The oilfield centrifuge is a specialized piece of equipment designed for the drilling industry. Our centrifuge is highly efficient in the separation of unwanted solid materials from drilling fluids, facilitating the reuse of these fluids. Additionally, during the purification of drilling mud, it enables the recovery of valuable barite. This ensures the overall process flow remains intact and provides a reliable sequence of operations. Shenzhou oilfield centrifuges find extensive application in treating oily sludge, managing oily (waste) water, addressing solid waste in drilling oil-based mud, and executing three-phase oil sludge separation systems.

The oil and gas drilling fluid purification horizontal spiral discharge sedimentation centrifuge (LW series frequency conversion centrifuge - dual motor dual frequency conversion type) is a large displacement model developed for high speed and large processing capacity. It is designed for an integrated frame body, which is convenient for on-site installation and lifting; Explosion proof, corrosion proof, weather proof and shock absorption treatment are adopted. Frequency converter and other electrical components are installed in the flameproof cabinet. The flameproof cabinet is equipped with heating and ventilation system, which is suitable for field operation.

The screw pusher is driven by planetary gear reducer, with mechanical and electrical overload protection device, it can realize power transmission of low speed and large torque, and the equipment can be started stably. The equipment has single motor drive, variable frequency dual motor drive, hydraulic drive and other forms, which are selected according to different conditions of users.

The equipment is used for solid particles with diameter ≥ 2 μ The separation of m suspension and the treatment of drilling mud and liquid have high recovery rate and effective solid phase control. It can operate stably for a long time at 0-4000 Rpm speed, and the centrifugal force generated can reach 3180G. The solid control system is used in oil drilling (drilling fluid tail slurry), trenchless, coalbed methane and other fields to remove harmful fine solid particles such as rock cuttings from the mud, or recover valuable weighting materials such as barite, saving costs.

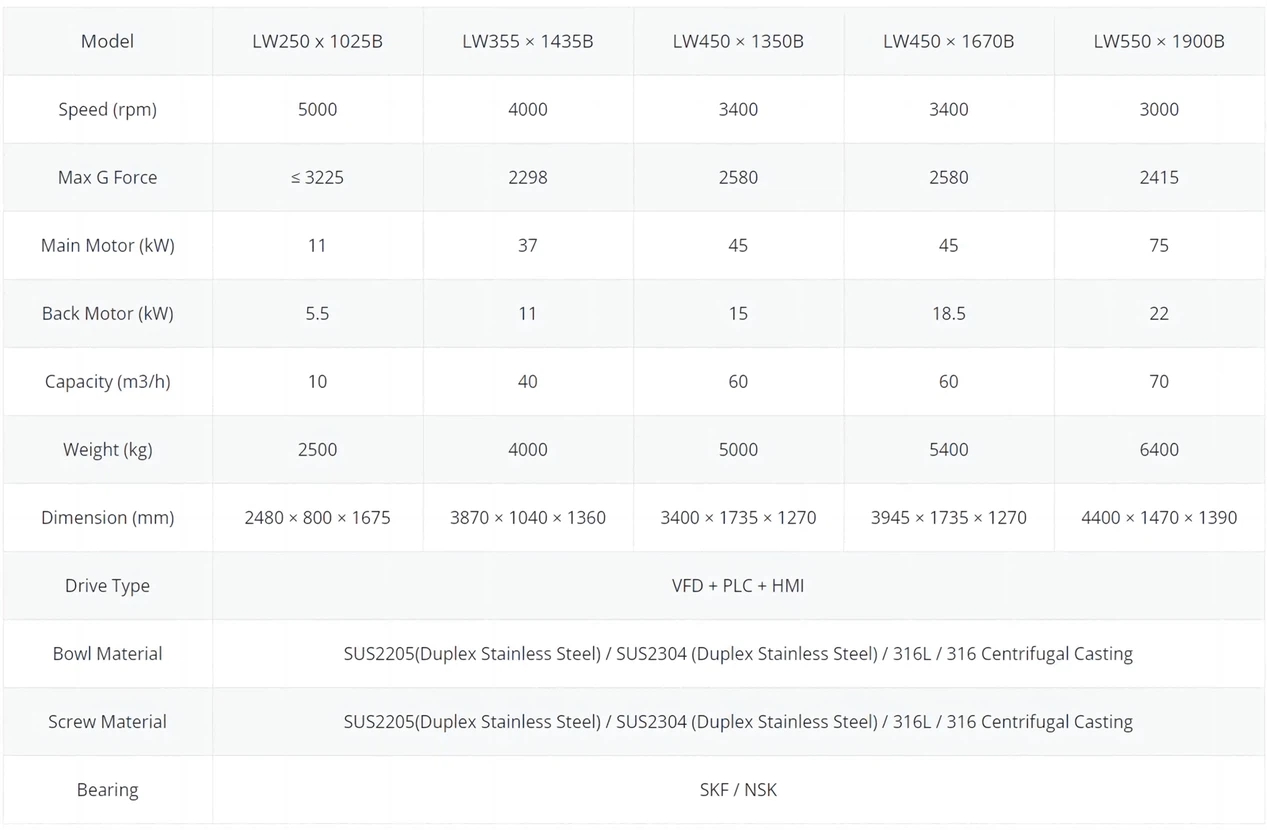

Oilfield Decanter Equipment Parameters

The oilfield decanter centrifuge, a critical piece of separation equipment in the petroleum industry, employs centrifugal force to effectively separate various components within a mixture. It operates at specific RPM (revolutions per minute) settings to generate the necessary centrifugal force, allowing for the separation of components like oil and water. This industrial centrifuge, also known as a solid bowl centrifuge, serves the purpose of efficiently separating different substances in the oilfield, including waste oil, mud, and drilling fluids. Its robust design and high-speed centrifugation process make it ideal for applications in the oil and gas industry, as well as in food processing, chemical industry, and other industrial settings. The centrifuge's operation involves the utilization of centrifugal force to separate solid and liquid phases, and its versatile capabilities cater to a wide range of industrial needs, including barite recovery, dewatering, and purification processes. It comes in various models and capacities, and the choice of centrifuge type and settings depends on specific requirements, such as RPM, G-force, and centrifugation materials. The centrifuge is a valuable piece of equipment, known for its reliability and efficiency in a variety of industries, including the oil and gas sector, where it plays a vital role in separating and purifying different components for further processing.

Customers visited Shenzhou Group :

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1