2 Phase Decanter Centrifuge from Shenzhou China

2 Phase Decanter Centrifuge

The solid-liquid separation two-phase centrifuge can not only realize the separation of solid and liquid in the solid-liquid mixture. It can also quickly separate the liquid phase in a combination of two liquids of different masses. The whole feeding separation process is continuous, closed, and automatic.

2 Phase Decanter Centrifuge

The solid-liquid separation two-phase centrifuge can not only realize the separation of solid and liquid in the solid-liquid mixture. It can also quickly separate the liquid phase in a combination of two liquids of different masses. The whole feeding separation process is continuous, closed, and automatic.

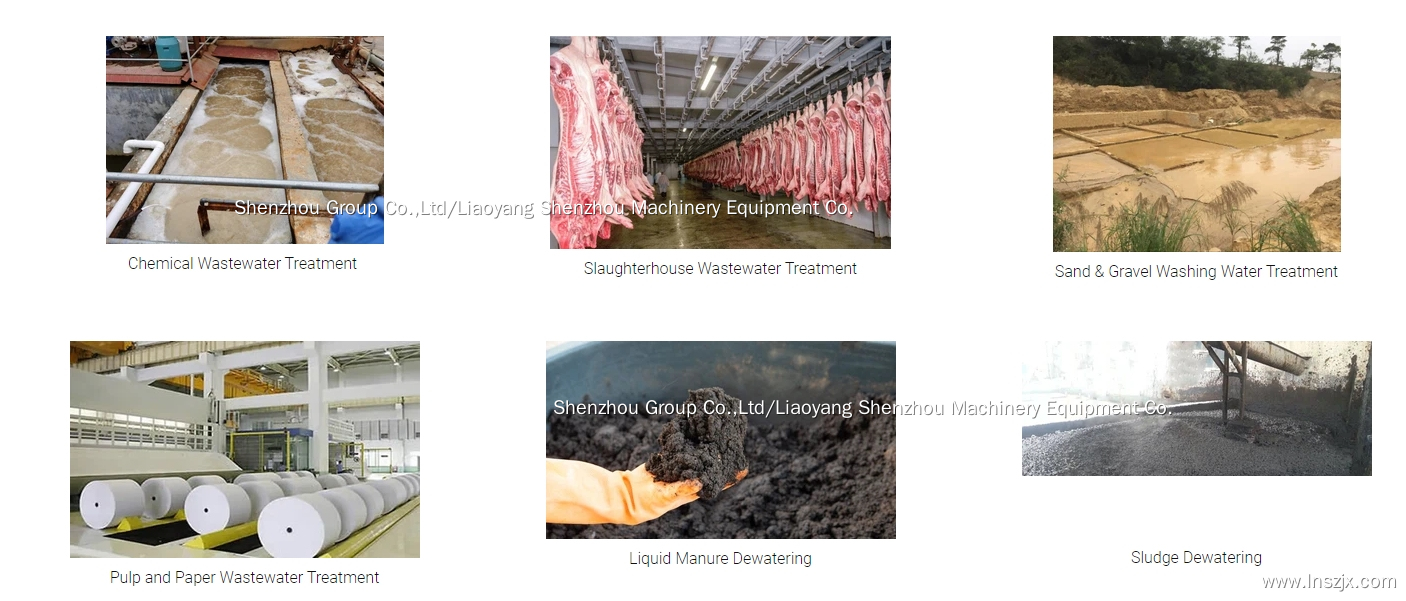

Applications For 2 Phase Decanter Centrifuge

Shenzhou two-phase centrifuge can realize the separation of two immiscible liquids and liquid and solid. The entire separation process is continuous and automatic without human operation. Two-phase centrifuges are widely used in many fields such as environmental protection, sewage treatment, chemical industry, steel, food, fermentation, medicine, metal, and non-metal mineral mining.

Shenzhou Decanter Centrifuge for Municipal Sewage Treatment Solutions

Product Description

The Shenzhou Urban Sewage Centrifuge stands out as the most cost-effective, eco-friendly, and efficient equipment for solid-liquid separation in treating urban domestic sewage and dehydrating sludge. With over 20 years of expertise in sludge dewatering and thickening, Shenzhou SEPARATION comprehends the specific demands and technological intricacies of sewage treatment plants and the water industry. Our urban sludge centrifuges exhibit exceptional adaptability to low-concentration treatment, eliminating the need for additional thickening while achieving efficient dehydration to meet integrated thickening and dewatering process requirements. The Shenzhou Separate Decanter Centrifuge boasts a distinctive structure, advanced control system, and standardized design, significantly reducing labor costs in later stages and contributing to cost savings for municipal sewage treatment plants.

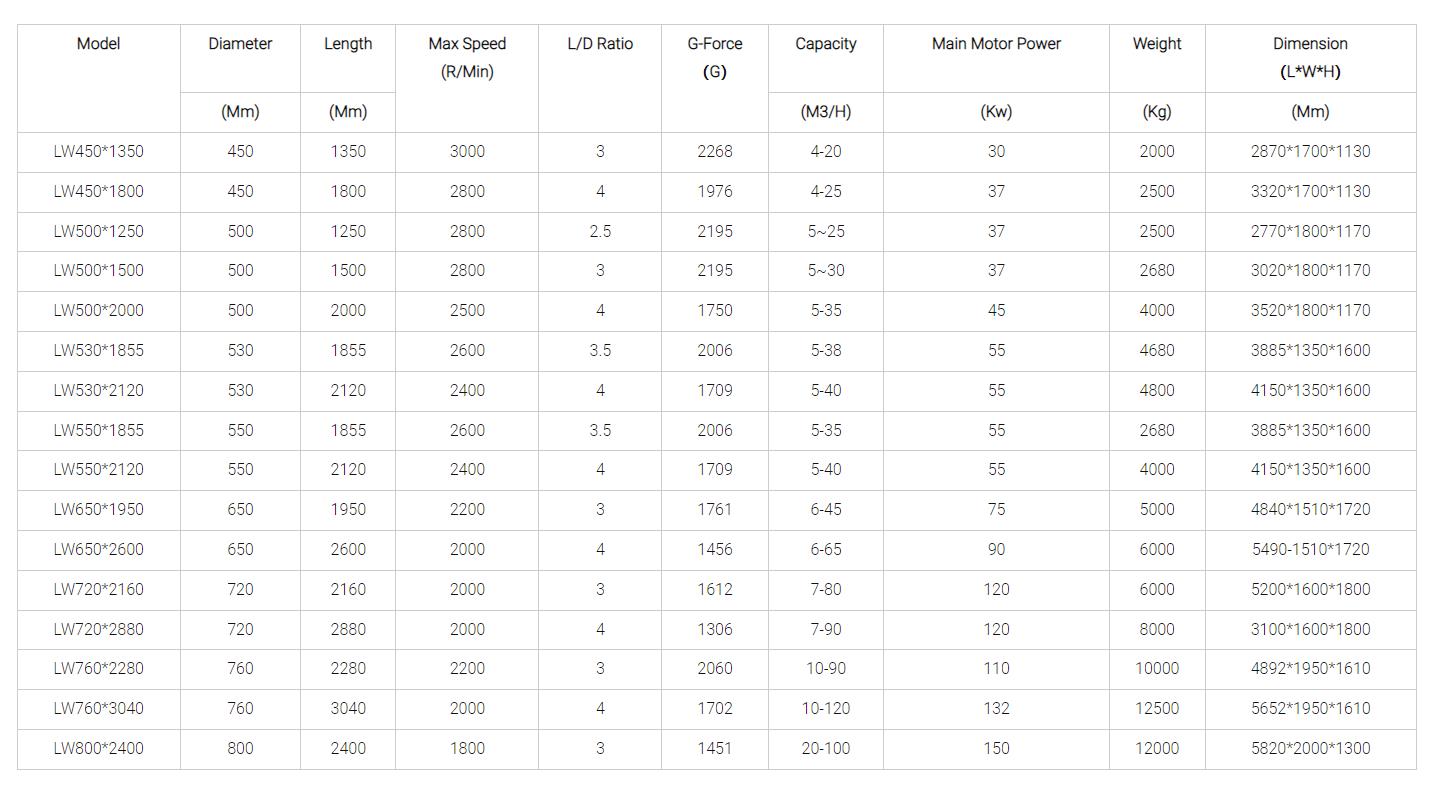

Muncipal Waste Water Centrifuge Parameters

Drive Type: VFD + PLC + HMI

Bowl Material: SUS2205(Duplex Stainless Steel) / SUS2304 (Duplex Stainless Steel) / 316L / 316 Centrifugal Casting

Screw Material: SUS2205(Duplex Stainless Steel) / SUS2304 (Duplex Stainless Steel) / 316L / 316 Centrifugal Casting

Bearing: SKF / NSK

Wastewater Treatment Process

Cut and crush the biochemical sludge.

Pump the sludge (concentration ≥0.5~4%) into the centrifuge.

Add (concentration 1~3‰) PAM solution into the feed pipe through the automatic dosing device to make the sludge form flocs into the centrifuge.

The dewatered sludge cake is discharged from the bowl.

The dewatering system is widely used in oxidation ditch, AB, A/O, A3/0, SBR, MBR, anaerobic fermentation and other processes as well as traditional wastewater treatment processes, and can treat urban domestic sewage, municipal sewage, garbage leachate, municipal tap water and some industrial wastewater.

More Similar Application

Characteristics Of Suspension Materials

The larger the solid particles in the material, the easier it is to separate. The size of the solid particles varies, and the final separation effect is determined by the small particle solid phase. This machine can generally remove solid particles above 5 um. When the solid particles are especially small, they will not settle and separate out, but will be discharged together with the clarified liquid; The final separation effect depends on the distribution of solid particles in the material. The more particles above 5 um, the better the separation effect; On the contrary, the separation effect is worse.

Generally, crystalline solids and fibrous solids are easier to separate, while flocs and paste solids are more difficult to separate. Due to the large maximum water solubility of flocs and paste solids, when spirally pushing sediment, it is easy to slip and affect the separation effect, so the flow rate should not be too large when separating flocs and paste solids.

The greater the weight difference between the solid phase and the liquid phase, the better the separation, and vice versa, the worse the separation effect The lower the liquid viscosity, the easier it is to separate. When the liquid viscosity is higher, the solids entrained in the clarified liquid increase, and the separation effect becomes worse. At this time, the material temperature can be increased and the viscosity can be reduced to improve the separation effect (the maximum feed temperature is not greater than 95 ℃).

Selection Of Feed Flow (I.E., Processing Capacity)

From a separation perspective, the smaller the feed flow rate, the smaller the axial flow rate of the material in the drum, the longer the residence time of the material in the drum, and the better the separation effect. As the feed volume increases, the axial flow rate increases, and the retention time of the material in the drum decreases. The separation effect becomes worse.

The feed volume of the centrifuge is also limited by the maximum slag removal capacity of the spiral. If the feed volume is too large, the separated sediment will not be discharged in a timely manner, resulting in blockage of the drum.

Therefore, when using the centrifuge, the appropriate feed flow rate should be selected based on the material characteristics, separation requirements, and the solid content of the material, Generally, when the solid content is large, the feed rate should not be too large. The appropriate feed rate can be determined after comparing the separation effects of various flows. Generally, it is recommended that the flow rate should not be too large for materials that are difficult to separate, and the flow rate for materials that are easy to separate can be larger. However, attention should be paid to the maximum slag discharge amount of the spiral, otherwise it will cause material blockage

Technical Service

- Technical direction when installation, debugging

- Training for operation and maintain worker

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Hot Tags: industrial large capacity centrifuge, China industrial large capacity centrifuge manufacturers, suppliers, factory, centrifuge rotor, 2 Phase Solid Bowl Decanter Centrifuge, clarified apple juice, filtration in wastewater treatment, Large industrial separation equipment, centrifuge for solid liquid separation

Products Packaging