Best Solid-bowl Centrifugal Decanters Supplier

Our decanter can be used to thicken the sludge, dewater the sludge or thicken-dewater the sludge. The whole sludge dewatering system has five parts:

1) Sludge Feeding System

2) Polymer Make-up System

3) Thickening and Dewatering system

4) Solid Conveying System

5) Electric Control System of Complete Set

We configure different electric control system for different customer needs:

1) Simple Type: Able to control automatically during operation

2) General Type: Have PLC control

3) Intelligent Type: PLC+PC Control, have data sampling and output

Main Characters of Our Sludge Dewatering Centrifuge with Bigger Length/Diameter Ratio

1)Length/Diameter Ratio L/D≥4.3.High rotating speed and low differential speed system is adopted. Bigger length to diameter ratio increases the resident time of the mixture inside the bowl so that the time for liquid clarifying and solid dewatering is prolonged. High rotation speed generates great centrifugal force. Small differential speed reduces the stirring of screw to the solid. With the increased residence time, good efficiency for dewatering the sludge and clarifying the centrate is achieved. Comparing with typical decanter centrifuges, drier solid cake and clearer centrate is produced by this kind of machine.

2)Big torque hydraulic backdrive is adopted. This provides bigger drive torque. (If the size is the same, the drive torque of hydraulic backdrive is 2 to 4 times of that of mechanical gearbox.)

3)Hydraulic differential speed system is adopted. The output torque is greater (≥16000Nm). The differential speed changes with the load. The differential speed is adjusted automatically through feedback. The discharge power is automatically compensated. In this way, the solid inside the bowl is compacted under the centrifugal force. Moreover, The solid is extruded between the screw blades in the conical section of the bowl. In this way, the discharged solid maintains a invariable dryness and the solid is more dryer. When solid is discharged out of the bowl , the differential speed automatically comes back to its original value. The solid bowl is almost free of clogging. If the throughput is the same, 30% chemical and electricity consumption can be saved by using our decanter. The noise is lower than 84dB.

4)Wide adjustment range of starting differential speed: the differential speed is adjusted within the range from 0 to 20 rpm.

5)Super hard abrasive-resistant material W2C-65% is spay welded on solid discharge port, feed port and conveyor blade. The thickness if 2~3mm. Comparing to tiles, it has better duration and needs no replacement. This prolongs the operation life.

Working Principle of High Dryness Decanter

•

Working Procedure

High dryness decanter can use limit space to fit together different stages of separation.

•

Mixing and Accelerating Stage

Sludge and chemical mixes in the specially designed feed chamber and accelerates together. This prepares the sludge for best separation.

•

Clarifying Stage

The flocculants sediments inside the bowl under centrifugal force, the clear liquid flows out of the weir at the end of the bowl.

•

Pressing Stage

Conveyor pushes the solid toward the discharge end. The sludge is further pressed by centrifugal force and the water comes out of the small holes of the sludge.

•

Double-direction Pressing Stage

In the conical part of the bowl wall, the sludge is pressed by specially designed double direction pressing effect. The specially designed conveyor produces axial pressing force and water comes out of the tiny holes of the sludge.

•

Control the Staying Time of Solid

In order to achieve best dewatering effect when flow rate or character of sludge changes, the solid content inside the bowl should be continuously controlled.This is controlled by the drive system of the conveyor. The drive system of the conveyor can measure real-time the solid content inside the bowl and adjust automatically, solid discharge torque automatically compensated.

•

Drive Technology

The reliable and excellent operation needs good cooperation of bowl drive and conveyor drive. Shanghai Centrifuge Institute researches good drive combination, which can be recommended as best design to suit different applications.

Bowl Drive System

Alternatives includes: - AC Motor + Frequency Converter

- AC Motor + Hydraulic Coupling

- Other Special Ways

Conveyor Drive System

Alternatives includes:

-

Frequency converter back of forward drive

DVF multi-level planet control

-

Hydraulic motor with individual hydraulic pump

-

Other Special Ways

Introduction

Sludge dehydrator-horizontal solid bowl decanter, is key equipment of sludge dewatering unit. It uses centrifugal force to sediment solid content in the mixture. It is fit for liquid solid separation of suspension liquid with solid particle equipment diameter≥3μm, solid liquid density difference ≥0.5g/cm3,and weight concentration ≤10% or volume concentration ≤70%.

Our product includes 9 series (LW220, LW300, LW400,LW450, LW530, LW650, LW760, and LW900)of more than 100 machine types.

The machine can also be sorted by bowl type, such as thickening, dewatering, classifying, clarifying and etc, to fit different kinds of separation.

Our institute can also design, configure and manufacture different equipment. The Mobile sludge dewatering truck can also perform test on customer site. Customers are also welcomed to bring sample to our institute for testing.

In recent years, our company has been cooperating with world-famous centrifuge company. SCL has developed decanter series with bigger length/diameter ratio. The sedimentation zone of bowl of this decanter series is longer and the separation effect is enhanced. For more than seven years, this decanter series has been exported to developed countries in Europe and America.

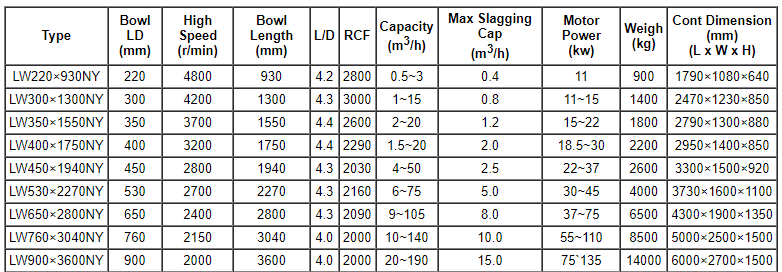

High Dryness Solid Bowl Decanter Specifications

Notes:

1.Actual capacity depends on character of mixture and treatment requirement.

2.Maximum solid discharge capacity is calculated assuming that the differential speed is 10r/min and the sludge is pressed in two directions.

3.Sludge feed concentration range is 0.5~0.6%.

4.Parts contacting the mixture are made from AISI321 or AISI316 stainless steel.

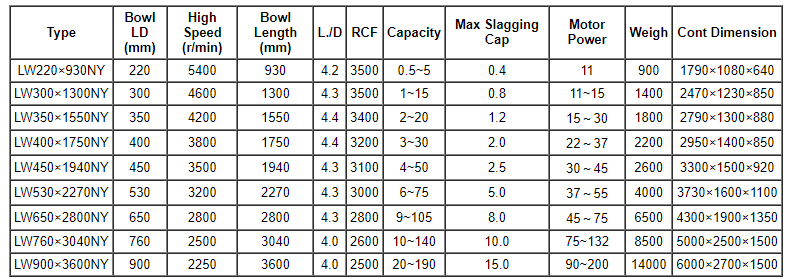

High Speed High Dryness Solid Bowl Decanter Specifications

Notes:

1.Actual capacity is related to character of mixture and treatment requirement.

2.Maximum solid discharge capacity is calculated assuming that the differential speed is 10r/min and the sludge is pressed in two directions.

3.Sludge feed concentration range is 0.5~0.6%.

4.Bowl material of above centrifuges is AISI329 stainless steel (centrifugally cast). Parts contacting the mixture are made from AISI321 or AISI316 stainless steel.

here are three types of the control system of Shenzhou sludge dewatering complete equipment.

1)Simple Control System

This kind of control system is composed of ordinary electric components. It can operate separation machine system, feed system, chemical adding and throwing system automatically / manually. It can also monitor operation of main equipments, alarm troubles and is protected by interlink. This system can meet the need to control complete set for single machine.

2)PLC Control System

It is well-known that PLC is widely used in industrial auto control system, because of its stable operation, resistance to disturbing, safety operation, easy configuration and software programming. SCI developed PLC Control System for sludge dewatering complete to fit for the complicated treatment and high requirements from sludge dewatering. It can automatically adjust the differential speed and feed flow rate. This control system is highly automated. It can operate the factory without human. It can display many specifications and has more than 30 kinds of trouble monitoring, alarming and protecting functions for equipment operation. This will make the whole working system safer and more reliable.

3)PLC Controller + PLC Control System

The above-mentioned PLC Control system can communicate with the central control room PC through network by means of communication interface to on-site PC or network communication system demanded by customer.

1) Able to control automatically as above-mentioned PLC control system;

2) Able to monitor dynamically the sludge dewatering on the PC screen, the working conditions of all the equipments and other related specifications are displayed as figures;

3) Able to draw the history trend curve of specifications;

4) Able to display and print report form for a day, a month or a year;

5) The on-site PC and central control upstream computer can monitor the working status of several sets of sludge dewatering equipments. It can also remote control the starting or stopping of each sludge dewatering set.

6) To avoid unauthorized person from entering the system, it has setting functions in three levels.

Paramters: