LWS355 3 Phase Decanter Centrifuge For Oil Filter- Shenzhou Machinery

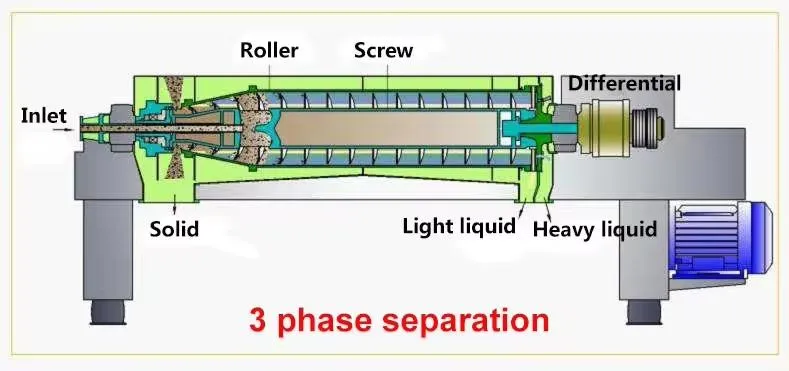

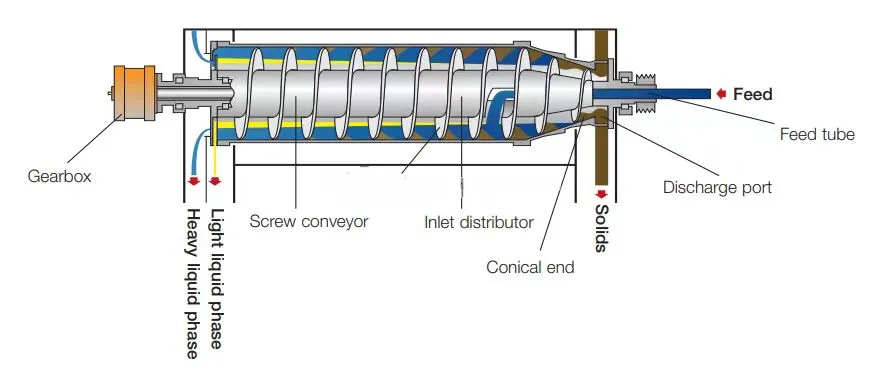

LWS series three phase decant centrifuge is used for solid-liquid-liquid separation, namely one kind of solid phase (with largest specific gravity ) and two kind of immiscible liquid phase with different density. The conveyor rotates in the same direction as the bowl, but at a different speed, the material is fed into the bowl through a stationary feed pipe. Centrifugal forces cause instant sedimentation of the solids on the wall of the bowl, while two liquid phases forming light liquid phase layer and heavy liquid phase layer. Scroll conveys the solids towards the conical end of the bow, and out of centrifuge from solid discharge port. The light liquid phase then is discharged out continuously through the overflow port at the large end of the bowl, and the heavy liquid phase will be discharged out through the centrifugal pump large end of the bowl, thus realizing the three-phase separation.

LWS series three phase decanter centrifuge is widely used in oil separation

3-Phase Decanter Centrifuge Application Scope:

1) City tap water, domestic sludge dewatering;

2) Oil drilling mud dewatering;

3) Sludge Oil Recovery;

4) Refinery sludge concentrated dehydration;

5) Distiller's grains dehydration;

6) Paper, printing and dyeing wastewater separation;

7) Medical sludge dewatering;

8) Soy protein dehydration;

9) Plant oil clarification and separation;

10) Cosmetic clarification and separation;

11) Bleaching powder separation.

12) Palm oil sludge Separating.

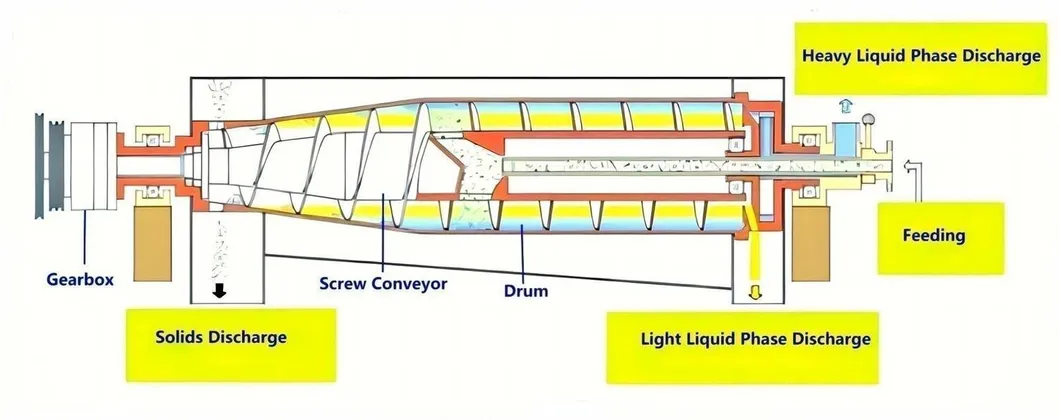

Structure Diagram of 3-phase Decanter Centrifuge

Working Principle:

The three-phase decanter centrifuge is formed by adding the heavy liquid pressure discharge mechanism on the basis of the two-phase horizontal screw machine structure. The material is continuously introduced into the spiral inner cylinder through the feed pipe, and enters the rotating drum after acceleration, using the liquid-solid-solid specific gravity difference. Under the action of the centrifugal force field, heavier solid phase deposits on the drum wall to form a sediment layer. The spiral continuously pushes the deposited solid phase to the cone end of the drum and discharges it out of the machine through the slag discharge port. The two liquid phase materials are divided into light and heavy two phases to form a light liquid phase and a heavy liquid phase respectively. The light liquid phase is discharged by gravity through the large end overflow of the drum, and the heavy liquid phase is discharged by pressure through the impeller mechanism. So as to realize the separation of liquid-liquid-solid three-phase mixture with different densities

Three Phase Centrifuge Specification

Model | Diameter | Length | Max Speed (R/Min) | L/D Ratio | G-Force (G) | Capacity | Main Motor Power | Weight | Dimension (L*W*H) |

(Mm) | (Mm) | (M3/H) | (Kw) | (Kg) | (Mm) | ||||

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2500 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS520*2080 | 520 | 2080 | 3200 | 4 | 3154 | 3-35 | 55 | 5000 | 4510*1410*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

If you want to know more please contact me:Cathy Tel:+8613130722088(WhatsApp)

Website: www.lnszjx.com