Product Description

This type centrifuge is to be added such function as to remove the residual solid cake by pulling filter cloth with the removal rate higher than 99%, highly automated, has large capacity and can be remote-controlled.It is mainly used in the solid-liquid separation process of crystallized materials in such industries as pharmacy, food, gourmet power and chemistry.

Always striving toward excellence, Shenzhou has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. scraper centrifuge Today, Shenzhou ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product scraper centrifuge and our company by directly contacting us.The product is tested with the vigilance of our skilled professionals who have a clear understanding of the quality standards in the industry.

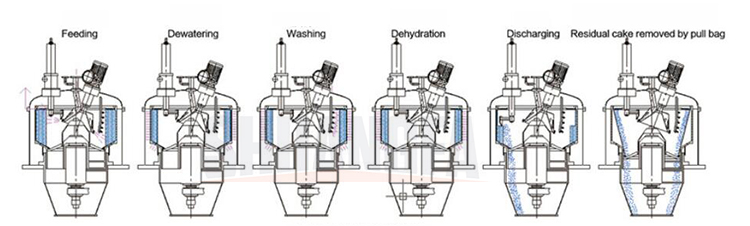

Working Principle of Automatic Scraper Bottom Discharge Centrifuge:

The liquid material feeded into the basket of the centrifuge that is rotating at high speed through a feeding pipe, and under action of the centrifugal field, the material passes through the filter cloth (screen) for filtration. Then the liquid phase discharges through the discharge pipeline, while the solid phase is retained in the basket. Feeding stops once the basket is filled with the material, then wash the solid cake, and discharge the washing liquid through filtration. The centrifuge continues to rotate to spin-dry the solid cake. After the solid cake meets the requirements for separation, the centrifuge reduces its speed, and removes the cake by means of the scraper, then discharges the cake out of the centrifuge. The centrifuge further reduces its speed so that the pneumatic pulling bag device moves reciprocally to shake off the residual solid cake, thus completely eliminating the solid cake.

Structure of Automatic Scraper Bottom Discharge Centrifuge, Bag-pulling Centrifuge:

Structure of Automatic Scraper Bottom Discharge Centrifuge, Bag-pulling Centrifuge:

Features of Products

1, Easy to replace the filter bag, with reliable self-locking. 2, Meet the GMP specifications and ant-explosion requirement, Large turnover or overall turnover cover+CIP online cleaning system. 3, Automatic scraper device, easy to discharding filter cake. 4, Small vibration, low noise and stable operation, convenient to maintenance. 5, Adopt the cake layer control device, effectively control the feeding amount of material, prevent the overload of centrifuge. 6, The basket, 100% weld flaw detection, high precision, large filtering area. 7, Full close structure, effectively prevent material from contamination, and ensure the safety of personnel. 8, Uniform distribution, reduce the distribution vibration. 9, Multiple safety protection, for example, overvibration protection, overcurrent protection, temperature control protection etc. 10, Cake removal rate higher than 99%.

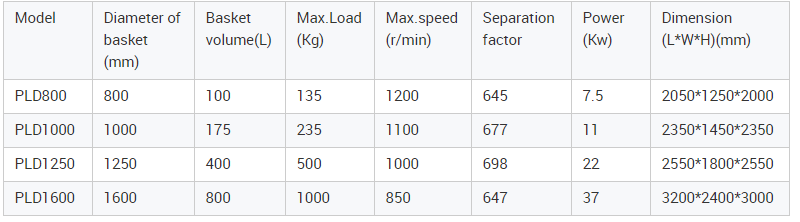

Paramter:

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. scraper centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing scraper centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The buyers of scraper centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Regarding the attributes and functionality of the scraper centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1