The oilfield centrifuge is a specialized piece of equipment designed for the drilling industry. Our centrifuge is highly efficient in the separation of unwanted solid materials from drilling fluids, facilitating the reuse of these fluids. Additionally, during the purification of drilling mud, it enables the recovery of valuable barite. This ensures the overall process flow remains intact and provides a reliable sequence of operations. Shenzhou oilfield centrifuges find extensive application in treating oily sludge, managing oily (waste) water, addressing solid waste in drilling oil-based mud, and executing three-phase oil sludge separation systems.

The drilling mud decanter centrifuge is a critical piece of equipment in the oil and gas industry, effectively separating various components within a mixture using centrifugal force. It operates at specific RPM settings, generating the necessary centrifugal force to separate substances like oil and water. With its robust design and high-speed centrifugation process, this industrial centrifuge is ideal for applications in the oilfield, including barite recovery, dewatering, and purification processes.

At Oilfield Decanter Centrifuge, our team strength lies in our unwavering commitment to efficiency and excellence in mud purification. Our dedicated engineers work tirelessly to ensure that our centrifuges are of the highest quality, delivering unparalleled performance and reliability in the field. With years of expertise and innovation, our team continuously strives to push boundaries and set new standards in the industry. Together, we collaborate seamlessly to address challenges and meet the evolving needs of our customers. Trust in our team's expertise and experience to provide you with the most efficient mud purification solutions for your oilfield operations.

Our Oilfield Decanter Centrifuge is a testament to our team's strength in innovation and efficiency. With years of experience and expertise in mud purification, our dedicated team has developed a solution that ensures optimal performance in oilfield operations. Our engineers and technicians work tirelessly to deliver a product that meets the highest standards of quality and reliability. Trust in our team's commitment to excellence and let us help streamline your mud purification process for maximum efficiency and productivity. Choose our Oilfield Decanter Centrifuge and experience the power of a strong team behind every successful operation.

The oil and gas drilling fluid purification horizontal spiral discharge sedimentation centrifuge (LW series frequency conversion centrifuge - dual motor dual frequency conversion type) is a large displacement model developed for high speed and large processing capacity. It is designed for an integrated frame body, which is convenient for on-site installation and lifting; Explosion proof, corrosion proof, weather proof and shock absorption treatment are adopted. Frequency converter and other electrical components are installed in the flameproof cabinet. The flameproof cabinet is equipped with heating and ventilation system, which is suitable for field operation.

The screw pusher is driven by planetary gear reducer, with mechanical and electrical overload protection device, it can realize power transmission of low speed and large torque, and the equipment can be started stably. The equipment has single motor drive, variable frequency dual motor drive, hydraulic drive and other forms, which are selected according to different conditions of users.

The equipment is used for solid particles with diameter ≥ 2 μ The separation of m suspension and the treatment of drilling mud and liquid have high recovery rate and effective solid phase control. It can operate stably for a long time at 0-4000 Rpm speed, and the centrifugal force generated can reach 3180G. The solid control system is used in oil drilling (drilling fluid tail slurry), trenchless, coalbed methane and other fields to remove harmful fine solid particles such as rock cuttings from the mud, or recover valuable weighting materials such as barite, saving costs.

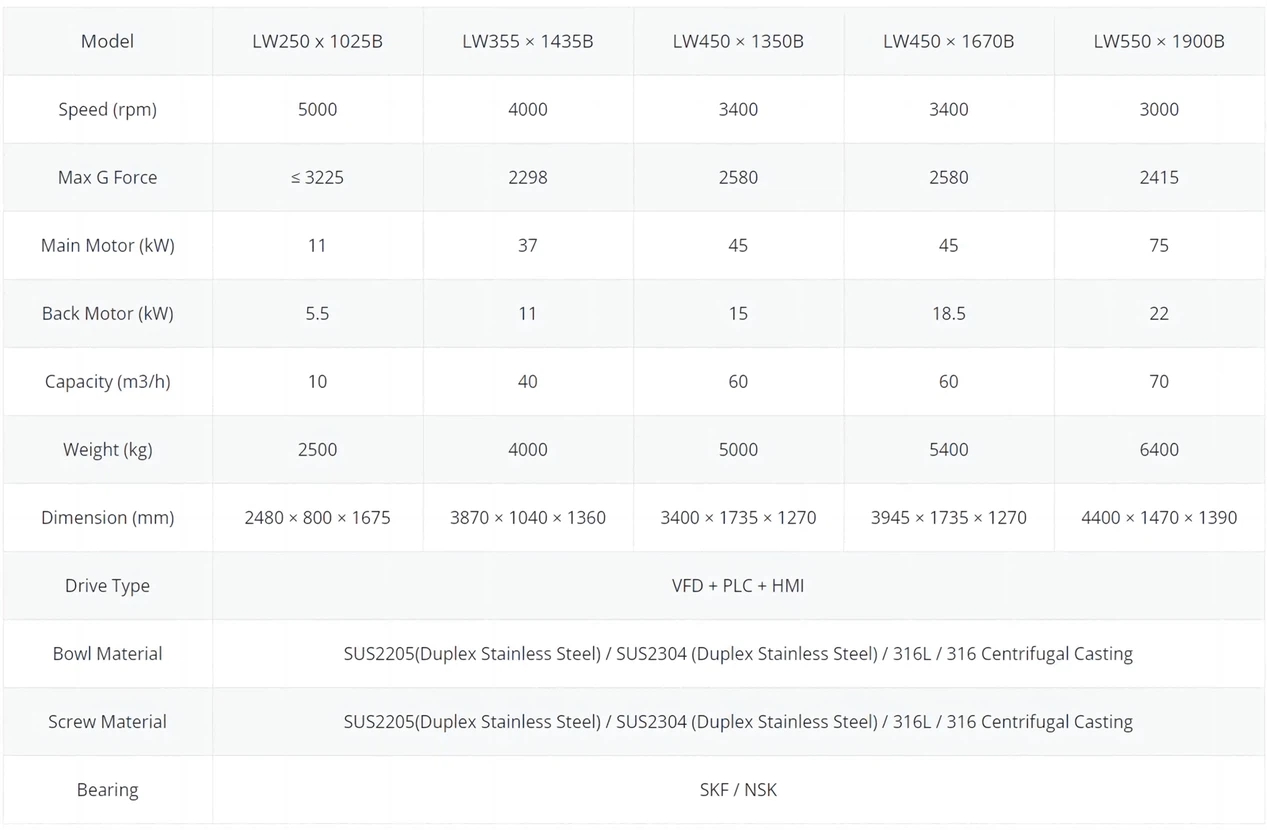

Oilfield Decanter Equipment Parameters

The oilfield decanter centrifuge, a critical piece of separation equipment in the petroleum industry, employs centrifugal force to effectively separate various components within a mixture. It operates at specific RPM (revolutions per minute) settings to generate the necessary centrifugal force, allowing for the separation of components like oil and water. This industrial centrifuge, also known as a solid bowl centrifuge, serves the purpose of efficiently separating different substances in the oilfield, including waste oil, mud, and drilling fluids. Its robust design and high-speed centrifugation process make it ideal for applications in the oil and gas industry, as well as in food processing, chemical industry, and other industrial settings. The centrifuge's operation involves the utilization of centrifugal force to separate solid and liquid phases, and its versatile capabilities cater to a wide range of industrial needs, including barite recovery, dewatering, and purification processes. It comes in various models and capacities, and the choice of centrifuge type and settings depends on specific requirements, such as RPM, G-force, and centrifugation materials. The centrifuge is a valuable piece of equipment, known for its reliability and efficiency in a variety of industries, including the oil and gas sector, where it plays a vital role in separating and purifying different components for further processing.

Customers visited Shenzhou Group :

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Production Line equipment and an unforgettable experience of partnering with us.

The buyers of drilling mud decanter centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. drilling mud decanter centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the drilling mud decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the drilling mud decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1