Our China Honest Supplier Oil Water Tricanter 3 Phase Decanter Centrifuge is the perfect result of combining the perfect performance of all adopted raw materials. Thanks to that, Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge has many great features. Also, it is designed scientifically and reasonably. Its internal structure and external appearance are meticulously designed by our professional designers and technicians. Customers' requirements and tastes can be well satisfied.

Waste Oil Recovery Centrifuge

Product Description

waste oil recovery decanter centrifuges are specially designed to meet the separation requirements of the waste oil processing industry. The waste oil is normal consist of oil water and solids. GN separation equipment offers high performance separation solutions to the 3 phase separation with maximum oil recovery.

The waste oil recovery and treatment include following:

Oil storage tank bottom solids and water and oil

Oily residues, slop oils from oil refineries

Oil sludge lagoons

Oil water mixtures from ship ballasts

API oil water separator sludge treatment

Industry discarded lubricant oils and emulsions

Industrial oil / water and emulsion waste streams

Advantage of waste oil recovery decanter centrifuge from Shenzhou

More sizes available with big length/diameter ratio of 4.2:1 or greater.

High G force up to over 3000 G.

Two phase or 3 phase separation decanter is available.

Nitrogen purged centrifuge for explosion proof.

Duplex Stainless Steel bowl for Corrosion resistant materials

VFD control with HMI and PLC for automatically operation.

Variable bowl speed, differential speed, and adjustable pump capacity for the system.

Various scroll and bowl wear protection systems by tungsten carbide materials.

Customized design with flexibility according to clients requirements.

Worldwide partners and branches to offer you fast support for your waste oil recovery.

Depends on customer's requirements for the source of the waste oil and make-up of the raw material as well as the quality of the products after processing. The selection of equipment and process will be different, but a typical waste oil processing plant will include following.

Separation of solids from the waste oil.

Reducing the viscosity by using chemical or heating.

Breaking the emulsions and make oil, water and solids bound in the emulsion accessible by de-emulsifier dosing for decanter centrifuge separation.

Polymer dosing dewatering to improve the separation efficiency.

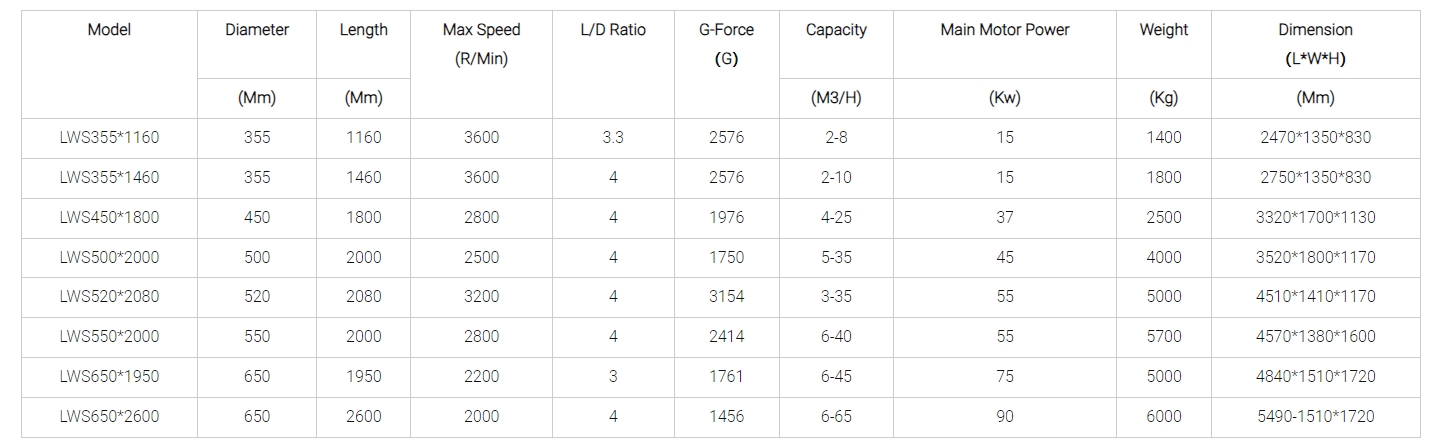

Techinical Parameter

Customers

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1