Taking advantage of the principle that the light liquid, heavy liquid, and solid phase, with different density and mutually insoluble in the mixed liquid, gain different sedimentation speed in the centrifugal force field or gravity force field, separating stratification or causing the solid particles in the liquid to deposit can be achieved.

In the gravity force field or centrifugal force field, the light liquid phase, the heavy liquid phase, and the solid phase with different density and mutually insoluble in the mixed liquid, respectively gain different sedimentation speed, and thus separate and stratify. In the gravity force field, it is called gravity separation, while in the centrifugal force field it is called centrifugal separation.

About Shenzhou

Brief Introduction:

Taking advantage of the principle that the light liquid, heavy liquid, and solid phase, with different density and mutually insoluble in the mixed liquid, gain different sedimentation speed in the centrifugal force field or gravity force field, separating stratification or causing the solid particles in the liquid to deposit can be achieved.

In the gravity force field or centrifugal force field, the light liquid phase, the heavy liquid phase, and the solid phase with different density and mutually insoluble in the mixed liquid, respectively gain different sedimentation speed, and thus separate and stratify. In the gravity force field, it is called gravity separation, while in the centrifugal force field it is called centrifugal separation.

Featuers

compact structure

continuous operation

smooth running

strong adaptability to the separation material

large handling capacity

convenient maintenance

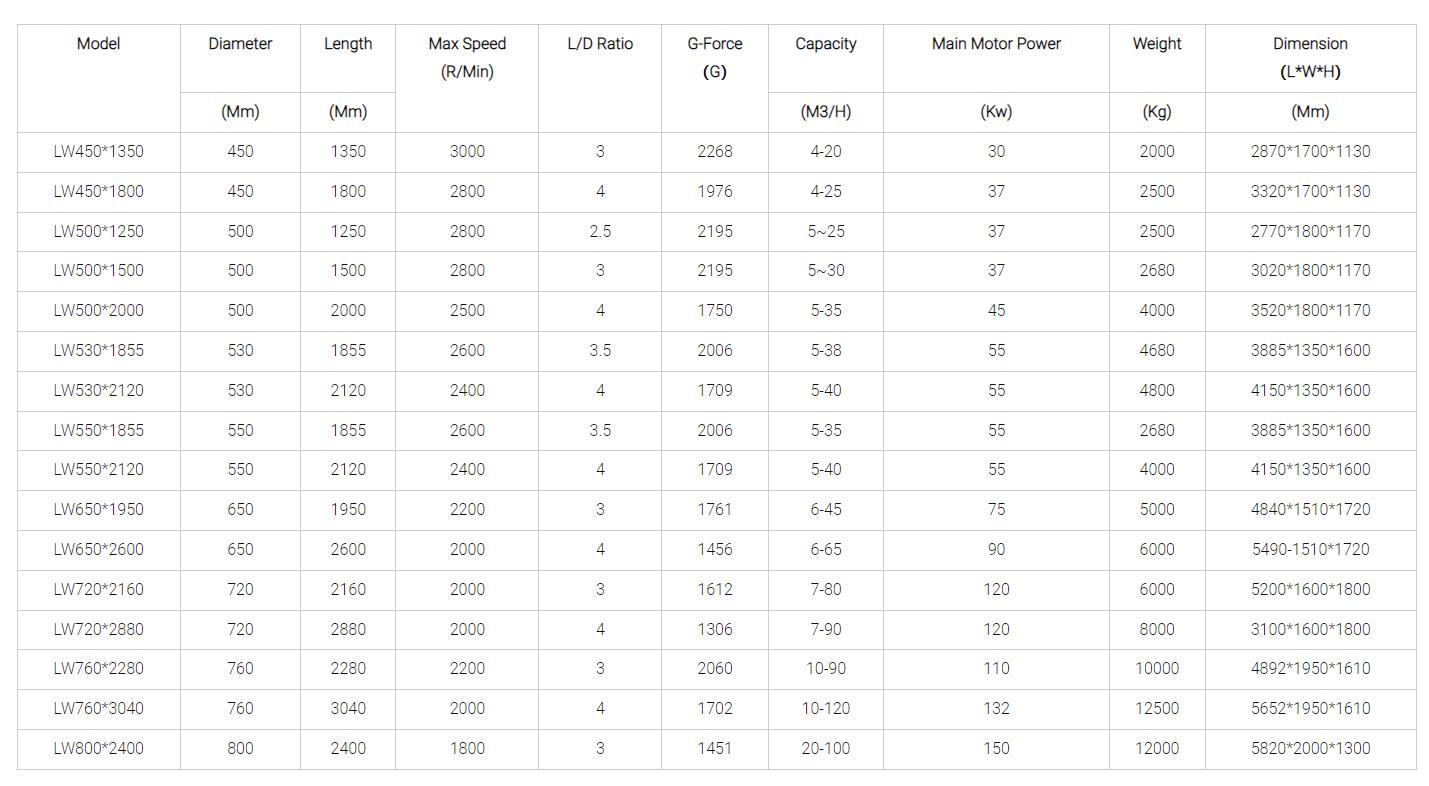

Technical Paramter:

Company Advantage

We have always followed the standardization rules for a rigorous production process, saving time and cost for both parties and bringing maximum benefits to you.

Application

Wastewater Treatment:

• Sludge dewatering.

• Municipal and industrial wastewater treatment.

Oil And Gas Industry:

• Separation of oil, water, and solids in drilling mud.

• Recovery of drilling fluids.

• Oil and gas processing for solids removal.

Chemical Processing:

• Clarification of chemical suspensions.

• Separation of fine particles and liquids.

• Solids-liquid separation in chemical manufacturing.

Food And Beverage:

• Clarification and purification of beverages.

• Separation of solids from food processing liquids.

Pharmaceuticals And Biotechnology:

• Bioprocessing applications.

• Clarification and purification of pharmaceutical products.

Mining And Minerals:

• Separation of valuable minerals from ore.

• Tailings dewatering.

Environmental Remediation:

• Treatment of contaminated groundwater.

• Soil washing and remediation.

Pulp And Paper Industry:

• Removal of fine solids from pulping processes.

• Recovery of fibers from paper mill effluents.

Chemical And Petrochemical:

• Solids-liquid separation in chemical and petrochemical plants.

• Removal of impurities from process streams.

Biomass And Renewable Energy:

• Processing biomass for biofuels.

• Separation of algae and biomass in renewable energy production.

Mining And Drilling:

• Solid-liquid separation in mining operations.

• Drilling fluid recovery in oil exploration.

Paints And Coatings:

• Clarification and purification of paint and coating formulations.

• Removal of solids from paint manufacturing processes.

Dairy Industry:

• Separation of milk and cream.

• Whey processing.

Textile Industry:

• Separation of dyestuffs and pigments.

• Wastewater treatment in textile processing.

Biodiesel Production:

• Separation of glycerol and biodiesel.

• Clarification of biodiesel feedstock.

Products Packaging

Packaging:

1. Customized Crate: The Decanter Centrifuge is meticulously packed in a custom-made wooden crate that is specifically designed to withstand the rigors of long-distance transportation. The crate is constructed using high-quality, robust lumber to provide maximum protection.

2. Internal Cushioning: Inside the crate, the Decanter Centrifuge is surrounded by a layer of dense foam padding. This cushioning material is carefully selected to absorb shocks and vibrations during transit, safeguarding the equipment from any potential damage.

3. Component Protection: Fragile or sensitive components are given additional protection through the use of bubble wrap or foam inserts, ensuring their integrity upon arrival.

4. Secure Fastening: To prevent any movement or shifting during transit, the equipment is securely fastened within the crate using heavy-duty straps and fasteners.

5. Labeling: Each crate is prominently labeled with essential information, including the equipment name, serial number, handling instructions, and clear directional arrows indicating the upright position.

Transportation:

1. Optimal Transport Mode: We select the most appropriate transportation method based on your location and delivery timeline. Whether it be by truck, sea freight, or air cargo, rest assured that our choice is made with the aim of ensuring timely and safe delivery.

2. Professional Handling: During loading and unloading, experienced and trained personnel use specialized lifting equipment such as cranes or forklifts to guarantee careful and damage-free handling.

3. Climate Control: For international shipments, we take climate control measures when necessary to protect sensitive components from extreme temperatures and humidity, ensuring the equipment's longevity.

4. Comprehensive Documentation: All required customs documentation, including detailed invoices, packing lists, and any necessary import/export permits, are meticulously prepared and included with the shipment to facilitate smooth customs clearance processes.

5. Insurance Coverage: Adequate insurance coverage is arranged to safeguard against unforeseen circumstances during transit, providing you with peace of mind.

6. Tracking And Communication: We provide a reliable tracking system that allows you to monitor the progress of your shipment in real-time. Our team remains in constant communication with you to address any questions or concerns promptly.

Our Service

Experienced Staffs

Rich experience in production.Good word-of-mouth, widely praised by customers!

Quality Control

We have the authority certificate of quality and safety, all in accordance with international quality standards.

Fast High Quality Service

The company with a good quality of products and quality service has won praise majority of customers.

Hot Tags: chemical wastewater centrifuge, China chemical wastewater centrifuge manufacturers, suppliers, factory, Centrifuge concentration treatment, Ethanol production centrifuge, Beer Yeast Separator, Celery juice separation, Industrial Large Capacity Centrifuge, solid liquid separation equipment.

Customers from other countries visited shenzhou group

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1