Our 2 Phase Disc Centrifuge offers superior performance with customizable specs, allowing for precise customization to meet the unique needs of each customer. With high-speed rotation and advanced separation technology, this centrifuge efficiently separates solid particles from liquids, making it ideal for a wide range of industries. Its durable construction and easy maintenance ensure long-lasting performance and reliability, giving customers peace of mind and confidence in their investment.

At our company, we serve with a commitment to superior performance and customized specifications for our 2 Phase Disc Centrifuge. Our team of dedicated experts ensures that each centrifuge is meticulously designed and tested to meet the highest standards of efficiency and reliability. With a focus on precision engineering and innovative technologies, we provide our customers with a product that delivers exceptional results and maximizes operational efficiency. Whether you are in the pharmaceutical, food processing, or chemical industry, we are here to serve your unique needs and exceed your expectations. Choose us for unbeatable quality and service excellence.

At our company, we are dedicated to serving our customers with the highest quality products, including our 2 Phase Disc Centrifuge. With superior performance and customizable specs, this centrifuge is designed to meet the unique needs of each customer. Our team of experts is committed to providing excellent service and support throughout the entire purchasing process, ensuring that you receive the perfect solution for your specific requirements. We strive to deliver exceptional value through our innovative products and unparalleled customer service. Trust us to serve you with the best centrifuge technology on the market.

Product Description

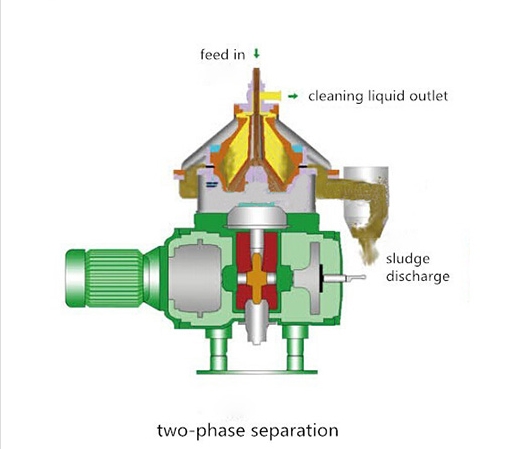

The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge.

The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge. The disc stack separator G force is up 12000g. Generally, the G force of the decanter centrifuge is about 3000G. The high speed and G force makes the disc stack separator to produce high clarified liquid. However, the materials separated by disc separator should not have high solid content or big particles. Usually the particles content should be less than 3%, it’s better to be 1%. Therefore, in some application, pre-treatment will be carried out by decanter centrifuge or other separation equipment, and then clarification and separation will be carried out in the 2 phase disc stack separator. The 2 phase disc stack separator is widely used in vegetable oil clarification, biological and chemical pharmaceutical industry, dairy and beverage industry, biofuel and marine oil clarification, etc.

2 Phase Disc Stack Separator Working Principle:

The material to be clarified enters the bowl through a feed pipe. In the distribution cabinet of the disc separator, the material is smoothly accelerated until it is synchronized with the speed of the rotary bowl. The disc stack in the rotating cylinder divides the material into many thin layers, forming a large area of clarification area. The high-speed centrifugal force makes the solid slag separated from the liquid in the disc stack deposit into the solid slag collection cavity at the edge of the bowl. The self-discharging 2 phase disc separator can be adjusted according to the material.

2 Phase Disc Stack Separator Parameter:

Technical Service

- Technical direction when installation, debugging

- Training for operation and maintain worker

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Hot Tags: industrial large capacity centrifuge, China industrial large capacity centrifuge manufacturers, suppliers, factory, centrifuge rotor, 2 Phase Solid Bowl Decanter Centrifuge, clarified apple juice, filtration in wastewater treatment, Large industrial separation equipment, centrifuge for solid liquid separation

customers from other countries visited Shenzhou Group

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Food and beverage centrifugee & separator and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the 2 phase disc Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 phase disc Centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In essence, a long-standing 2 phase disc Centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1