The 3 Phase decanter centrifuge is a highly efficient and customizable product that offers continuous operation, spiral discharge, and high capacity. Its compact structure and convenient maintenance make it ideal for various industries. With fully enclosed operation, clean on-site production, and low daily operation costs, this centrifuge offers a cost-effective solution for solid-liquid separation. Made with high-quality materials and equipped with safety overload protection devices, this centrifuge ensures safe and reliable operation for industrial and municipal wastewater treatment, oil and gas drilling mud control, and various other applications.

At our company, we are dedicated to serving our customers with the most efficient and customizable 3 Phase Decanter Centrifuge on the market. With a strong focus on quality and performance, we strive to provide a solution that meets the unique needs of each individual customer. Our team of experts is always on hand to offer support and guidance, ensuring a smooth and successful operation. From initial consultation to after-sales service, we are committed to serving you every step of the way. Trust us to deliver a reliable and high-performing product that will exceed your expectations.

At our company, we serve businesses looking for an efficient and customizable solution with our 3 Phase Decanter Centrifuge. Our product is designed to meet the diverse needs of our customers, offering high-performance separation of solids, liquids, and oils. With a focus on durability and reliability, our decanter centrifuge is built to last and provide consistent results. Additionally, we provide customization options to tailor the machine to specific requirements, ensuring maximum efficiency and productivity for your operations. Trust us to serve you with top-quality equipment that delivers exceptional performance and value.

Product Description

LWSthree-phase centrifuge can continuously feed, separate and discharge at full speed. It has the characteristics of compact structure, easy sealing, stable operation, low noise, large processing capacity, low energy consumption, high degree of automation, low labor intensity, convenient operation and maintenance, wide application range and so on. For some materials that are difficult to separate, in addition to taking corresponding adjustment measures for the separat-ed materials themselves, the centrifuge can also be adjusted and improved accordingly:

1. Increase the length diameter ratio;

2. Adjust the rotating speed of the drum;

3. Adjust the differential speed between the drum and the discharge screw;

4. Change the half cone angle of the drum cone section and adopt multi cone angle sorew;

5. Adjust the overflow radius of the liquid phase outlet;

6. Change the number of screw heads and screw lifting angle of discharge screw;

7. Add BD plate structure;

Combined Driving Mode

Single Motor Drive: Single motor drive generally adopts a frequency conversion motor + frequency converter to drive the drum and screw at the same time.

The method is simple, the operation is simple, and the manufacturing cost is low. Single motor drive is mainly used for materials with constant solid content, and there is no strict requirement for the water content of the discharged solid phase. Because there is no necessary differential adjustment mechanism, the differential between the drum and the screw can only be realized by changing the gear transmission ratio or changing the drum speed.

Dual Motor Drive: Dual motor drive generally adopts two frequency conversion motors + two frequency converters tocontrol the dynamic rotation of drum and screw respectively.

ln the dual motor drive mode, the differential speed between the drum and the screw is adjusted by simply adjusting the speed of the motor. This driving mode is applied to materials with variable solid content and strict requirements for discharged solid water content.

Hydraulic Drive: The hydraulic drive generally adopts frequency conversion motor + frequency converter + hydraulic motor to drive the drum and screw respectively.

ln the hydraulic drive mode, the differential speed between the drum and the screw can be adjusted by the hydraulic motor. When moving at very low differential speed, its degree and stability are better than other driving methods.When the drum rotates normally, both the drum and the screw operate at a certain constant speed. Once the load of the screw pusher increases, the hydraulic motor will adjust the screw pusher to accelerate the operation to prevent material blockage.When the machine is stopped for cleaning due to material blockage, the hydraulic system can drive the screw pusher independently to improve the cleaning and maintenance efficiency.

Structure And Working Principle

In the three-phase horizontal screw centrifuge, the materials to be separated enter the acceleration chamber of the screw pusher through the feed pipe and then enter the inner wall of the rotating drum at high speed. Due to the different specific gravity of light liquid phase heavy liquid phase insoluble solid phase in the materials, the centrifugal force on the three-phase materials is different, and the insoluble solid phase is settled to the inner wall (outermost) due to the largest centrifuge with the largest specific gravity, Due to the minimum centrifugal force, the light liquid phase is settled farthest (outermost) from the inner wall of the drum. The heavy liquid phase is in the middle. The insoluble solid phase is discharged from the solid phase outlet through the screw pusher with relative differential speed with the drum. The light and heavy liquid phases are separated by different structures in the machine. The heavy liquid phase is discharged through the centripetal pump and the light liquid phase is discharged by gravity, so as to achieve the purpose of three-phase separation of materials. The light and heavy liquid phases of our three-phase horizontal screw centrifuges are discharged by gravity and centrifugal force respectively, so as to effectively avoid the incomplete separation of materials caused by the mixing of materials. When working, the ordinary three-phase horizontal screw centrifuges often cause incomplete separation due to the unstable components of light and heavy liquid phases, Our three-phase horizontal screw centrifuge can adjust the interface of light and heavy liquid phases according to the changes of material components, so as to achieve the ideal separation effect.

Advantage

At present, three-phase horizontal screw centrifuges are widely used in chemical industry, light industry, medicine, food, papermaking, mining and other industries. And coal tar industry; Petrochemical industry; Fishing powder industry, swill oil industry, electrolytic copper industry, and the separation of oil, water and slag from waste residues in slaughterhouses.

Material concentration: the material is required to have good fluidity, subject to not affecting the feed. The weight percentage of mixed liquid and solid concentration is generally ≤ 20% (good fluidity, which can be relaxed appropriately).

Material temperature: the allowable material temperature of this centrifuge is ≤ 900C.

Separation Range

A. When the liquid viscosity is small and the solid particle size is large, the specific gravity difference between solid, liquid and liquid is required to be ≥ 0.05g/cm3 (solid weight and liquid light).

B. When the liquid viscosity is small and the specific gravity difference between solid and liquid is large (specific gravity difference ≥ 1g / cm3), the solid particle is required to be ≥ 0.005mm and the specific gravity difference between liquid and liquid is required to be ≥ 0.05g/cm3.

C. When the liquid viscosity is large or the specific gravity of solid-liquid is small and the solid particles are very fine, the separation effect will be affected or even not applicable.

D. When the solid particles are easy to be damaged, the separation effect will also be affected.

Other

Industrial and municipal wastewater treatment, oil and gas drilling mud / drilling fluid control, washing, separation and dehydration of starch, separation of mycelium and fermentation broth of antibiotics, dehydration of soybean and wheat protein, dehydration of fish meal and meat, dehydration of distiller's grains, clarification and extraction of fruit juice, separation and purification of animal and vegetable oil, production and purification of olive oil, palm oil and avocado oil, separation and purification of coal tar, classification of kaolin and graphite Classification and dehydration of dyes and pigments, flotation of fine coal and slime dewatering, mineral classification and dewatering principle.

Equipment Characteristics

The centrifuge can clarify, separate and dehydrate 0.002-3mm materials or classify 1um-5um solid particles. It has the characteristics of wide application range, continuous work, large processing capacity, low cost and convenient maintenance. It is the best equipment for solid-liquid separation.

The differential has high precision, compact structure, stable operation and high safety.

The main bearing adopts imported bearing to ensure its operation accuracy and convenient operation.

The contact parts with materials are made of high-quality stainless steel.

The whole machine is equipped with a variety of safety overload protection devices to ensure safe production.

The whole machine system is designed with ordinary type and explosion-proof type to meet different requirements.

Drum cone structure with large aspect ratio, high speed and multiple angles.

The screw pusher adopts hard alloy material for hard surface treatment, with strong wear resistance.

The rack can be designed into low center of gravity, high support and mobile according to the needs of users.

With BD plate spiral structure, it is suitable for the concentration and dehydration of activated sludge and materials that are difficult to separate.

According to the actual requirements, it can be equipped with double frequency conversion and intelligent full-automatic control system.

Main Features

■ Continuous operation, spiral discharge, high capacity.

■ Compact structure and convenient maintenance.

■ Fully enclosed operation, clean and pollution-free on site.

■ The amount of flocculant and cleaning water is small, and the daily operation cost is low.

■ Compact equipment layout and small floor area can significantly reduce land acquisition and infrastructure investment.

Material Selection

According to the user's requirements, the product contact can be made of austenitic stainless steel (321, 316L...), Haines alloy, titanium alloy or other anti-corrosion materials.

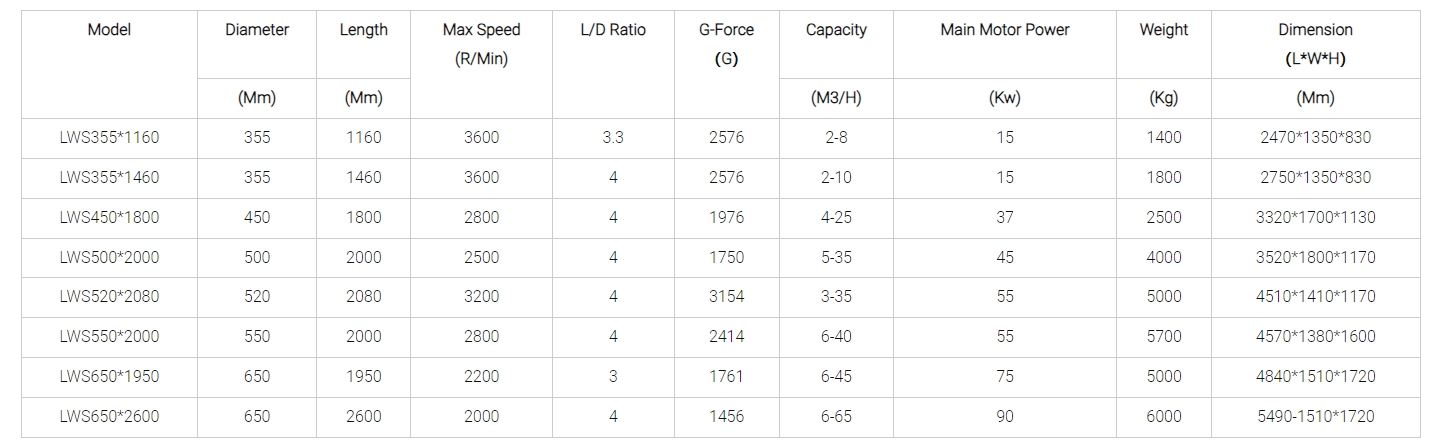

Technical Parameter

Other Main Components And Parts

Products Packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient shipping packaging services will be provided.

Customer Photos

Our Services

Pre-Service

1. 24 hours onlinne consult and service

2. Introduce the product to the customer in detail, answer the question raised by customer carefully;

3. Make different plans for choice according to the needs and requirements of customers;

Sale Service

1. Ensure product with high quality before delivery;

2. Packing and shiping carefully;

3. Delivery on time;

4. Provide full set of documents as customer’s requirements.

After-Sale Service

1. Help to install and debug the equipment;

2. Provide 24 hours techincal support by e-mail or phone;

3. Keep sufficient replaceable spare parts;

4. Help customers slove any other questions about products or other aspect;

5. Establish long-term and friendly relationship.

Hot Tags: tricanter centrifuge, China tricanter centrifuge manufacturers, suppliers, factory, underground mining dewatering, sludge dewatering and drying, Olive oil extraction centrifuge, Oil extraction Centrifuge, The purpose of centrifuges, liquid liquid centrifugal separator

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1