Our disc centrifuge specially used for crude oil separation

Shenzhou disc crude oil Centrifuge is a continuous process centrifuge machine capable of continuously separating Water and Sludge from any oil.

An Industrial Oil Water Centrifuge uses discs in the bowl to magnify the effective g-force, making them highly efficient at separating small traces of water and sludge from oil or the other way around. These centrifuges are also known as Disc Stack Separators.

An oil centrifuge is a standard industrial separation device that finds various uses in various industries, from food and beverage to waste processing to chemical and crude oil production.

With its flow-through design, this centrifuge can continuously separate liquid from liquid and liquids from solids and other liquids.

Working Principle

An oil centrifuge works on the principle of differential settling using a high centrifugal force to separate oil from solid and liquid contaminants. The centrifuge exerts up to 10,000 Gs of force to separate particles as small as 1 micron from the oil. It also separates any immiscible liquid contaminants from the oil.

Benefits (Advantages)

An oil centrifuge offers several advantages over conventional filters and settling methods of separation. The following is a list of the essential advantages of these centrifugal separators.

High Separation Efficiency: With a centrifugal force above 7,000 Gs, the oil centrifuge can separate small particles (0.5 microns) and all free water in a single pass.

Separation of Water and Solids: Oil centrifuges are three-phase separators that separate water and sediment simultaneously.

Compact Size: Oil centrifuges are relatively small for the capacity of oil they can process.

Low Operating Cost: Unlike filters, centrifuges do not need filter media and the related labor and material cost, resulting in considerable savings.

Emulsion Separation: An oil centrifuge can break simple oil in water or water in oil emulsions. However, chemically bonded emulsions need demulsifying chemicals for effective separation.

Consistent Processing Capacity: Unlike filters whose flow capacity diminishes as the pores get blocked, a centrifuge capacity is consistent due to its mechanical separation.

Material of Construction

The main components of an oil centrifuge typically have the following construction material. Depending on the application, some specially built centrifuges may have all stainless steel bowls.

Bowl

Bowl Body, Bowl Hood, Disc Stack - 316L Stainless Steel

Distributor, Top Disc, Cone, Level Ring - Marine Grade Bronze

Frame

Sludge Chute, Bottom Frame - Nodular Cast Iron

Covers - Silumin (Aluminum Alloy)

Types

Shenzhou oil centrifuges are available in different types that are suitable for specific applications. The standard, most commonly used centrifuges are listed below.

Manual Clean

Manual clean oil centrifuges incorporate a design where the liquid phases continuously discharge from the centrifuge. After stopping the centrifuge, the centrifuge retains the separated solids in the bowl for manual extraction.

Automatic Self Clean

An oil centrifuge with an automatic self-clean feature does not require manual extraction of the separated sludge. The centrifuge bowl design allows the centrifuge to eject the separated sludge while still rotating automatically.

The separated oil and water exit the centrifuge continuously while the separated solids intermittently self-eject.

Examples of Applications

The following are examples of real-world oil centrifuge applications.

Lube Oil

All types of lube oil, from steam turbine oil to engine lubricating oil, need purification from fine metal contaminants and occasionally moisture. An oil centrifuge is ideal for processing large volumes of lube oil to a high purity level without filters. Simultaneous removal of water is an added advantage.

Diesel Fuel

Diesel fuel stored in tanks has rust, sediment, and other contaminants along with water from condensation. An oil centrifuge installed in a kidney loop on the storage tank keeps the fuel's solids and liquid contaminants clean.

Fuel Oil

Fuel oil is a common energy source for most power plants, and large marine engines need to be maintained free of contaminants. A fuel oil centrifuge is a reliable separating machine that removes all sludge and water from fuel oil to keep it usable.

Cutting Oil

A wide variety of industries use cutting oil for various metal-forming applications. This oil picks up solid metal particles during processing. It is essential to remove these particles from the oil for its reuse.

An oil centrifuge can separate 0.5-micron metal particles from the oil, thus making the oil reusable and reducing replacement costs.

Oil Centrifuge System Plant Layout

The system consists of 3 steps needed for oil, water, and sludge processing at high capacity.

Pre-Straining Module - separates debris (i.e., rocks, debris, bolts, etc.) from the untreated waste oil.

Decanter Centrifuge Module - to de-sludge the pre-strained oil to separate the bulk of the sludge.

Vertical Disc Centrifuge Module - for oil-water separation and to remove small particles down to 1-micron level.

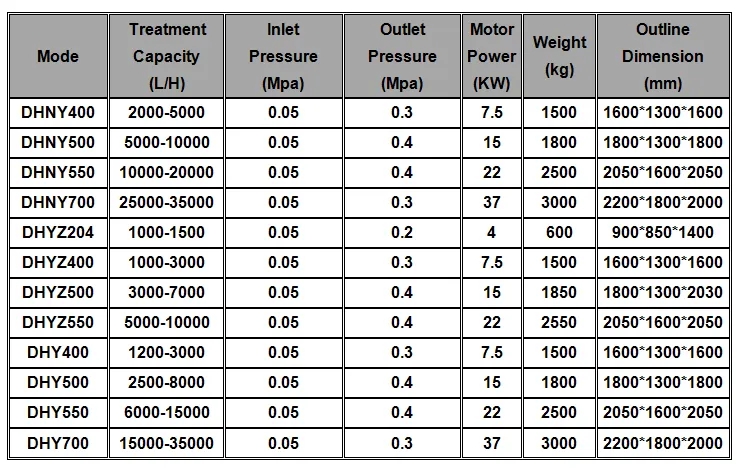

Technical Parameter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1