After years of solid and rapid development, Shenzhou has grown into one of the most professional and influential enterprises in China. 3 phase centrifuge Today, Shenzhou ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product 3 phase centrifuge and our company by directly contacting us.Customers think highly of our 3 phase centrifuge which is of high quality.

Product Introduction

Disc stack centrifuge is a kind of vertical centrifuge. As a high-efficiency, high-output, high-automation and high-speed precision separation equipment, it can be divided into solid-liquid two-phase and solid-liquid-liquid three-phase separation. As a two-phase separation disc centrifuge, it can separate most solid particles and liquids. As a three-phase disc centrifuge, it can separate liquid phases of different densities and separate solids at the same time.

Disc centrifuge is equipped with a PLC controller and CIP automatic cleaning system. If there is a risk of explosion in the material handling process, an inert gas device can be used to prevent the leakage of combustible gas and ensure safety, which meets the requirements of explosion-proof standards.

Advantage of disc centrifuge

The separation factor of disc centrifuge is generally 8000 ~ 20000G. It is usually used to process materials that are difficult to effectively separate by conventional centrifuges, such as highly dispersed liquid-liquid two-phase emulsions, slow-settling liquid-solid two-phase suspension with small solid particles, etc. It can separate suspensions with a solid concentration of less than 3%. The technical parameter range of disc centrifuge is relatively large, and the diameter of the drum is generally 150 ~ 1200 mm. The disc centrifugal separator can provide a better result of separation with a clearer centrate, and can be adopted in more areas with its wide range of technical parameters.

Working Principle of disc centrifuge

Disc centrifuge is a kind of industrial centrifuge used to clarify and separate liquids. It also belongs to vertical centrifuge. Because there is a set of disc-shaped parts (discs) nested together in the drum named disc centrifuge. The drum is driven by a motor through a vertical shaft to rotate at a high speed. The material enters the disc centrifuge drum through the feed pipe, and then enters the disc group. It accelerates in the distribution chamber until synchronized with the speed of the drum. When the suspension (or emulsion) flows through the gap between the discs, the solid particles settle on the discs to form sediment under the action of centrifugal force. The sediment slides along the surface of the disc, then it separates from the disc and accumulates in the part of the drum with the largest diameter - solid slag collection chamber. The solid phase is discharged by controlling the sealing water and slag water, and the separated liquid is discharged from the liquid outlet. The function of the disc is to shorten the settlement distance of solid particles and expand the settlement area of the drum. The installation of the disc in the drum greatly increases the production capacity of the separator.

Application of disc centrifuge

Oil: Clarification and Separation for Vegetable Oil, Animal Oil, Fish Oil, Crude Oil, all kinds of fuel oil and Luge.

Food: Juice Clarification, Beer Separation, Fermented liquid Clarification and Separation.

Pharmaceutical Industry: Extraction for Vaccine, Mycelium, Glucose, Insulin, Antibiotics, Vitamins.

Chemical Industry: Recovery for Dry cleaner solvents, Galvanized liquid, Aluminum sulfate solution, Tar water mixture, PVC,

Polypropylene, Argentum (In the film processing), Catalyst and Magnet.

Traditional Chinese medicine: Clarification and Separation for Plant Extraction

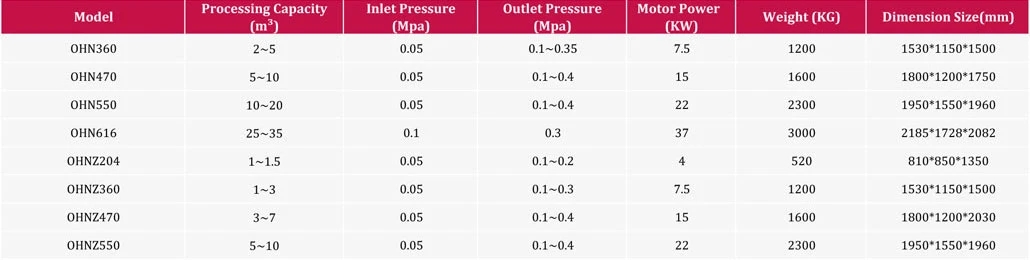

Technical Parameter

The buyers of 3 phase centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing 3 phase centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Biological and environmental centrifuge and an unforgettable experience of partnering with us.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 3 phase centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1