High-end technologies are utilized to make Disc Rubber Centrifuge Rubber Latex Centrifuge Disc Rubber Latex Centrifuge Separator Machine manufacturing process efficient and labor-saving. It has been found to be very useful in the field(s) of Separation Equipment.

Product Description

The natural latex is from rubber tree, milk white, solid content is 30%~40%, and the average diameter of solid is 1.06um. The fresh natural latex contain latex 27%~41.3%(m/m), water 44%~70%, protein 0.2-4.5%, natural resin 2%~5% ,saccharides 0.36%~4.2% and ash 0.4% . To facilitate transportation and processing, natural rubber latex should be concentrated to the solid content of 60% by adopting the method of centrifugal centrifugal or evaporation. So it also known as concentrated latex.

Latex series disc separator is good equipment for producing latex. It is mainly used for natural rubber slurry concentration and clarification, makes rubber slurry separate concentrated latex and clear skim latex, and eliminates the solid impurity of whey liquid. Separator’s design, manufacture and checking and acceptance comply with national standard GB10897 and GB10898.

Rubber latex centrifuge machine

Product Description

Drive structure support use SKF bearing, by employing optimal design to reduce the height of the drum’s center of gravity. It can effectively lower the vibrational level of the whole separator, improve the reliability of the equipment and increase the stability of the separator.

Product Description product feature of latex separarator centrifuge

1.Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise

and vibration, the installation path is very easy to operate.

2.The bearings use imported FAG, transducer using Japan brand “ Fuji”, the main strengthen parts of Roller body and Roller cover use 2Cr13,and the other parts of contacted materials such as Disc all use 304L.

3.The Stainless steel cover use SUS304

4.The base use casting steel, coating does the same way as ship bottom.

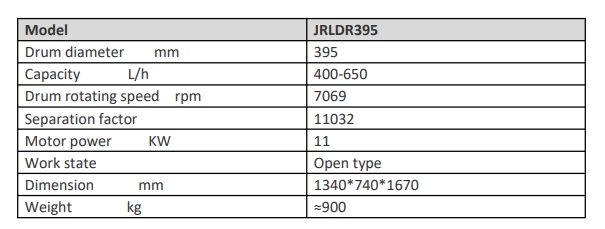

Technical Parameter

Service from Shenzhou

Pre-Service

1. 24 hours online consult and service

2. Introduce the details of products to the customers, answer the question raised by customer at firstly;

3. Providing the operation , installation and working video for customers.

4. Providing the different solutions for choice according to the needs and requirements of customers;

Sale Service

1. Ensure new product with high quality before delivery;

2. Packing according to the export requirements and shiping carefully;

3. Provide full set of documents as customer’s requirements.

4. Providing one year sparing parts for you for free.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1