centrifuge, our team strength lies in our unwavering commitment to delivering top-notch performance and efficiency. Our skilled engineers and technicians work seamlessly together to ensure that every product we produce meets the highest quality standards. With years of experience in the industry, our team is well-equipped to tackle any challenges that come our way, allowing us to provide our customers with reliable and innovative centrifuge solutions. Our dedication to continuous improvement and customer satisfaction sets us apart from the competition, making us the trusted choice for all your separation needs.

Harness the power of team strength with our High-Speed 3 Phase Disc Centrifuge. Designed for efficiency and precision, this centrifuge is a testament to the collaborative efforts of our skilled engineers and technicians. Our dedicated team has worked tirelessly to ensure that each component of this machine is crafted with perfection, guaranteeing optimal performance and reliability. With a focus on teamwork and innovation, we have created a product that surpasses industry standards and meets the needs of our customers. Trust in the strength of our team to deliver a centrifuge that exceeds expectations and revolutionizes your workflow.

3 PHASE DISC STACK SEPARATOR WORKING PRINCIPLE

In essence, a long-standing 3 phase disc centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the 3 phase disc centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The buyers of 3 phase disc centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the 3 phase disc centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1