Treatment of sand and gravel washing water

Save up to 90% on water costs while meeting strict environmental regulations

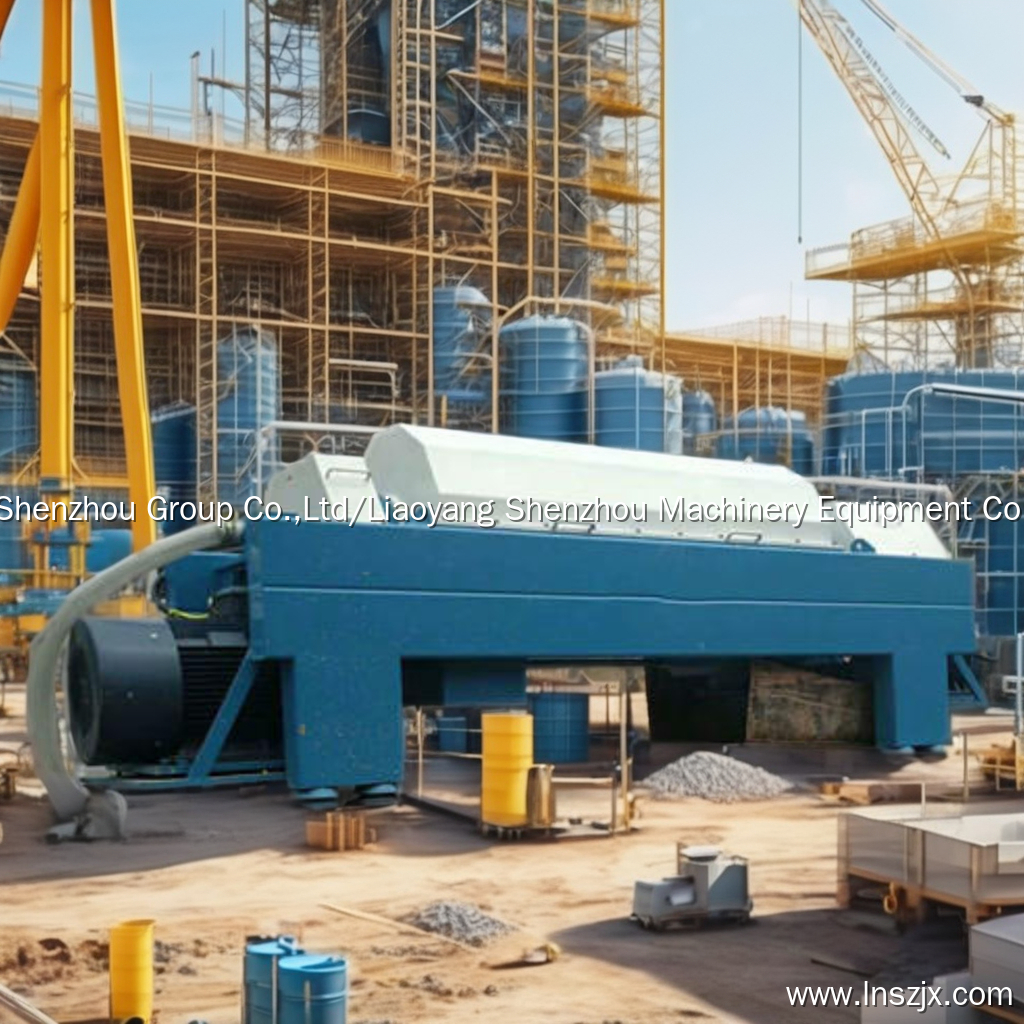

High-performance centrifuge system eliminates need for costly settling ponds

Automated 24/7 operation with advanced wear protection for maximum uptime

Reduce the need for fresh water by 90%

Decanter centrifuges for recovery of wash water in sand and gravel mills.

Sustainable use of water as a resource and stronger regulations call for an intelligent and simple solution to recycle existing process water. When treating sand and gravel, industrial centrifuges drain the sludge from wet treatment. The reclaimed water can then be returned to the process.

Recycle water directly

Decanter centrifuges for sludge dewatering separate the fine solids from the water. The clear water can be stored in a washing water reservoir and is immediately available to the washing process again. There is no need to maintain sedimentation ponds that require a lot of space and expensive excavations.

Decanter centrifuges have a wide range of applications in mines, which are mainly reflected in the following aspects: Tailings dewatering: A large amount of tailings are generated during the mining process. Decanter centrifuges can efficiently dewater the tailings slurry, reducing the moisture content of the tailings. This facilitates subsequent transportation and stacking, reduces the environmental pollution caused by tailings, and can also recover part of the water resources in them, achieving the recycling of resources. Slurry concentration: In the mineral processing technology, it is necessary to concentrate the slurry to improve the processing efficiency of subsequent mineral processing equipment. Through the action of centrifugal force, the decanter centrifuge can quickly separate the solid particles from the liquid in the slurry, concentrating the slurry and providing a suitable slurry concentration for subsequent separation operations. Concentrate dewatering: The concentrates obtained through mineral processing usually contain a relatively high moisture content and need to be dewatered to meet the requirements of subsequent processes such as smelting. The decanter centrifuge can perform deep dewatering on the concentrates, reducing the moisture content of the concentrates, improving the quality and value of the concentrates, and also reducing the transportation cost. Wastewater treatment: A large amount of wastewater containing various pollutants such as heavy - metal ions and suspended solids is generated during the mine production process. The decanter centrifuge can be used for the pretreatment of mine wastewater. By separating the solid particles in the wastewater, it reduces the suspended solids content of the wastewater, creating conditions for the subsequent in - depth treatment of wastewater and contributing to the standard - compliant discharge or reuse of mine wastewater.

|  |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1