A horizontal screw centrifuge is a spiral discharge settling centrifuge. It mainly consists of a high-speed drum, a screw conveyor with a hollow shaft that rotates in the same direction as the drum and has a lower speed ratio than the drum, and a differential. When the suspension to be separated is sent into the drum by the hollow shaft, it is immediately thrown into the drum cavity under the centrifugal force generated by high-speed rotation. The high-speed rotating drum generates strong centrifugal force, which throws solid particles with higher density than the liquid phase onto the inner wall of the drum, forming a solid layer (called a solid ring layer due to its ring shape); Due to its low density and centrifugal force, water can only form a liquid layer inside the solid ring layer, known as the liquid ring layer. Due to the different rotational speeds of the spiral and the drum, there is a relative motion (i.e. speed difference) between the two. The relative motion between the spiral and the drum is used to slowly push the sludge in the solid ring layer to the cone end of the drum, and after passing through the drying zone, it is continuously discharged through the outlet distributed around the circumference of the drum; The liquid in the liquid ring layer is continuously 'overflowed' by gravity from the weir to the outside of the drum, forming a separated liquid.

A horizontal screw centrifuge is a spiral discharge settling centrifuge. It mainly consists of a high-speed drum, a screw conveyor with a hollow shaft that rotates in the same direction as the drum and has a lower speed ratio than the drum, and a differential. When the suspension to be separated is sent into the drum by the hollow shaft, it is immediately thrown into the drum cavity under the centrifugal force generated by high-speed rotation. The high-speed rotating drum generates strong centrifugal force, which throws solid particles with higher density than the liquid phase onto the inner wall of the drum, forming a solid layer (called a solid ring layer due to its ring shape); Due to its low density and centrifugal force, water can only form a liquid layer inside the solid ring layer, known as the liquid ring layer. Due to the different rotational speeds of the spiral and the drum, there is a relative motion (i.e. speed difference) between the two. The relative motion between the spiral and the drum is used to slowly push the sludge in the solid ring layer to the cone end of the drum, and after passing through the drying zone, it is continuously discharged through the outlet distributed around the circumference of the drum; The liquid in the liquid ring layer is continuously 'overflowed' by gravity from the weir to the outside of the drum, forming a separated liquid.

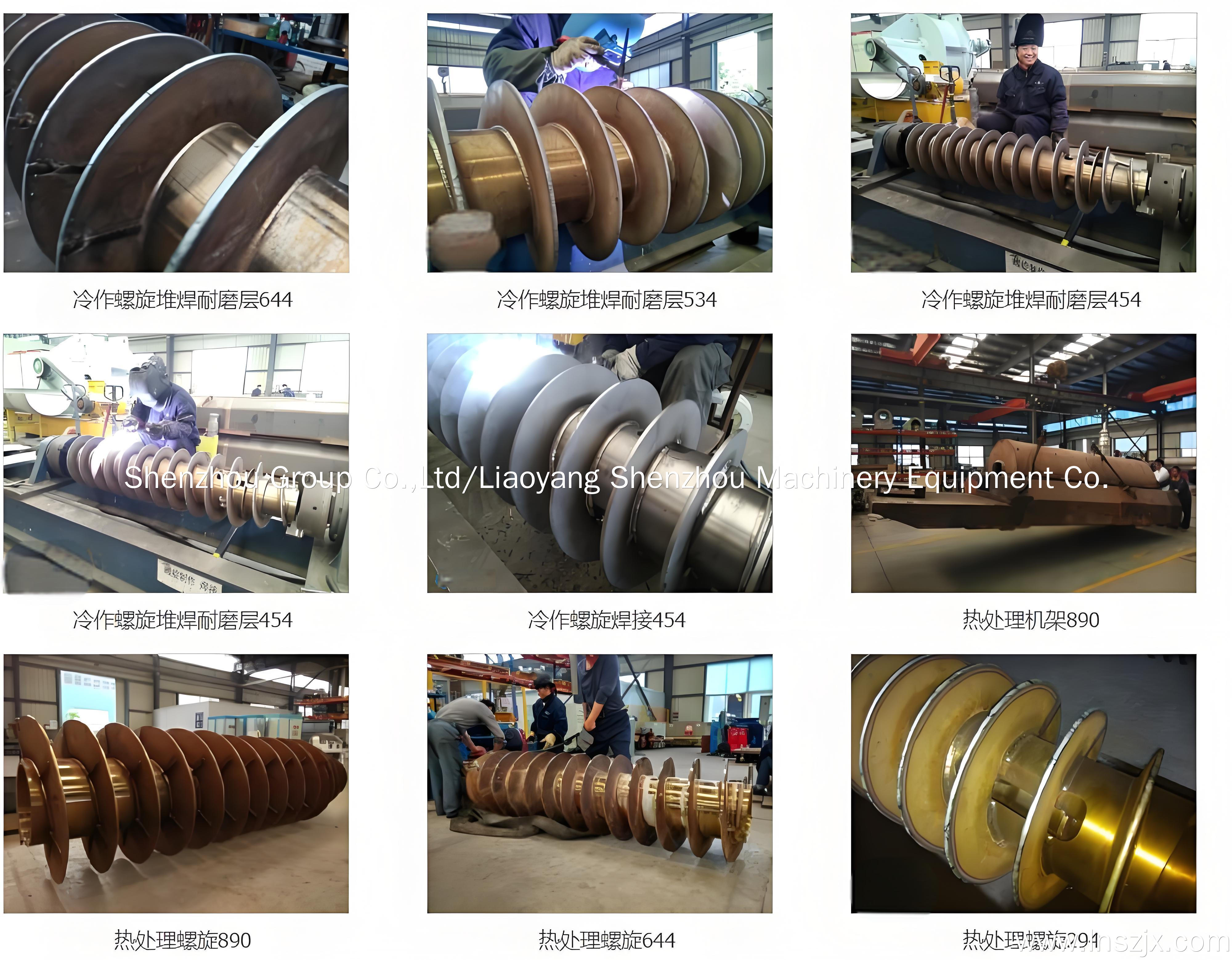

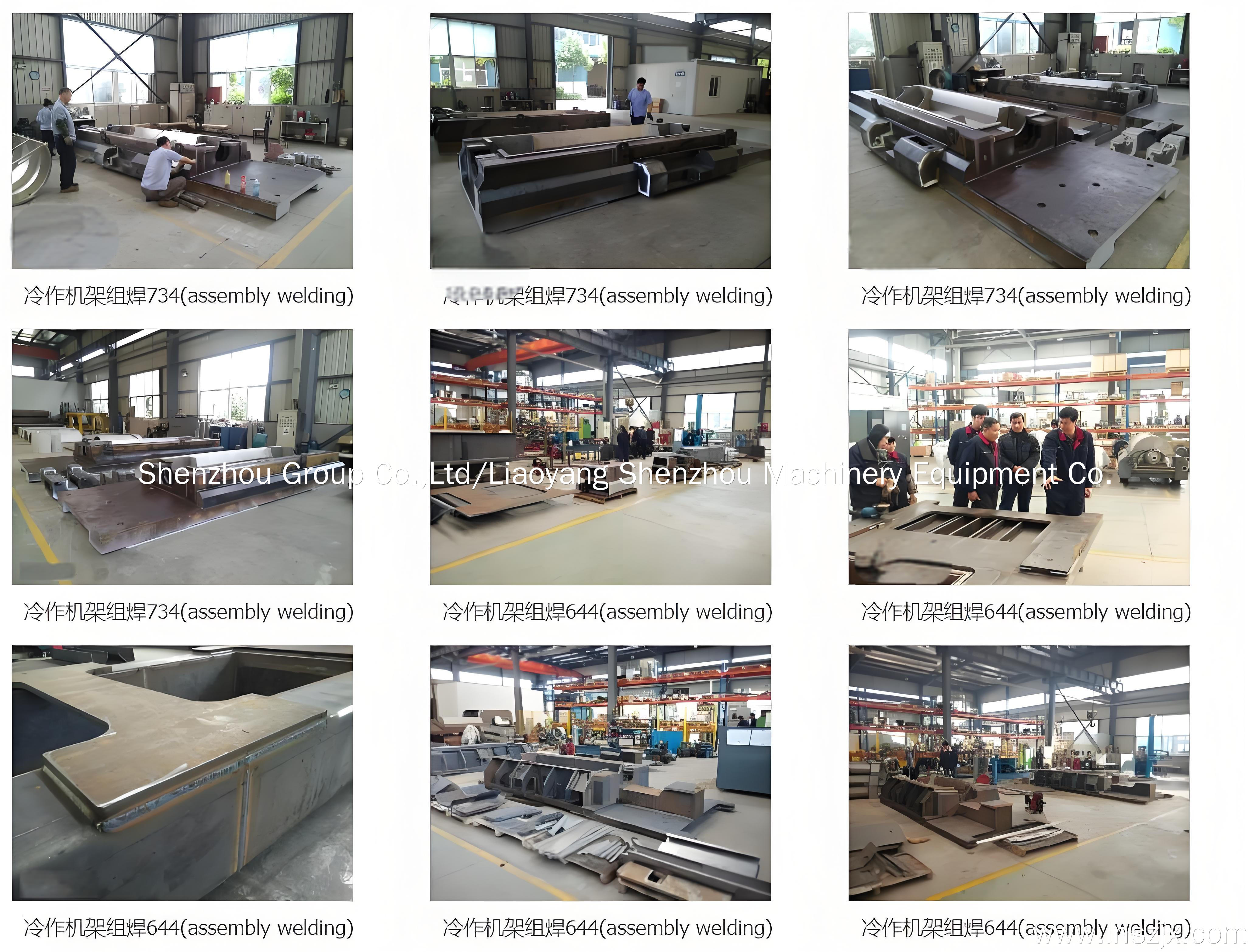

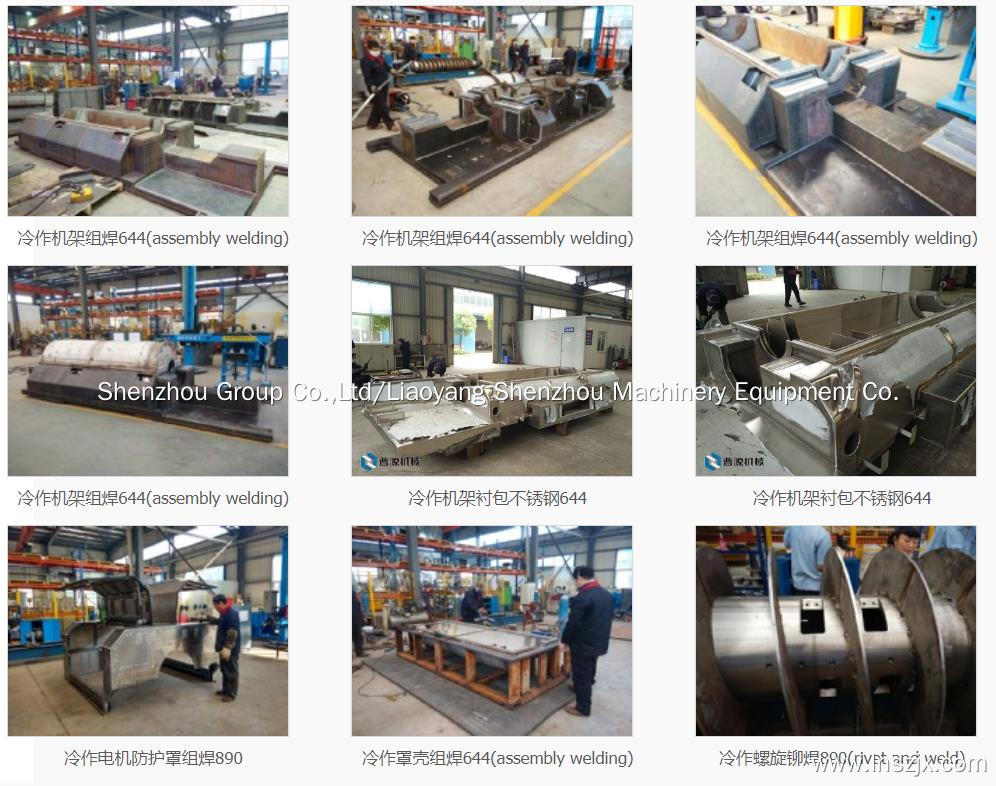

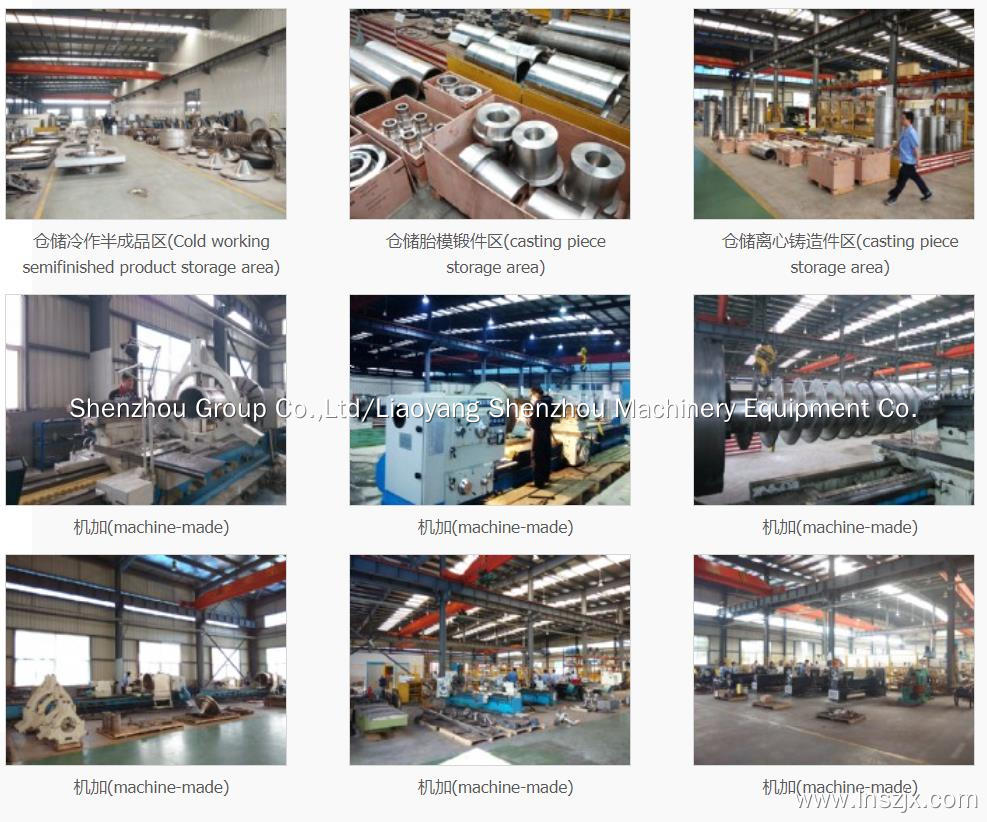

The horizontal screw centrifuge consists of a frame, hood, main bearings, drum, screw, differential, drive system, control system, and safety protection system. The drum and the screw rotate at high speed in the same direction with differential speed. The material enters the inner cylinder of the screw through the feeding pipe and enters the drum through the feeding port.

Under the action of centrifugal force, heavier solid materials deposit on the drum wall to form a sediment layer. The spiral continuously pushes the deposited solid materials to the cone end of the drum and discharges them out of the machine through the slag discharge outlet. The lighter liquid phase material forms an inner liquid ring, which continuously overflows from the large end overflow port of the drum and is discharged outside the machine through the discharge port.

The rotary drum is a key component of a horizontal screw centrifuge, which not only bears the centrifugal pressure exerted by materials and accessories during high-speed rotation, but also the centrifugal force generated by the mass of the rotary drum itself. The spiral conveyor can continuously transport sediment to the discharge outlet outside the machine. Depending on the solid-liquid ratio of the processed material, the ratio of the infusion channel to the slag discharge channel can be 1B1 or 1B2.

The differential speed between the screw of the hydraulic motor and the drum is achieved by the hydraulic motor. The oil supply of the hydraulic motor can be automatically adjusted through an oil transfer joint. Due to the hydraulic transmission and hydraulic station design of the horizontal screw centrifuge, and the drum speed usually being around 3000r/min, it is considered to use thin oil lubrication. The lubricating oil is supplied in a circulating manner, which not only lubricates but also cools the bearings.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1