Guided by scientific and technological innovation, Shenzhou always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. 2 phase disc Centrifuge Today, Shenzhou ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product 2 phase disc Centrifuge and our company by directly contacting us.Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has a reputation for excellent service and the nice 2 phase disc Centrifuge.

Product Description of Bacteria disc stack centrifuge

Disc centrifuge is a kind of vertical centrifuge. The drum is installed on the upper end of the vertical shaft, which is driven by the motor through the transmission device. There is a set of disc-shaped parts in the drum, which are overlapped with each other. There is a small gap between discs. The suspension (or emulsion) is added to the drum through the feed pipe in the center of the drum. When the suspension (or emulsion) flows through the gap between the discs, the solid particles (or droplets) settle on the discs under the action of centrifuge to form sediment (or liquid layer). The sediment slides along the surface of the disc and gets away from the disc and accumulates in the part with the largest diameter in the drum. The separated liquid is discharged from the outlet of the drum. The function of disc is to shorten the settling distance of solid particles (or droplets) and expand the settling area of the drum. The production capacity of the separator is greatly improved due to the installation of disc in the drum.

Two Operations Method of Bacteria disc stack centrifuge

1. Liquid solid separation (i.e. separation of bottom concentration suspension), which is called clarification operation, that is two-phase separation.

2. Liquid-liquid separation (or liquid-liquid-solid) separation (i.e., the separation of emulsion) is called separation operation, that is three-phase separation.

The disc separator is specially used for the two-phase and three- phase separation. The two-phase separation is to separate the suspended solid from liquid or two liquids which have the different specific gravity and are immiscible. The three-phase separation is to separate the two immiscible liquid phases and a phase of solid at the same time. This automatic discharging separator has the traits as high rotating speed, operating stability, completely sealed up of the inlet and outlet system, lower noise and fine separating effect. Centripetal pump system designed by our professional designer has the traits as stable outlet pressure, large regulating sphere and operating easily. It has professional automatic domination case with safety protection device and advanced automatic vibrating testing instrument which can view vibrating number at any time. We can make the best separating and discharging by adjusting separating parameter directly at the screen.

Advantage of Bacteria disc stack centrifuge

) High speed, stable operation, all import and export systems are sealed, noise is low, and separation effect is good.

2.) The professionally designed centripetal pump system has stable output pressure, large adjustment range and convenient operation.

3.) The drum has a special structure, which has a large processing capacity and good degreasing and clarifying effect.

4.) Professionally designed automatic control cabinet, can observe the vibration value of the equipment at any time.

Working Principle of Bacteria disc stack centrifuge

There is a set of disc-shaped parts in the drum, which are overlapped with each other. There is a small gap between discs. The suspension (or emulsion) is added to the drum through the feed pipe in the center of the drum. When the suspension (or emulsion) flows through the gap between the discs, the solid particles (or droplets) settle on the discs under the action of centrifuge to form sediment (or liquid layer). The sediment slides along the surface of the disc and gets away from the disc and accumulates in the part with the largest diameter in the drum. The separated liquid is discharged from the outlet of the drum. The function of disc is to shorten the settling distance of solid particles (or droplets) and expand the settling area of the drum. The production capacity of the separator is greatly improved due to the installation of disc in the drum. The solids accumulated in the drum are removed manually after the separator is shut down, or discharged from the drum through the slag discharge mechanism without shutting down.

Application Field of Bacteria disc stack centrifuge

Mineral Oil Industry:

Purification of fuel oil and lubricating oil for marine main engine, land diesel engine, power station, etc;

Dairy Industry:

Clarification, purification and degreasing of fresh milk;

Vegetable Oil Industry:

Purification and clarification of palm oil, degumming, soaping, dehydration and dewaxing of vegetable oil refining, etc;

Beverage Industry:

Clarification of beer, juice and beverage, extraction of plant protein, wastewater treatment, etc.; clarification of bioengineering fermentation broth;

Starch Industry:

Concentration and classification of starch pulp;

Chemical Industry:

Purification or clarification of chemical raw materials;

Lanolin Industry:

Extraction of lanolin from wastewater and wool washing industry;

Latex Industry:

Purification and concentration of natural rubber emulsion;

Other Industries:

Such as laboratory, petroleum, coking, kaolin, pulp recovery, electrolyte treatment, wastewater treatment, environmental protection, etc., as well as animal and plant protein extraction, animal fat extraction and refining, separation of mixed fatty acids.

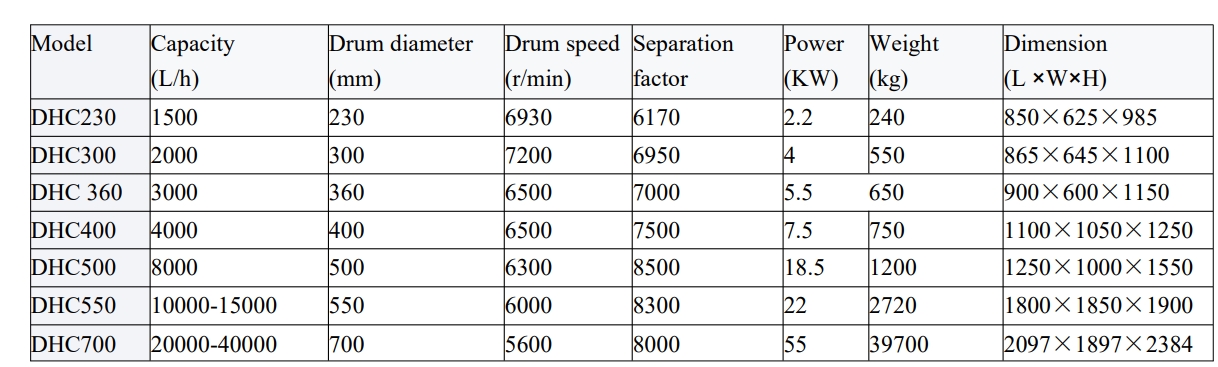

Technical Parameter of Bacteria disc stack centrifuge

Technical Service from Shenzhou Group :

24 hours online consult and service

2. Introduce the product to the customer in detail, answer the question raised by customer carefully;

3. Make different plans for choice according to the needs and requirements of customers;

After-sale Service:

1. Help to install and debug the equipment;

2. Provide 24 hours technical support by e-mail or phone;

3. Keep sufficient replaceable spare parts;

4. Help customers solve any other questions about products or other aspect;

5. Establish long-term and friendly relationship.

Service Commitment:

1. We will provide one-year warranty period to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

2. Consultant services for whole machine life, 24 hours technical support by email and telephone.

3. Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

Customers from other countries visited our factory.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Regarding the attributes and functionality of the 2 phase disc Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing 2 phase disc Centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The buyers of 2 phase disc Centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 phase disc Centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 2 phase disc Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1