Kitchen waste leachate oil-water residue separation integrated machine - horizontal spiral discharge settling centrifuge (three-phase horizontal spiral centrifuge)

The 3 phase decanter centrifuge is a powerful oil-water sludge separator designed to handle various types of organic waste, including kitchen waste, fruit and vegetable waste, and agricultural waste. Utilizing patented multi-stage crushing technology, this centrifuge achieves 100% crushing and utilization of organic matter, enhancing economic benefits and improving overall process efficiency. With a safe and environmentally friendly treatment process, this centrifuge offers a sustainable solution for oil-water separation without any pollution discharge, making it a cost-effective and energy-efficient option for waste management.

Our company specializes in providing cutting-edge separation solutions for various industries, particularly for the oil and gas sector. With a strong focus on innovation and efficiency, we have developed the 3 Phase Decanter Centrifuge - Oil-Water Sludge Separator. This high-performance equipment offers unmatched precision in separating oil, water, and sludge, ensuring optimal results and cost-effectiveness for our clients. Backed by years of experience and expertise, we are committed to delivering top-quality products that meet the highest standards of performance and reliability. Trust us to be your partner in achieving seamless and efficient separation processes.

With a commitment to innovation and efficiency, our company specializes in producing high-quality 3 Phase Decanter Centrifuges for oil-water sludge separation. With a focus on precision engineering and advanced technology, we deliver reliable and cost-effective solutions for our customers in the oil and gas industry. Our team of experts is dedicated to providing exceptional customer service and support, ensuring seamless integration and operation of our products. Trust in our experience and expertise to help streamline your processes and maximize productivity. Choose our 3 Phase Decanter Centrifuge for superior performance and unmatched reliability.

Kitchen waste leachate oil-water residue separation integrated machine - horizontal spiral discharge settling centrifuge (three-phase horizontal spiral centrifuge)

In the oily wastewater from kitchen waste (hereinafter referred to as "catering wastewater"), the composition and form of oil are complex, generally existing in the main forms of suspended oil, dispersed oil, emulsified oil, dissolved oil, and oily solids. Among them, the difficult to treat is high concentration emulsified oil. At present, oil removal technologies can be classified into four categories: physical separation (such as gravity separation technology, filtration separation technology, coarsening separation technology, membrane separation technology, etc.), chemical separation (such as flocculation precipitation separation technology, electrolysis separation technology, acidification separation technology, etc.), physical and chemical separation (such as flotation separation technology, adsorption separation technology, magnetic adsorption separation technology, etc.), and biochemical separation (such as activated sludge separation technology, biofilm separation technology, etc.).

Centrifugal separation technology utilizes the density difference between two phases to generate different centrifugal forces through high-speed rotation, allowing light component oil and heavy component water to be distributed on the wall and center of the rotator, ultimately achieving a more thorough oil-water separation. The required dwell time for this technology is relatively short, and it does not require excessive equipment volume; The commonly used working equipment for centrifugal separation technology is a horizontal spiral discharge settling centrifuge.

Technical features:

1. It has a wide range of applications and strong compatibility, and can handle various types of organic waste, including kitchen waste, kitchen waste, market fruit and vegetable waste, agricultural and forestry waste, etc.

2. Patented multi-stage crushing technology achieves 100% crushing and utilization of organic matter, avoids organic waste, improves organic matter utilization rate, and enhances economic benefits.

3. Patented flexible limit crushing technology realizes the chemical separation of inorganic substances, avoids the mixing of inorganic substances into organic matter slurry, avoids the influence of inorganic substances on subsequent process treatment effects, and protects the normal operation of subsequent treatment equipment.

4. The treatment process is safe and environmentally friendly, with no pollution discharge such as wastewater and exhaust gas. The wastewater can be recycled after treatment, which is economical and energy-saving.

Our company's pre-treatment system consists of a stainless steel storage feeding system, a dual axis shredder, a screw conveyor, a pipeline magnetic separator, a kitchen pulp making machine, a belt conveyor, a storage tank, a conveying pump, pipelines, and various detection instruments;

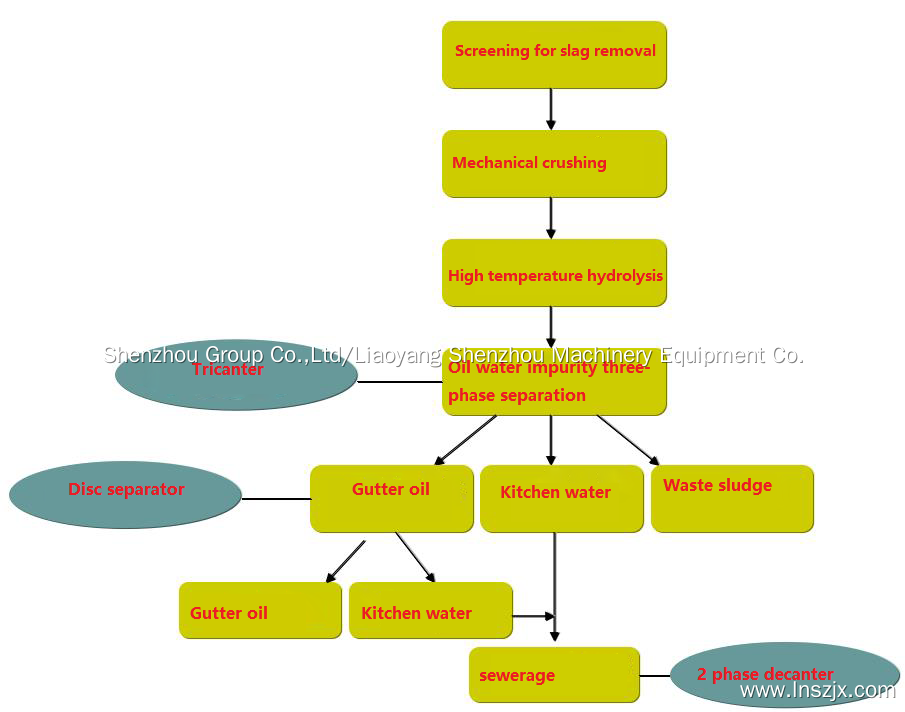

The collected milled water is poured into the stainless steel storage feeding system (equipped with axial screw conveyor), and the solid is transported by the axial screw conveyor of the stainless steel storage feeding system to the top slag discharge port for discharge, and enters the double axis shredder for crushing. The liquid (including small slurry particles) in the milled water passes through the screen of the stainless steel storage feeding system and enters the water storage tank. The stainless steel storage feeding system (equipped with axial screw conveyor) comes with a self-cleaning device, which can effectively prevent the blockage of the screen. At the same time, the stainless steel storage box is equipped with a grille to prevent some large items (plastic barrels, glass bottles, etc.) from mixing into the axial screw conveyor system.

The solid discharged by the stainless steel storage feeding system's shaftless screw conveyor enters the double axis shredder for crushing. After crushing, the milled water solid is transported by the screw conveyor to the slag discharge port at the top and enters the pipeline magnetic separator. After magnetic separation, the solid enters the kitchen pulp making machine for crushing and pulping. The screw conveyor is equipped with a liquid collection bin and a screen back cleaning device, and some liquid enters the water storage tank of the storage feeding system through the screen of the shaftless screw conveyor.

During the pulping process, the kitchen pulping machine adds hot water above 80 ℃ for cleaning the screening mesh of the kitchen pulping machine. The light substances such as plastics crushed by the kitchen pulping machine are discharged from the slag discharge port of the kitchen pulping machine and sent to the inorganic material collection box through a belt conveyor; The generated slurry is discharged from the slurry port of the kitchen pulping machine and enters the spiral extruder with a filtering device to remove long and large particle solids. After removing large particle impurities, the slurry is discharged from the extruder and enters the slurry storage tank.

The liquid collection bin of the stainless steel storage feeding system, the liquid collection bin of the shaftless screw conveyor, and the slurry generated by the extruder enter the storage tank. The slurry, which removes a large amount of sand and gravel, is transported to the heating tank. The heating tank is equipped with steam heating and stirring functions. After being heated to above 80 ℃ and insulated for 30 minutes, the slurry in the heating tank is then transported by a screw pump to a three-phase centrifuge for three-phase separation of oil, water, and slag.

More details,you can contact Shenzhou Group .

The buyers of 3 phase decanter centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 3 phase decanter centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 3 phase decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Regarding the attributes and functionality of the 3 phase decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1