High-speed 2 Phase Centrifuge with 12000g G force

Product advantages

With a maximum speed of 12000g force, our high-speed 2 phase centrifuge ensures efficient separation of samples in a timely manner. The advanced technology and precise engineering of this centrifuge guarantee reliable and accurate results every time. Its compact design and user-friendly interface make it a convenient and essential tool for laboratories and research facilities.

Company profile

Our company specializes in high-quality laboratory equipment, such as the High-speed 2 Phase Centrifuge with 12000g G force. With a focus on innovation and efficiency, we provide top-of-the-line centrifuges that offer fast and reliable results for your research needs. Our team of experts is dedicated to delivering products that meet the highest standards of quality and performance. Count on us for cutting-edge technology and exceptional customer service. Choose our centrifuge for your laboratory and experience the difference our company can make in advancing your scientific endeavors.

Enterprise core strength

With a commitment to innovation and cutting-edge technology, our company specializes in providing high-speed 2 phase centrifuges with a powerful 12000g G force. Our products are designed for efficiency and reliability, ensuring optimal performance in various applications including laboratory research and industrial processes. We prioritize quality and precision in every aspect of our manufacturing process, from design to production to testing. With a focus on customer satisfaction and continuous improvement, we strive to deliver top-of-the-line centrifuge solutions that meet the needs of our clients. Trust us for high-speed and high-quality centrifuge technology that pushes the boundaries of what is possible.

Product Description

The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge.

The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge. The disc stack separator G force is up 12000g. Generally, the G force of the decanter centrifuge is about 3000G. The high speed and G force makes the disc stack separator to produce high clarified liquid. However, the materials separated by disc separator should not have high solid content or big particles. Usually the particles content should be less than 3%, it’s better to be 1%. Therefore, in some application, pre-treatment will be carried out by decanter centrifuge or other separation equipment, and then clarification and separation will be carried out in the 2 phase disc stack separator. The 2 phase disc stack separator is widely used in vegetable oil clarification, biological and chemical pharmaceutical industry, dairy and beverage industry, biofuel and marine oil clarification, etc.

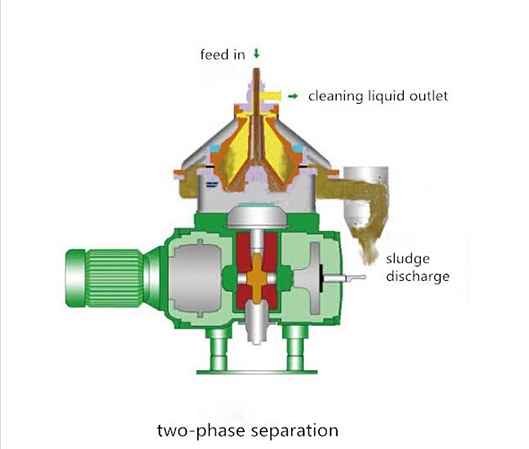

2 Phase Disc Stack Separator Working Principle:

The material to be clarified enters the bowl through a feed pipe. In the distribution cabinet of the disc separator, the material is smoothly accelerated until it is synchronized with the speed of the rotary bowl. The disc stack in the rotating cylinder divides the material into many thin layers, forming a large area of clarification area. The high-speed centrifugal force makes the solid slag separated from the liquid in the disc stack deposit into the solid slag collection cavity at the edge of the bowl. The self-discharging 2 phase disc separator can be adjusted according to the material.

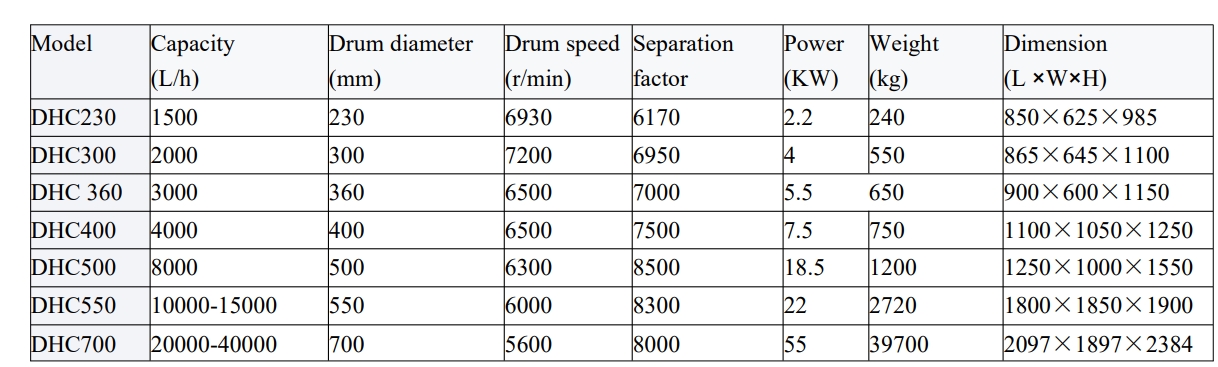

2 Phase Disc Stack Separator Parameter:

Technical Service

- Technical direction when installation, debugging

- Training for operation and maintain worker

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Hot Tags: industrial large capacity centrifuge, China industrial large capacity centrifuge manufacturers, suppliers, factory, centrifuge rotor, 2 Phase Solid Bowl Decanter Centrifuge, clarified apple juice, filtration in wastewater treatment, Large industrial separation equipment, centrifuge for solid liquid separation

customers from other countries visited Shenzhou Group