According to the function of the tube separator, our company separates the tube separator into clarification type (GQ) and separation type (GF). The main function of the clarifier tube separator is to handle the separation of liquid and solid phases. The main function of separation centrifuge is to deal with liquid and liquid and a small amount of solid three-phase separation.

Our Oil Water Centrifuge - GQ/GF Tubular Centrifuges are designed for efficient separation of oil and water mixtures, making them ideal for various industrial applications. These centrifuges boast high-speed rotation capabilities, ensuring rapid and effective separation of liquids. With a compact and easy-to-operate design, our centrifuges are a reliable and cost-effective solution for any separation needs.

At our company, we are dedicated to serving our customers with top-of-the-line oil water centrifuges like the GQ/GF Tubular Centrifuges. Our focus on quality and performance ensures that you receive a reliable and efficient product that meets your needs. We serve by providing excellent customer service, technical support, and expert advice to help you make the most out of our centrifuges. With a commitment to innovation and customer satisfaction, we strive to exceed expectations and deliver exceptional value to our clients. Trust us to serve you with the best centrifuge solutions for your oil water separation needs.

At our company, we serve our customers with top-of-the-line Oil Water Centrifuges. Our GQ/GF Tubular Centrifuges are designed to efficiently separate oil and water, making them ideal for a wide range of industrial applications. With a focus on quality and reliability, our centrifuges are built to last and provide excellent performance. We serve our customers by offering a product that meets their needs and exceeds their expectations. Trust us to deliver durable and effective centrifuges that will help streamline your operations and improve efficiency. Experience the difference our products can make for your business today.

GQ/GF series tubular centrifuges, oil water separator centrifuge manufacturers & suppliers

According to the function of the tube separator, our company separates the tube separator into clarification type (GQ) and separation type (GF). The main function of the clarifier tube separator is to handle the separation of liquid and solid phases. The main function of separation centrifuge is to deal with liquid and liquid and a small amount of solid three-phase separation.

Tubular centrifuge working principle:

The main shaft drives the drum to rotate at high speed around its own axis, forming a strong centrifugal force field in the drum. The material enters the drum from the bottom inlet. Under the action of centrifugal force, the material is forced to flow upward along the inner wall of the drum, and two concentric liquid rings are formed in the axial direction according to the density difference. The light liquid is discharged from the light liquid port near the axis and recovered through the light liquid collecting pan. The heavy liquid is discharged from the heavy liquid port near the drum wall. , Manually cleared after shutdown.

Tubular centrifuges main purpose:

It is used for the separation of emulsions with little difference in density between liquid and liquid phases. It is widely used in biomedicine, Chinese medicine clarification, bacterial recovery, blood products, plant extraction, health food, beverage, chemical industry and other industries.

Tubular centrifuges main feature:

1. Vertical structure, small footprint.

2. Flexible shaft system, overhanging support of the drum, upper transmission.

3. The transmission mechanism has a fully enclosed cover to prevent dust pollution during transmission.

The inner and outer surfaces are mirror-polished, and the surface roughness can reach Ra0.2-0.4um, which complies with GMP specifications.

Tubular centrifuge configuration selection:

1. External structure: cylindrical front door, closed cylinder, front door, square box, swing, etc.

2. Motor drive: ordinary motor, explosion-proof motor, variable frequency motor

3. Method of cloth: flat center cloth, conical center cloth

4. Online cleaning: spray ball, spray pipe

5. Transmission housing: fully enclosed, semi-enclosed

6. Drum disassembly: mobile robot, mobile workbench

7. Temperature control: cooling coil

8. Electrical components: brand supply

9. Surface treatment: mirror polishing, brushing, matt

10. Safety control: variable frequency control, nitrogen protection, vibration protection, speed monitoring, overload protection, door opening protection, electromechanical interlocking

Tubular centrifuges material selection:

1. Stainless steel 304, 321, 316, 316L

2. Carbon steel or cast iron lined stainless steel body

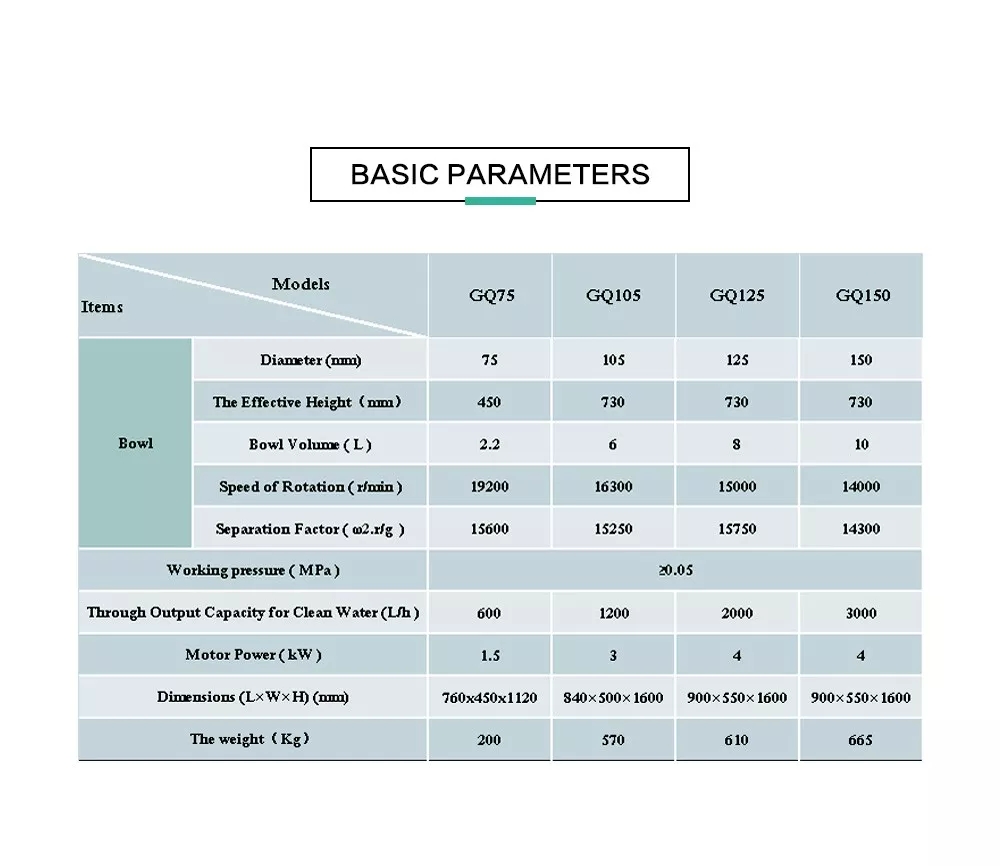

Tubular centrifuges technical parameters:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1