LW(Environmental Decanter) series decanter centrifuge is designed for environmental industry for sludge dewatering, waste water treatment, waste oil recovery and treatment. It is also called solid bowl centrifuge, or decanter. The decanter centrifuge have been proved to be the most cost-effective solution for sludge treatment, waste water treatment and waste oil recovery include solids liquid separation, sludge dewatering and sludge thickening.The main target of separation from the liquid and solid phase is to get solid phase with the least possible residual moisture. And at the same time the decanter need to minimize possible solid particle residues in the separated liquid phase.

The SHENZHOU Environmental Decanter Centrifuge offers superior clarifying performance, thanks to its advanced design and precise engineering. With its high-speed rotation and efficient separation capabilities, this decanter ensures optimal results in separating solids from liquids. Its reliable and durable construction makes it a trusted choice for various industrial and environmental applications, providing users with a dependable solution for their separation needs.

At SHENZHOU, our team's strength lies in our unwavering commitment to producing top-quality environmental decanter centrifuges. With a dedicated and experienced team of engineers, technicians, and support staff, we ensure that every product meets the highest standards of performance and reliability. Our team's collaboration and expertise enable us to continuously innovate and improve our clarifying decanter, providing our customers with a solution that exceeds their expectations. Trust in SHENZHOU's team strength to deliver a centrifuge that not only clarifies effectively but also stands the test of time in the most demanding industrial environments.

At SHENZHOU, our team strength lies in our deep expertise and passion for delivering high-quality environmental solutions. Our talented engineers and technicians work tirelessly to design and manufacture top-of-the-line decanter centrifuges like the Clarifying Decanter. With a focus on innovation and sustainability, our team is dedicated to providing efficient and effective solutions for separating solids from liquids in various industries. Our commitment to excellence and customer satisfaction drives us to continuously improve and adapt to meet the evolving needs of our clients. Trust SHENZHOU for reliable and cutting-edge environmental decanter centrifuge technology.

Shenzhou Environmental Decanter Centrifuge Features & Benefits

SHENZHOU series centrifuge is specially designed for sludge treatment.

SHENZHOU series centrifuge bowl material is Duplex Stainless Steel 2304 made from centrifugal casting.

The screw conveyor inside the bowl is protected by Tungsten Carbide Tiles for longer operation.

SHENZHOU decanter reduce total disposal volume by as much as 70%

SHENZHOU decanter discharge stackable cake free of liquid

PLC and VFD controlled automatically operation to meet different applications.

Less people required, and low maintenance with continuous operation

Minimize footprint and easy installation.

The bearing is SKF premium bearing for reliable operation.

Compared to other separation equipment, the advantages of the decanter centrifuge are its wide range of potential use coupled with its continuous operation and ability to accept a wide range of feed material. The decanter centrifuge can be used for most types of liquid/solid separation. The function of the sludge treatment decanter centrifuge include dewatering sludge to dry cake, classification of solids in liquid suspension, or clarification of liquids and recovery of required solids.

SHENZHOU Sludge Treatment Decanter Centrifuge Application

Municipal or Industrial Sludge Dewatering

Industrial waste water treatment

Digested Sludge dewatering

Thickening of activated sludge

Animal Waste Treatment

Dissolved air flotation sludge treatment

SHENZHOU WASTEWATER DECANTER CENTRIFUGE

LW series are high performance decanter centrifuge designed for waste water treatment for different types of municipal and industrial wastewater.LW decanter centrifuges are widely used in municipal and industrial wastewater treatment plants for the purpose of producing a clean, safe water discharge within the required limits. As the environmental considerations and the consent limits are becoming more and more strict .The New waste water treatment plants built today are becoming more and more sophisticated, but to improve the efficiency of waste water treatment, the LW decanter centrifuges are extensively used for liquid-solid separation, sludge dewatering, and sludge thickening applications.

SHENZHOU Waste Water Decanter Centrifuge Features and Benefits

LW series centrifuge is widely used for waste water treatment around the world.

Continuous operation with optimized performance

Maximum the solids cake dryness to reduce disposal cost.

Minimum specific power consumption and polymer demand to save treatment cost.

Optimized operational labor costs by PLC and VFD controlled automatically operation.

Easy cleaning and hygiene by flushing without dismantling the machine for cleaning

Durable wear protection for the screw conveyor, solids discharge and slurry distribution port by Tungsten Carbide.

LW series centrifuge bowl material is Duplex Stainless Steel 2304 made from centrifugal casting.

Minimize footprint and easy installation.

The SHENZHOU decanter centrifuge can be used for more waste water treatment include but not limited to following:

Waste Water from Agricultural processing

Food processing and wastewater processes

Industrial manufacturing processes discharged waste water.

Waste sludge or water from Meat packing and rendering

Mining or Chemical processing waste water.

Paper processing waste water.

Potato and root crop processing

Steel production waste sludge and water.

Dewatering of municipal and industrial sludges

Dewatering the concentrated sludge off clarifier bottoms

Dewater the sludge off DAF systems

Thickening and dewatering of biological sludges

WASTE OIL DECANTER CENTRIFUGE

LW waste oil treatment or oil recovery decanter centrifuges specially equipped to meet the separation requirements of the waste oil processing industry with specialized separation equipment and systems technology. The LW decanter centrifuge series were designed and developed for high capacity waste oil treatment. Because of the special design, LW decanter centrifuge is capable to maximize the oil recovery, solids capture and cake dryness.

SHENZHOU not only provides the individual waste oil treatment decanter centrifuge, but also we can provide complete waste oil treatment or recovery package system. This typically include transfer pumps, premixing unit, primary screening machine (shale shaker), 2 phase decanter centrifuge, 3 phase disc centrifuge, chemical dosing system etc. This complete package is a turnkey solutions for clients for the waste oil treatment or oil recovery.

The main application of the waste oil decanter centrifuge include following:

Waste oil from storage tank bottom

Waste Oil sludge lagoons

Oil refineries slope oil or waste sludge

Oil water and solids mixtures from ship ballasts

Separation equipment discharged waste oil

Drilling waste oil from oilfield

Discarded lubricant oils and emulsions or other

Industrial waste oil and water and emulsion

The waste oil treatment system design vary depending on the make-up and source of the waste stream and also it vary because of the goal is different. But typically, the waste oil treatment system will include following:

Mechanical removal of solids by different separation machine.

Pre-mixing and Heating system to reduce viscosity and thus enhance mobility of waste material.

Chemical dosing to break emulsions and make oil, water and solids bound in the emulsion accessible for easier separation by G force.

In order to enhance solids removal rates and the discharged cake dryness, normally polymer will be used.

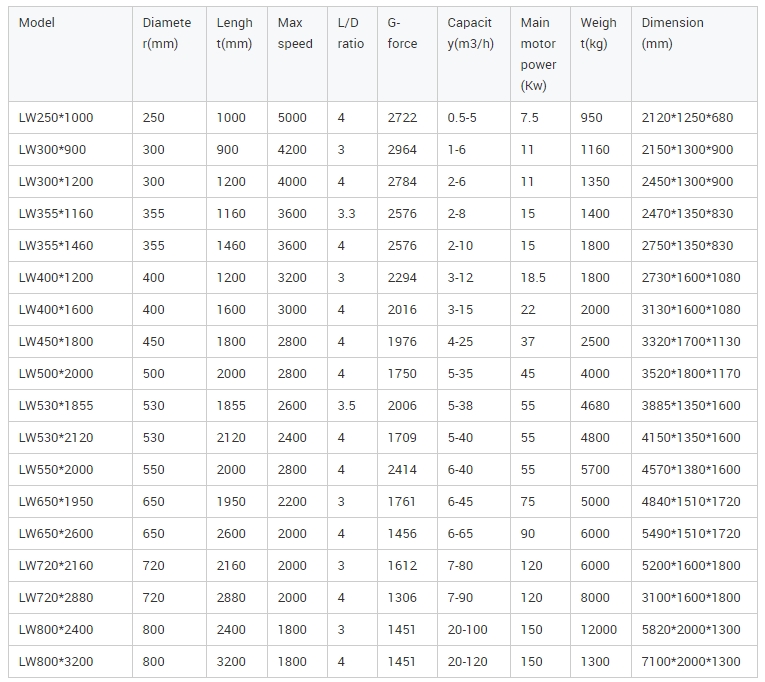

TWO PHASE TECHNICAL PARAMETER:

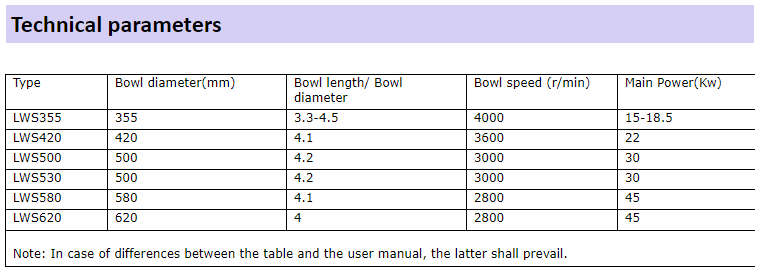

THREE PHASE DECANTER CENTRIFUGE PARAMTER:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1