Professional LWS520 Industrial Fish Oil Decanter Centrifuge manufacturers

In the rendering method of oil extraction, adding a SHENZHOU decanter centrifuge can increase the oil extraction rate by up to 3%, while also reducing fat in dry matter (FiDM) by at least 2%—with even greater fat reduction observed in the final fish meal.

This not only increases the revenue from the oil fraction, but also raises the market value of the protein due to the lower fat content. As an added benefit, the extracted oil is so clear that further processing in a high-speed separator can be kept to a minimum.

Product Introduction

The technological procedure of Three-phase Solid-bowl Centrifuge:

The fish water after fish rolling flows into the temporary storage tank, charged by pump or high level tank, before which the fish water shall be heated to 85-90 degrees by steam heater or electric heater, and then enters to the three-phase solid-bowel scroll centrifuge to be separated; The fish scraps, fish oil and waste water are separated for one time. Fish oil is canned through steam or other heating approaches, and the waste water is sent to the dryer for evaporation through pumps, while the fish scraps are also sent to the dryer, processing into fishmeal by the conveyer.

Configuration

1.Motor: Dual motor and Dual inverter.

2.Bearing is S-K-F.

3.The PLC touch screen .(Siemens)

4. Run mode: 24 hours continuously.

7. Starting and driving way: inverter

8. Vibration sensors: when the machine have problem. The instrument will automatically alarm and make the machine stop.

9. Quick sensors is can show the running speed.

10. Feeding method: continue feeding.

11. Discharging way: automatic continue discharge.

Material:

1. All the part contacting with the material is ss304.the machine bowl is SS304.

2. Engine base: carbon steel

3. Base on the surface: protective primer and finish for carbon steel.

4. The spiral is used to surfacing hard alloy wear-resistant layer.

5. The bowl exit is cermet.

Professional LWS520 Industrial Fish Oil Decanter Centrifuge manufacturers

| Product Name | 3-Phase Horizontal Decanter Separation Centrifuge Equipment |

| Material | SS304/Duplex |

| Drum Diameter | 520mm |

| Main Motor | 55KW/380V/50HZ |

| Auxiliary Motor | **** |

| Maximum Speed | 3500 r/min |

| Maximum Separator Factor | 3154g |

| Capacity | 5 m3/h |

| Weight | 5000 kgs |

| Product Dimension | 4150x1410x1170mm |

| HS Code | 8421192000 |

Company Advantages

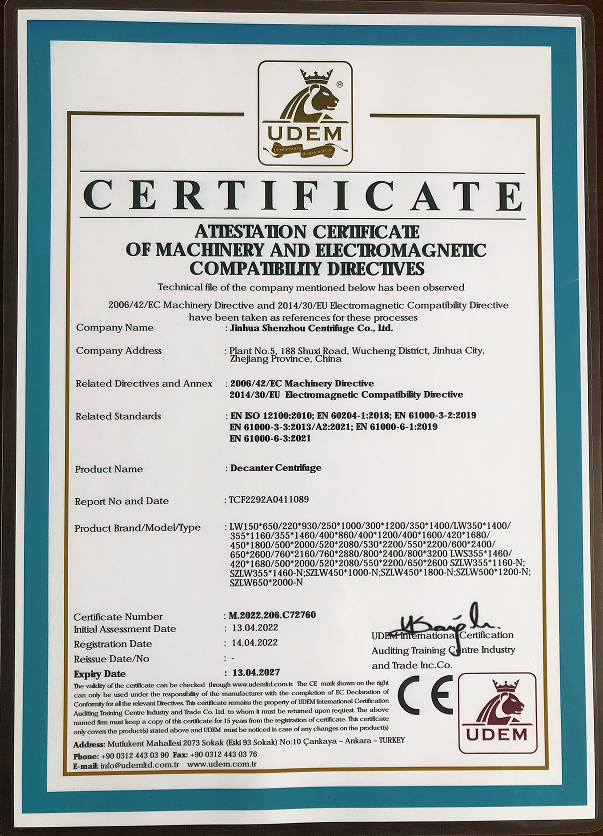

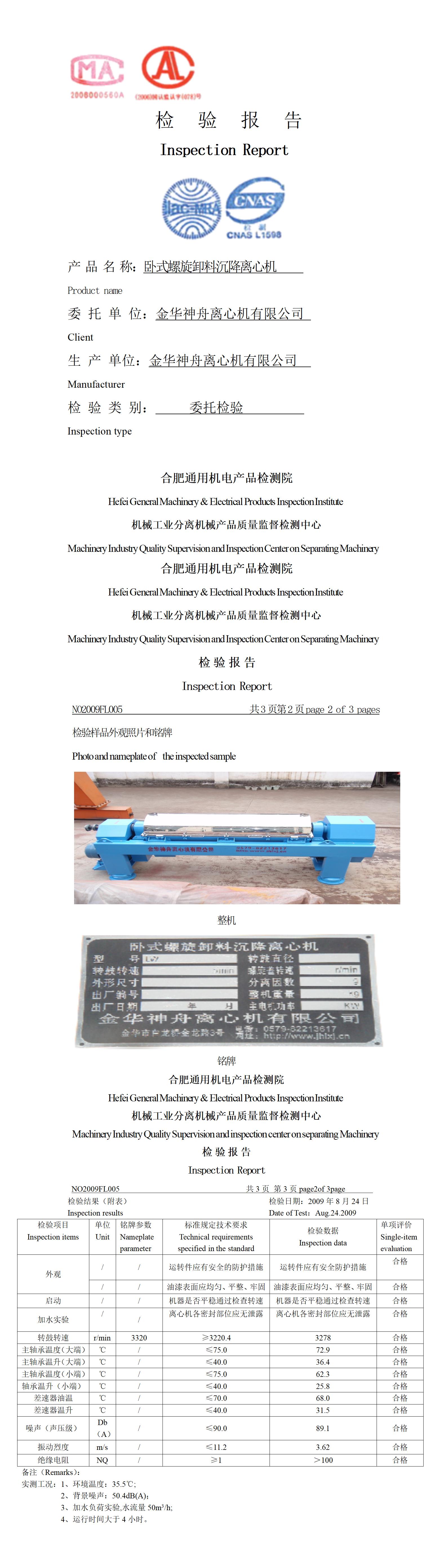

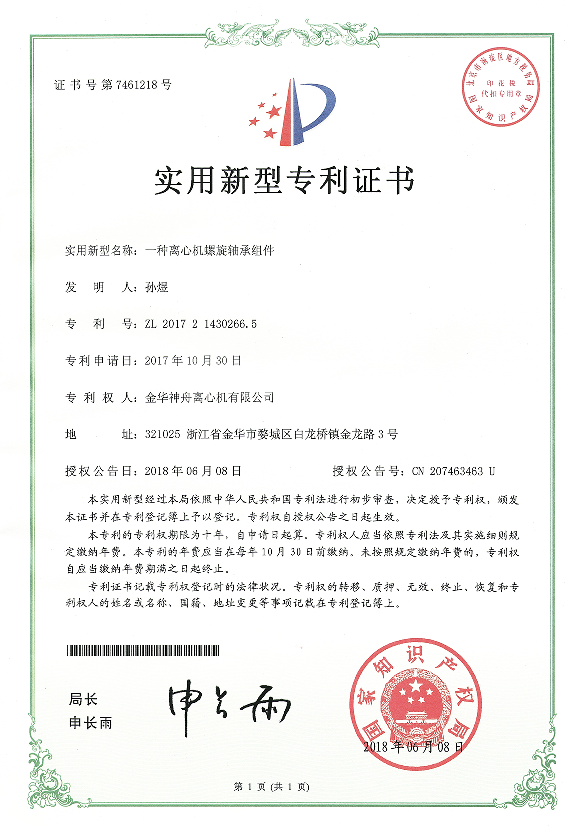

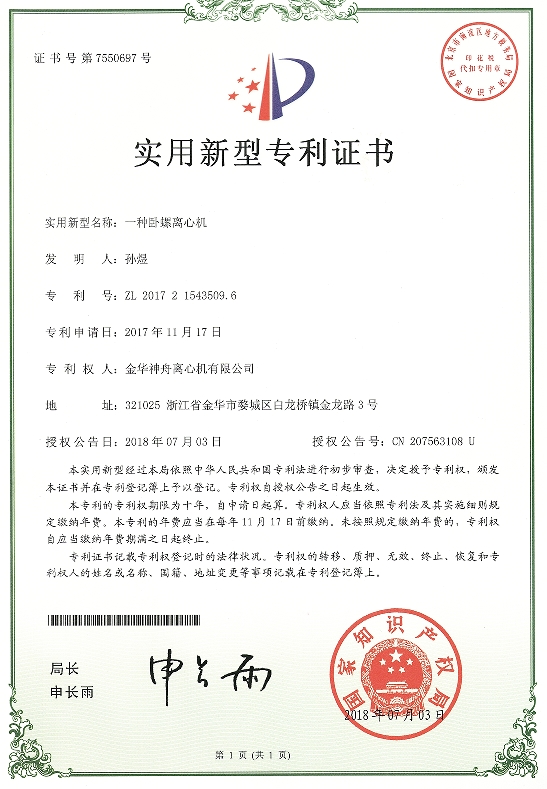

Certifications and Patents