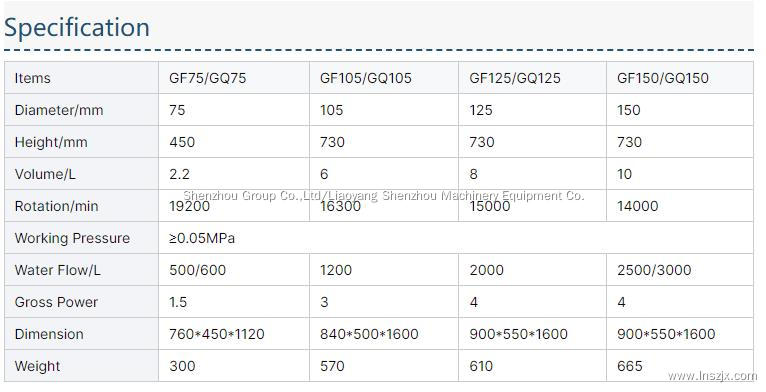

High Speed Spirulina Algae Seaweed Harvest Tubular Centrifuge With Factory Price

GQ SERIES: it is used for separating all kinds of suspension which is difficult to be separated. It is especially suitable for solid-liquid separation with small concentration, high viscosity, fine solid phase particles and small difference in solid-liquid weight. For example, all kinds of liquid , grapes clarification of sugarwash bitide, malic acid, oral liquid and beancurd root; Coal tar, graphite slag removal; Extraction of various proteins, algal bands and pectin; Refining molasses; Blood separation, vaccine mycelium, each settlement of seed glucose; paint, dye, various resins, rubber solution purification.

The Spirulina Tubular Centrifuge - High Speed Separator is designed with precision and efficiency in mind, utilizing advanced technology to separate spirulina effectively. The high-speed separator ensures a smooth and continuous flow, resulting in a higher yield of spirulina extraction. Its compact and durable design makes it an essential tool for any spirulina production facility, offering a quick and efficient solution for processing large quantities of spirulina.

At our company, we serve our customers with the utmost dedication and satisfaction, offering top-of-the-line products like the Spirulina Tubular Centrifuge - High Speed Separator. With its efficient separation capabilities and high-speed operation, this centrifuge ensures optimal performance and productivity in various industrial applications. Our team of experts is committed to providing superior quality products and excellent customer service, catering to the unique needs of each client. Trust us to serve you with professionalism, reliability, and expertise, delivering solutions that exceed your expectations. Choose us for all your centrifuge needs and experience the difference that our exceptional service can make.

At our company, we serve our customers with top-of-the-line equipment, such as the Spirulina Tubular Centrifuge - High Speed Separator. Our main focus is on efficiency and quality, ensuring that your processes run smoothly and effectively. With our high-speed separator, you can expect superior performance and reliable results every time. We are dedicated to providing exceptional service and support to our clients, guiding them through the selection and usage of our products. Trust us to deliver the equipment you need to elevate your operations to the next level. With us, you are in good hands.

Working Principle of Algae Tubular Separator Centrifuge

Tubular Centrifuge consists of machine body, driving part, bowl, liquid collecting tray and liquid inlet bearing seat etc. On top of the bowl is the flexible spindle and at the bottom is the damping floating bearing. The spindle is coupled with driven wheel by buffer on the coupling seat. The motor transmit power to the driven wheel through drive belt and tension wheel, thus for the blow to rotate around its own axis at high speed, to form a strong centrifugal force field. The material is injected inside from the liquid inlet at the bottom, and the centrifugal force compels the clarification liquid to flow upwards along the inner wall of bowl, and the clarification liquid flows out from the outlet. The solid deposit in the bowl and it will be discharged by manual after the machine is shut down.

|  |

| The motor of tubular centrifuge We can provide standard normal motor or explosion-proof motor. Normal power supply is 380V, 50Hz, 3-phase, 2.2kw. Different voltage in different country can be customized. Such as 220V or 415V, 50Hz or 60Hz, 1-phase or 2-phase. |

The Feeding inlet The feeding inlet of raw liquid is at the bottom of machine. All the contact part with raw liquid is stainless steel 304, also stainless steel 316 can be required. The user can use pump or high-low position feeding tank to feed. |  |

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1