The High Speed Tubular Centrifuge for Nano Particle Separation is a cutting-edge 2 Phase Centrifuge that utilizes a high running speed to separate heavy liquid forming the outer ring and light liquid forming the inner ring. This separator operates with a strong centrifugal force field, allowing for effective separation of difficult-to-separate suspensions with fine particles and different gravity levels between the two phases. With a flexible shaft upper drum and damping floating bearing lower drum, this centrifuge offers efficient and reliable performance for various industrial applications.

We are a leading provider of high-speed tubular centrifuges for nano particle separation, offering top-of-the-line 2 phase centrifuge technology. Our company is dedicated to providing innovative solutions for efficient and precise separation processes, empowering industries to achieve optimal results. With a commitment to quality and performance, we pride ourselves on delivering superior products that deliver consistent results. Our expertise in centrifuge technology ensures that our customers receive the most advanced and reliable equipment on the market. Trust us to meet your separation needs with precision, speed, and reliability.

Our company specializes in the design and manufacturing of high-speed tubular centrifuges for nano particle separation. With cutting-edge technology and precision engineering, our 2 Phase Centrifuge is capable of separating particles with incredible efficiency. Our team of experts are dedicated to providing top-of-the-line products that deliver reliable and consistent results for our customers. We pride ourselves on our commitment to innovation, quality, and customer satisfaction. Trust us to meet your centrifugation needs with a product that exceeds expectations and sets the standard in the industry. Experience the difference with our high-speed tubular centrifuge for nano particle separation.

Product Description

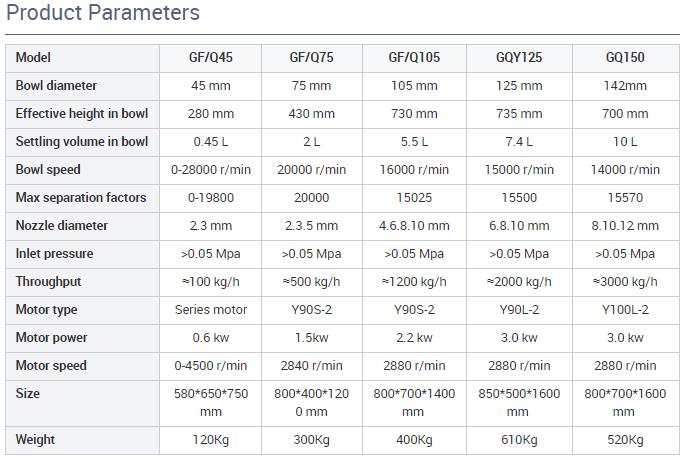

Product parameters

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1