decanters for fruit and vegetable juices

Decanter centrifuges are ideal for industries where delicate food and beverage products are processed – and where easy cleaning is crucial.

The 2 Phase Decanter Centrifuge for Fruit Juice Optimization offers efficient separation of fruit juice and solids, ensuring a high-quality end product. With its advanced technology, this centrifuge can optimize the juice extraction process, maximizing yield and reducing waste. Its robust construction and user-friendly design make it a reliable and easy-to-use solution for fruit juice producers.

Team strength is at the heart of our 2 Phase Decanter Centrifuge for Fruit Juice Optimization. Our expert team of engineers and technicians have worked tirelessly to design a centrifuge that maximizes efficiency and productivity in fruit juice processing. With years of experience and a deep understanding of the industry, our team has created a product that delivers unmatched results in terms of speed, precision, and quality. By leveraging the collective expertise of our team, we have developed a centrifuge that sets a new standard for fruit juice optimization, making it the ideal choice for businesses looking to streamline their production processes.

Our team of experts at Fruit Juice Optimization is dedicated to bringing you the best quality 2 Phase Decanter Centrifuge for optimizing your fruit juice production process. With years of experience in the industry and a passion for innovation, our team ensures that each product is crafted with precision and excellence. From the design phase to testing and final production, each member of our team brings a unique set of skills and expertise to the table, resulting in a top-of-the-line centrifuge that will revolutionize your juice production process. Trust in our team's strength to deliver the best solution for your business.

decanters for fruit and vegetable juices

Whether you want to use the disk separator to remove pulp from the fruit juices and to clarify them, or to gain vegetable juice through the use of centrifugal decanters or in order to clear waste water from the fruit and vegetable juice production for clearing and concentrating purposes — there are plenty of applications in the vegetable and fruit juice industry. Today, it would be unthinkable to operate a production without centrifuges.

Centrifugal separator with unparalleled efficiency and easy cleaning

Higher juice extraction yield, drier cake and clearer liquid

Easy and fast cleaning with CIP .

High operational flexibility to adapt to different processes or fruits

Wide range of available decanter size all with premium G-Force level

shenzhou is designed to minimize separation costs while delivering a high quality end product. The design is ideal for the manufacture of beverages and viscous foods. The drive system offers much lower power consumption than alternative technologies. The innovative control system reduces operating costs while giving you better control over the separation process.

How does the decanter centrifuge work:

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. A stationary inlet tube introduces the product into the bowl, and a distributor gradually accelerates it. Centrifugal forces separate solids from the liquid. The solids are collected and compacted on the bowl wall.

A conveyor rotates inside the bowl at a slightly different speed. This transports the settled solids on the bowl wall towards the conical end. SHENZHOU's design increases hydraulic pressure inside the drum to improve flow through a narrow opening. The compacted and dewatered solids leave the bowl via discharge openings at the smaller diameter of the conical end. Separation takes place in the entire length of the cylindrical part of the bowl, and the clarified liquid leaves through a paring disc (internal centripetal pump).

All wetted parts in decanter centrifuges for the food industry are made with stainless steel. The control system is equipped with a graphic user interface and multiple communication options.

Decanter Helps Optimize Fruit Juice Concentrate Process

Moving to a new style of decanter largely because of maintenance issues with older machines, a fruit processor found several ways the new system improved production, including sanitation and flexibility.

Decanters, used to extract finely solubilized fruit, are an important part of the juice concentrate process. “We bring the fruit into the plant, inspect it, it gets milled into the consistency of apple sauce, we depectinize it, and then we run it through decanters to pull out the solids,” explains Brian Curtis, plant manager at the Prosser facility.

Decanters separate fruit solids from liquids in Tree Top’s production of juice and juice concentrates.

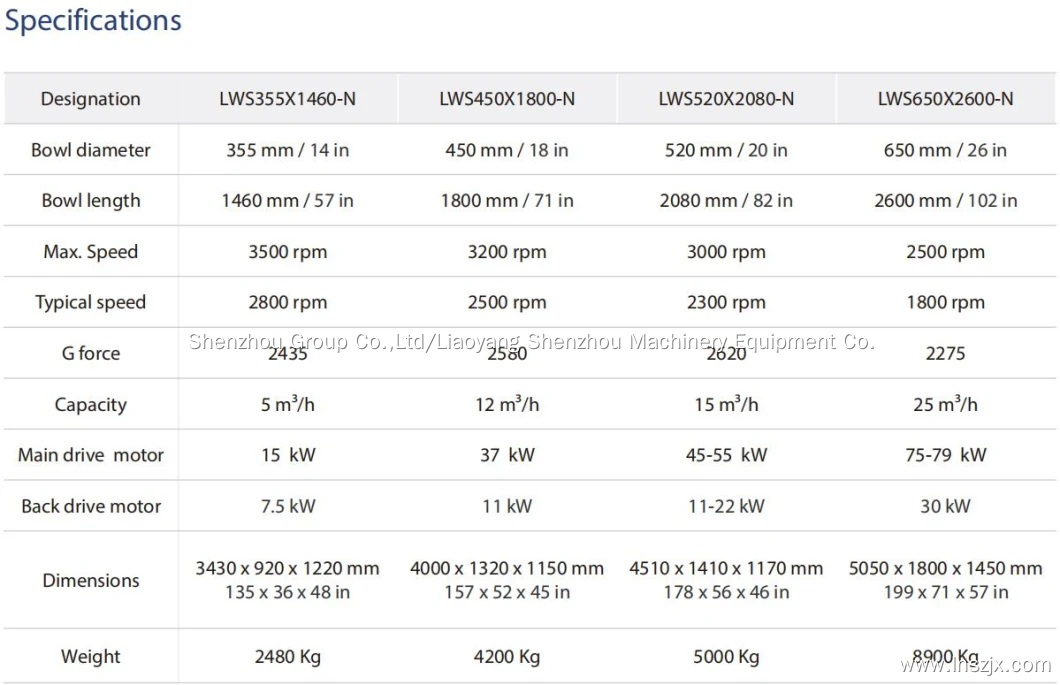

Technical Parameters:

Regarding the attributes and functionality of the 2 phase decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Drying & granulator Machinery and an unforgettable experience of partnering with us.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In essence, a long-standing 2 phase decanter centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the 2 phase decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 phase decanter centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1