Custom 2 phase Centrifuge manufacturers | Shenzhou

Over the years, Shenzhou has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. 2 phase Centrifuge We have professional employees who have years of experience in the industry. It is them that provides high-quality services for customers all over the world. If you have any questions about our new product 2 phase Centrifuge or want to know more about our company, feel free to contact us. Our professionals would love to help you at any time.Special requirements for 2 phase Centrifuge can be satisfied by us.

Product Details

Description

Shenzhou is a leading manufacturer of high-quality disc centrifuge separators designed for starch separation applications. Their disc centrifuge separators are specifically engineered to effectively separate starch from other components, ensuring high-quality and pure starch output. With precision engineering and advanced technology, Shenzhou's disc centrifuge separators offer efficient and reliable performance in starch processing operations. These separators are capable of handling large volumes of starch with minimal energy consumption, making them cost-effective and environmentally friendly solutions for starch separation. The robust construction and innovative design of Shenzhou's disc centrifuge separators guarantee long-term durability and consistent operation, meeting the demands of starch production facilities. By choosing Shenzhou as their supplier, manufacturers can benefit from top-of-the-line equipment that delivers superior starch separation results, ultimately enhancing productivity and product quality in the starch processing industry.

Application

DPF series Disc separator is mainly applied for purifying starch, previous concentrating, separating protein, and recovering starch production line.

Working Principle

Working Principle

The materials are transmitted to the heart parts of this machine, the inside of the drum. Under the action of strong centrifugal force, the materials (mixed liquid) pass through the intervals of a group of disk pieces bundles, and then, regarding the neutral hole of the disk pieces as the interface, the liquid with higher density (heavy phase) moves outward the neutral hole along the disk pieces, among which, the heavy residues accumulate in the sediment area, and the heavy phase flows to the large centripetal pump. The liquid with lower density (light phase) moves inward and upward along the disk pieces wall and gathers in the small centripetal pump. The heavy phase and light phase output by the large centripetal pump and small centripetal pump respectively.

Features of product

Features of product

1. Big drum diameter and large area of disc ensure the excellent effect of separation and concentration.

2. Top-suspension driving can be applied, which stabilizes the separator rotation and extremely improves the life span of bearings and main shaft.

3. Automatic control on lubricating system is applied, which assures and prolongs lifetime of driving system.

4. Big nozzle is applied, which increases the feeding capability, reduces the chances of block and assures the continuous production.

5. Lifting drum is fitted with the hydraulic system, which is convenient for drum inspection and nozzle replacement.

6. The material of drum adopts special high-strength corrosion-proof stainless steel which assures the safety and stability of separator.

7. This machine can treat the materials with various concentrations without internal adjustment.

8. It is equipped with inner circulation system which keeps separation stability and improves adjustment as well as control accuracy.

Starch separator structurfeatures

Starch separator structurfeatures

1 . Auto-safe lubracation system

2 . Firm metal defense cover

3 . Special suspension-branch make sure the drum work stably in high rotation speed

4 . The auto-control bearing lubracation system make sure a long-time and reliable work of the drive system

5 . The critically manufactured stainless steel shell is hard and durable,and never fading

6 . Firm vertical shaft, which installed hydraulic ascending and descending system inside, compact structure and convenient operation

7 . The designed advanced inner-cycling system make sure it regulate separation effect exactly, and have a stable realible separation

8 . Ciritically processed pedestal pedestal make the machine stable, it has a very canonical machinary dimension

9 . Motor frame with vibration-absorption equipment

Product General

The starch separator are mainly used in pre-concentration starch, separation of starch and gluten, concentration of gluten(protein), clarify of process water in the after step and so on.

Graining process : Corn / Cassava/ wheat/ potato starch

People will crash and separate the mature crops depend on their physical properties, then obtain starch. So the starch separator is the key in the process of starch extraction.

In the starch separation process, the separator rotates in high speed then creates the centrifugal force, so the separation efficiency is improved. At the same time maximize the production efficiency.

We devote ourselves to make starch separator to the most professional and efficient in starch processing industry, it collects all the advantages of various separator such as small vibration, large capacity, stable running and so on.

It’s mainly used in pre-concentration starch, separation of starch and gluten, concentration of gluten (protein) , clarify of process water in the after step and so on.

Product competitive advantage:

Product competitive advantage:

1 , Big diameter of drum, large area of disk, strong capability of production(separation), excellent effect of separation.

2 , Adopting top-suspension driving, which makes the separator with high rotation stability, largely improves the using life of bearings and main shaft.

3 , Adopting automatic control of lubricating oil circuit, which protects and prolongs the using life of driving system.

4 , Adopting big nozzles , which has big feed capacity, reduces the chances of block, assuring the continuous production.

5 , Fitted with hydraulic system for lifting drum, which makes more easily to check the drum and replace nozzles.

6 , Operating easily, the workers can master the operation regulation in short.

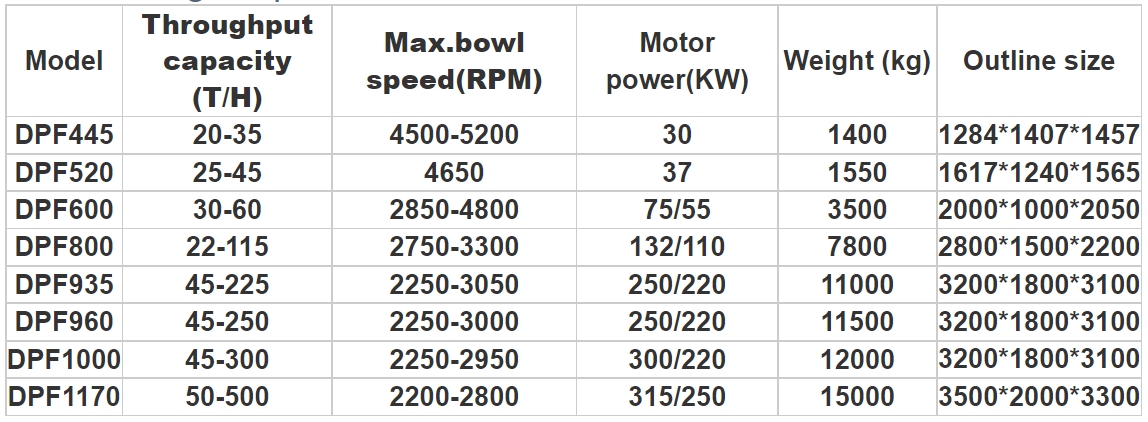

Product Parameters:

You might also be interested in other industry solutions:

Corn Starch/ Wheat Starch/ Wheat Gluten Potato Starch Sweet Potato Starch Cassava Starch Pea Starch And Protein

Solution Tailored to Your Needs

General layout plan

With a land prepared, the next thing you should consider is planning the general layout, which is a crucial foundation of a sustainable and cost-effective manufacturing.

Turn to us for help and we will present you the design for your plant by considering water, steam, electricity supply and etc.

Process design

Combining our engineering expertise, industry know-how and practical skills with your knowledge, we provide the optimized and customized process design for your plant.

3D plant design

On the basis of plant layout design, combined with real situation, we can design a three-dimensional model of the entire plant. All the equipment, piping and instruments, any detail can be shown in the model, not only allowing you to have an intuitive understanding of the plant, but also providing overall information support for plant construction, equipment installation and future expansion.

Automatic control system

We offer economical and most effective process automation solutions for the entire production line. Our RES automatic control system is developed based on PLC/DCS system.

Data integration

From the perspective of the overall operation of the factory, Myande intelligent data integration management system collects basic data from raw grain procurement, warehousing, processing, inventory, sales and logistics, relying on the interconnection network system of each workshop. It provides real-time, accurate and traceable data reports for the current storage, processing and shipping.

Equipment manufacturing

We owns in-house manufacture base of more than 120,000 SQM integrating R&D, production, project management which represents advanced engineering capability in the industry.

Installation and commissioning

After finishing the installation of all machines, we offer on-site commissioning service to ensure compatible functioning.

Every move of the machine needs strong technical support from our experienced engineers. The only principle is that you can start manufacturing right after the commissioning.

Rice Starch And Protein Modified Starch Glucose Syrup/ Maltose Dextrose Monohydrate Dextrose Anhydrous

Fructose Syrup Maltodextrin Lysine Bioethanol Sorbitol

Citric Acid DDGS