After years of solid and rapid development, Shenzhou has grown into one of the most professional and influential enterprises in China. 3 phase centrifuge Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product 3 phase centrifuge or our company, feel free to contact us.Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has won a higher rating among the broad customer base.

Products Description

The Palm Oil Clarifier Decanter Centrifuge is a specialized equipment designed for the separation and clarification of palm oil in the palm oil processing industry. It effectively separates the oil from impurities such as solids, water, and sludge, ensuring high-quality palm oil production. It is widely used in the production of chemical, printing, metallurgical coal mine, oil production, metallurgy ,iron and steel, fabric ,food, drink, pharmacy starch, dyes and so on, and it can also solve industrial and municipal wastewater. By use it, solid can be dehydrated, liquid can be clarified, etc.Shenzhou decanter centrifuge uses centrifugal and sedimentation principles to separate liquid with density difference. Our factory's centrifuges can clarify, dehydrate and classify suspensions with solid-phase particles of 0.002-3 mm and thickness range of 0.5-40%. According to feed feature, product can be divide into LW two-phase separator and LWS three-phase separator. They are widely used in industries such as food processing, petrochemical/oil, waste recycling, mineral processing, light industry, and environmental protection.

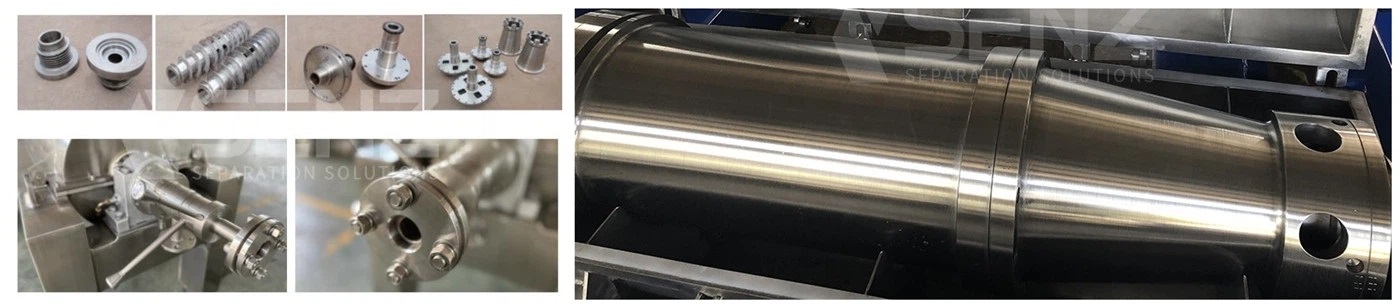

1. Structure

Main body of decanter centrifuge are consist of column-taper drum, helical pusher, speed difference system, shaft seat, frame, enclose, main and auxiliary motor and electric system. Main motor drive drum, auxiliary motor drive planetary gear differential, so that create different speed between drum and screw, then carry on continual separation in 24 hours under the strong centrifugal force which produced by the high speed rotate of separator.

2. Operation Principle

Drum and screw rotate at a certain different speed. The feed enters the drum through a stationary inlet tube and is accelerated smoothly by an inlet rotor. The resulting centrifugal forces make the solids collect on the wall of the drum. Screw conveyor continual moving the solid to conical end of drum, discharge through discharge port after dried in the dry area, however, light liquid forms the inner layer and effusion through overflow port of drum, then discharge through liquid outlet port.

3. Product Characteristics

Lower cake transportation costs due to very dry solids

Better recovery of nutrients due to very high separation efficiency

Lower fresh water consumption compared to other processes

Continuous and fully automatic operation

24hr operating reliability

Optimum wear protection

Energy saving design

Easy to operate

Easy to maintain

Simple assembly/dismantling

4. Following Allocation Could Be Available To Meet Customer’s Demand

Frequency conversion plus PLC controlling system

Protection system for vibration and temperature rising

Feeding speed control

Gas-liquid separation device on liquid outlet

Other allocation demand

5. Features

* All parts coming into contact with the product are made of stainless steel.

* 3-phase AC motor for controlled torque starting via frequency converter

* Approximately 80 to 90 % of the oil is recovered.

* Low personnel costs due to continuous and automatic operation.

* Highest g-force for higher solids output

* Adjustable bowl speed via VFD

* Automatic adjustment of differential speed via VFD

* Two motor drive

* Belts for both primary motor and secondary motorFeatures

* All parts coming into contact with the product are made of stainless steel.

* 3-phase AC motor for controlled torque starting via frequency converter

* Approximately 80 to 90 % of the oil is recovered.

* Low personnel costs due to continuous and automatic operation.

* Highest g-force for higher solids output

* Adjustable bowl speed via VFD

* Automatic adjustment of differential speed via VFD

* Two motor drive

* Belts for both primary motor and secondary motor

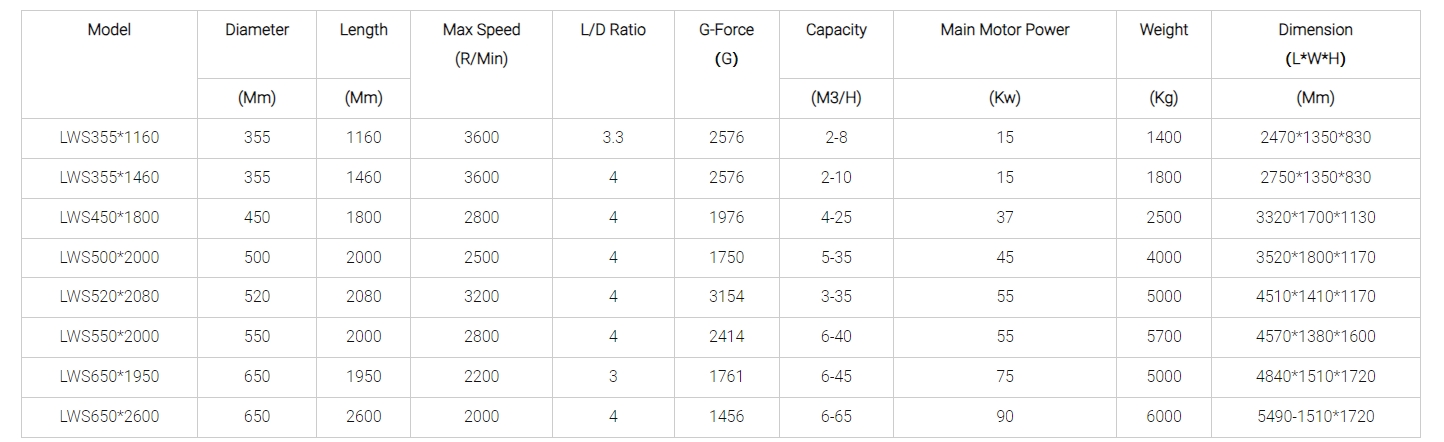

Technical Parameters:

Application Cases

1. Areas Of Application For 3 Phase Decanters

3-phase decanters (respectively separation decanters) are used for the clarification and simultaneous separation of fluids of different densities.The three phase decanters perform a 3 phase separation (solid-liquid-liquid separation) of dispersions of solid material and two non-mixable liquids of different densities.

2. Typical Areas Of Application For 3-Phase Are Thus

* Treatment of sludges containing oil

* Separation of oil-water emulsions contaminated by solid materials

* Extraction of animal and plant oils and fat

* Furthermore * Fish press water from the fishmeal industry

* Manufacturing starch

* Olive oil

3. Functional And Constructional Characteristics Of 3-Phase Decanters

Due to the high rotational speed of the drum solid material particles are deposited on the inner wall of the drum; at the same time the two liquids are separated from each other. The solid material particles spun off to the outside are continuously transported to the solid material discharge by the integrated screw conveyor. The two liquid phases, separated from each other and almost completely free of solid material, overlay each other according to their density and leave the separation chamber by separate openings at the opposite end of the drum (cylindrical drum end). The two liquid phases can either be discharged freely (e.g. over a weir) or under pressure (by means of an integrated pump; peeling plate also called gripper).

Packing & Delivery

Hot Tags: palm oil clarifier decanter centrifuge, China palm oil clarifier decanter centrifuge manufacturers, suppliers, factory, oil water treatment, testing equipment, lagoons oil sludge treatment decanter, refining sunflower oil, tailing disposal, essential oil separator

The buyers of 3 phase centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 3 phase centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 3 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Decanter Centrifuge and an unforgettable experience of partnering with us.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the 3 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1