In response to the characteristics of xanthan gum, Shenzhou has specially developed a horizontal screw centrifuge for xanthan gum separation.

The Xanthan Gum Horizontal Screw Centrifuge offers efficient separation capabilities, allowing for quick and effective processing of xanthan gum. Its innovative design ensures high levels of productivity and accuracy in separating materials. With a focus on performance and reliability, this centrifuge is a must-have for industrial applications requiring precision separation processes.

With a commitment to innovation and efficiency, our company specializes in the production of high-quality Xanthan Gum Horizontal Screw Centrifuges. Our state-of-the-art technology ensures precise separation of materials, resulting in superior performance and reduced downtime. We take pride in our dedication to customer satisfaction, offering reliable and cost-effective solutions for various industries. With years of experience and a team of experts, we strive to continuously improve our products to meet the evolving needs of our clients. Trust us to provide you with the best centrifuge solutions for your business.

Our company specializes in providing innovative separation solutions for various industries, including the Xanthan Gum Horizontal Screw Centrifuge. With a focus on efficiency and precision, our centrifuge offers unparalleled separation capabilities, ensuring the highest quality end product for our customers. We pride ourselves on our commitment to continuous improvement and customer satisfaction, always striving to deliver reliable and cost-effective solutions. With years of experience in the field, our team of experts is dedicated to providing top-notch service and support to meet our customers' needs. Trust us to deliver exceptional results with our Xanthan Gum Horizontal Screw Centrifuge.

In response to the characteristics of xanthan gum, Shenzhou has specially developed a horizontal screw centrifuge for xanthan gum separation.

Separation is an important step in the production of xanthan gum.

The horizontal screw centrifuge developed by Shenzhou meets the production requirements of xanthan gum and has received unanimous praise from customers for its separation effect.

Pretreatment of raw materials:

After refining primary starch into starch milk, it enters the continuous sterilization gelatinization system to prepare a clear and impurity free starch gelatinization liquid. The nitrogen source is hydrolyzed using soybean cake powder under specific conditions, and then centrifuged to remove the residue to obtain a turbid liquid without visible suspended particles.

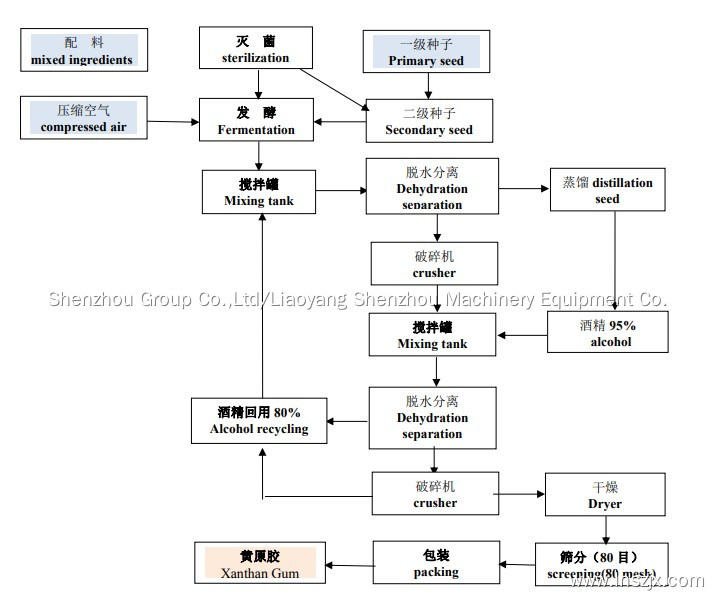

Sterilization: The processed carbon and nitrogen source culture medium is instantaneously heated to 120 ℃ using an automatic continuous sterilization method, maintained for 10 minutes, and then the heat energy of the material is recovered, cooled to the desired temperature.

Strain expansion culture: primary and secondary seed tanks culture for 13 to 18 hours, with a culture temperature of 28 to 30 ℃. They have a large number of cells, a robust body, and evenly stained mature seeds.

Fermentation: After the fermentation tank is empty and cooled to about 30 ℃, the secondary seeds are inoculated into the fermentation tank using differential pressure. The temperature of the fermentation tank is maintained at 28 ℃, and the fermentation time is 60-70 hours with ventilation and stirring.

Extraction and drying: Use alcohol to extract xanthan gum from fermentation broth, wash the mash and alcohol twice in a tank, remove the solvent, press, and enter a vacuum drying device. During the drying process, recover alcohol, and dry to a moisture content of 10-12%.

Packaging: The material is crushed by a pulverizer and made into 80 mesh petroleum grade xanthan gum as required.

Ethanol recovery: Waste ethanol used for elution is distilled in distillation column and then re-entered the system for use

Xanthan gum product quality: Implement petroleum grade quality standard

Xanthan gum product quality: Implement petroleum grade quality standard

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Decanter Centrifuge and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the 2 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 phase centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 2 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing 2 phase centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1