High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation.

Our High Speed Tubular Centrifuge offers continuous separation with superior efficiency and performance. Its innovative design allows for rapid separation of solid particles and liquids, making it ideal for various industrial applications. With its high speed rotation and robust construction, this centrifuge provides reliable and consistent results, giving you peace of mind in your operations.

Company Profile:

With a commitment to technological innovation and customer satisfaction, our company specializes in manufacturing high-speed tubular centrifuges for continuous separation processes. Our centrifuges are designed to efficiently separate particles and liquids, offering fast and effective solutions for various industries. Our team of experts ensures that each product is built to the highest quality standards, providing reliable performance and long-lasting durability. We prioritize customer service and strive to meet the unique needs of each client, offering personalized solutions and support. Trust in our company for high-speed tubular centrifuges that deliver exceptional results every time.

At our company, we are dedicated to providing efficient and innovative solutions for various industries. Our High Speed Tubular Centrifuge is a cutting-edge technology that offers continuous separation for a wide range of applications. With a focus on quality and performance, our centrifuge is designed to meet the needs of our customers, providing reliable and consistent results. We take pride in our commitment to excellence and customer satisfaction, striving to deliver high-speed and reliable products that exceed expectations. Trust in our company for all your separation needs and experience the difference our centrifuge can make in your operations.

Equipment Characteristics

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

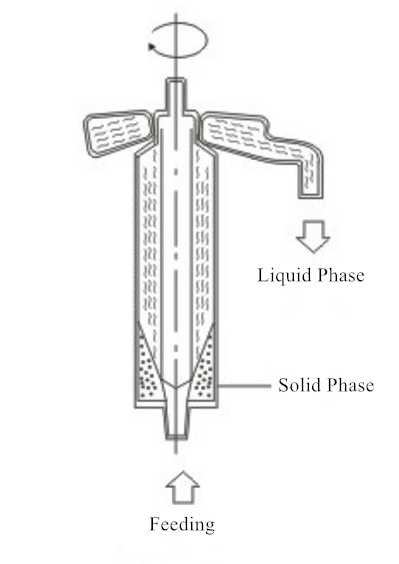

GQ Clarification Tubular Centrifuge

GQ Clarification Tubular Centrifuge

(Liquid phase-solid phase)

The GQ type is mainly used for a variety of difficult-to-separate suspensions in the separation industry, and is especially suitable for the separation of solid-liquid two-phase separations with thin concentration, fine particles and small specific gravity differences.

GQ Working Principle:

1. The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted via the control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2. The density of the liquid in the suspension is relatively small, and it spirally rises gradually from bottom to top and then continuously discharges from the clear liquid outlet on the upper part of the rotor;

3.The solid phase is relatively heavier, and it will settle inside the bowl. After the solid is collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, you need to reset the rotor installation, and then start the next separation process.

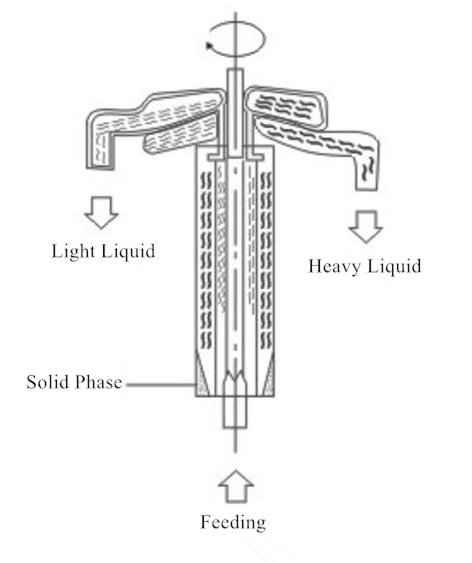

GF Separation Tubular Centrifuge

(Light liquid-heavy liquid-solid phase)

The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities.

GF Working Principle:

GF Working Principle:

1.The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet;

3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, need to re-install the rotor, and then start the next separation process.

FEATURES OF HIGH SPEED TUBULAR CENTRIFUGE

FEATURES OF HIGH SPEED TUBULAR CENTRIFUGE

The enclosure shape is of square shape and round shape.

Stainless steel 304 is used for the surface wrapping of the enclosure.

Stainless steel 316L for the parts in contact with the suspension.

The enclosure body with door-opening design is convenient for disassembly and assembly of the bowl, reduces labor intensity and the separation effect is not affected.

Optional VFD control cabinet, start by inverter, adjustable speed, reduce the starting current and the degree of damage to the transmission components and wear parts, and improve the service life of the equipment and the motor.

The control cabinet is optionally equipped with PLC and touch screen to display the speed and temperature.

According to the field of use, explosion-proof type and cooling type with cooling coil are available.

Mobile integrated base is available.

Product Introduction

Solid in the drum .

With .Control .cabinet.

Company Introduction

Regarding the attributes and functionality of the continuous tubular centrifuges, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Decanter Centrifuge and an unforgettable experience of partnering with us.

The buyers of continuous tubular centrifuges come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Regarding the attributes and functionality of the continuous tubular centrifuges, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1